Genel bakış

Experience reliable, high-performance power generation with our 40KW Mobile Portable Diesel Generator. Engineered with a Cummins 4BT3.9-G2 diesel engine paired with a Stamford UCI224D/S1L2-R1 generator, this mobile power station is designed for heavy-duty applications in various environments. Whether for backup power, construction sites, or remote installations, this generator delivers 40kWe of standby power and 36kWe of continuous power with exceptional efficiency and low noise levels.

Yararlı Bilgiler

-

Innovative Design & Mobility:

Integrated with a robust multi-axle chassis (available in 2-, 3-, 6-, or 8-wheel configurations), our mobile station is built for versatility and easy transportation.

-

Low Noise & Reduced Emissions:

With noise levels ranging from 55 dB(A) to 75 dB(A) measured at 7 Metre, the generator is designed to meet strict environmental standards while keeping operation quiet and clean.

-

Advanced Engineering:

Incorporates a state-of-the-art Cummins diesel engine and high-quality Stamford generator, ensuring stable operation, reduced fuel consumption, and prolonged service life.

-

Sağlam Yapı:

Designed to handle extreme conditions, this generator features a compact and integrated build with fewer parts, minimizing potential failure points and maintenance needs.

Performance Specifications

Motor Özellikleri

-

Dağlamak & Model: Cummins 4BT3.9-G2

-

Konfigürasyon: 4-silindir, Satır içi

-

Yer değiştirme: 3.9 Liters

-

Sıkıştırma Oranı: 16.5:1

-

Cylinder Dimensions: 102 Mm (bore) × 120 Mm (stroke)

-

Yakıt Sistemi: NYC A-type inline pump with rotor high-pressure fuel pump for optimized fuel consumption and lower noise

-

Cooling: Kapalı devre su soğutma

-

Marş Sistemi: DC24V electric starter

-

Yağ Kapasitesi & Pressure: 9 L capacity; 345 kPa oil pressure

-

Design Innovations: Integrated components reduce part count by 40%, enhancing reliability and service life

Jeneratör Özellikleri

-

Dağlamak & Model: Stamford UCI224D/S1L2-R1

-

Kapasite: 50KVA

-

Konfigürasyon: Fırçasız, tek yataklı, with a rotating magnetic field

-

Uyarılma: Otomatik voltaj regülasyonu ile kendinden heyecanlı

-

Winding: 2/3 Tur Sargısı

-

Aşama: Üç fazlı, four-wire connection (Y bağlantısı)

-

İzolasyon Sınıfı: H

-

Güç faktörü: 0.8 gecikmeli

-

Protective Class: IP23 koruma sınıfı

-

Uyma: Meets multiple international standards including GB755, BS5000 Parçası 3, VDE0530, NEMA MG1-22, IEC-34 Serisi, and AS1359

Standard Equipment & Konfigürasyon

-

Engine Unit:

-

Diesel engine with integrated fuel, hava, ve yağ filtreleri

-

Charging system and starter motor

-

Generator Unit:

-

Kontrol sistemi:

-

Supporting Components:

-

Aksesuar -lar:

Çevre & Operasyonel Gereksinimler

-

Yükseklik: E kadar 1000 meters above sea level

-

Ambient Pressure: ≥ 89.9 kPa (İngilizce)

-

Giriş sıcaklığı: ≤ 40°C

-

Yakıt: 0# hafif dizel

-

Oil Specification: CF notu / 15W-40 Zırhlı Hava Yolları

-

Water Quality for Cooling: pH arasında 6.5 ve 8

-

Nem: Relative humidity ≤ 60%

-

Sismik Dayanım: Designed to withstand horizontal acceleration of 0.2g and vertical acceleration of 0.1g

Sertifikalar & Quality Assurance

-

International Standards: Conforms to ISO8528-2005 and GB/T2820-2009 for reciprocating engine-driven AC power systems

-

Kalite Sertifikaları: Manufactured under ISO9001/ISO9002 guidelines

-

Garanti: Backed by a 1-year or 1000-hour warranty covering the entire system, including engine, generator, and control modules

-

Service Network: Comprehensive 24/7 nationwide support and technical assistance

This 40KW Mobile Portable Diesel Generator is an ideal solution for customers seeking a high-performance, reliable, and environmentally friendly power supply. Its innovative design, coupled with industry-leading components, ensures it meets the most rigorous operational demands while delivering exceptional efficiency and durability.

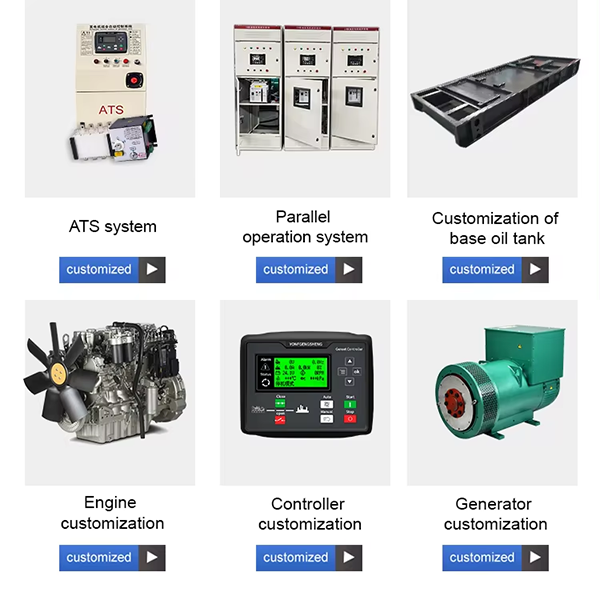

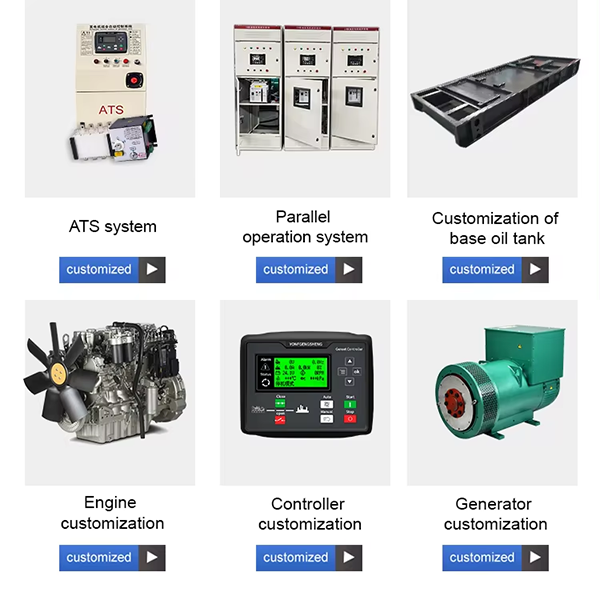

OPSİYONEL FONKSİYON

Contact Us

📧 E-posta: [ gmail@xn-gen.com]

📞 Telefon: [+86 15216161715]

🌐 İnternet sitesi: [xn-gen.com]

For more information or to discuss your specific energy requirements, please contact our sales team. We are committed to delivering efficient and reliable power solutions tailored to your project needs.

Jeneratör Bakım ve Servisi

XN-GEN'de, Profesyonel sağlamak için uzun vadeli bakım anlaşmaları sunuyoruz., yüksek kalite, ve müşterilerimiz için sorunsuz hizmet. Bakım hizmetlerimiz, alternatör setinizin optimum performans ve uzun ömürlü olmasını sağlar. Aşağıda bakım prosedürleri için genel bir kılavuz bulunmaktadır (Belirli eylemlerin her bir jeneratör setinin modeline ve çalışma durumuna bağlı olarak değişebileceğini lütfen unutmayın).

Rutin Bakım

Jeneratörünüzün güvenilirliğini sağlamak için düzenli denetimler ve bakım çok önemlidir. Aşağıdaki kontroller düzenli olarak yapılmalıdır:

- Dönen tüm bileşenleri inceleyin ve gevşek cıvataları sıkın.

- Karterdeki yağ seviyesini kontrol edin ve gerekirse yağ ekleyin.

- Depodaki yakıt seviyelerini izleyin.

- Radyatördeki soğutma sıvısı seviyesini kontrol edin.

- Yakıt ve su boru hatlarında herhangi bir sızıntı veya gevşek bağlantı olup olmadığını inceleyin.

- Emme ve egzoz sistemlerini sağlayın, Silindir contaları ile birlikte, uygun şekilde kapatılmıştır.

- Düzenli bir makine dairesini korumak için jeneratör üzerindeki yağ lekelerini veya toz birikintilerini temizleyin.

Yedek Jeneratörler için Bakım Planı

(Konut topluluklarında kullanılan yedek jeneratörler için önerilir, Ticari Binalar, Hastane, Devlet tesisleri, Turistik, Fabrika, ve elektrik kesintilerinin nadir olduğu diğer yerler.)

Profesyonel Bakım (Her altı ayda bir veya yılda bir)

Rutin bakıma ek olarak, Her altı ayda bir veya yılda bir kez kapsamlı bir hizmet yapılmalıdır:

- Yakıtın kapsamlı bir incelemesini yapın, elektrikli, Soğutma, ve uygun işlevselliği sağlamak için yağlama sistemleri.

- Şunun için yüksüz bir test çalıştırması gerçekleştirin 5-10 sistemi yağlamak için dakika. İşitsel kullanarak jeneratörün performansını değerlendirin, görsel, ve koku alma kontrolleri.

- Sarf malzemesi filtrelerini değiştirin, hava dahil, mazot, yağ, Su, ve yakıt-su separatörleri.

- Soğutma sıvısını boşaltın ve değiştirin, Uygun radyatör fonksiyonunun sağlanması.

- Akü elektrolitini veya damıtılmış suyu gerektiği gibi kontrol edin ve doldurun.

- Bakımı tamamladıktan sonra, Son bir kontrol yapın ve jeneratör setini temizleyin.

- Bir tane daha gerçekleştir 5-10 Dakika yüksüz test, Performans parametrelerini kaydedin, ve müşteri kabulünden önce optimizasyon önerileri sağlayın.

Sürekli Çalışan Jeneratörler için Bakım Planı

(Şantiyelerdeki jeneratörler için önerilir, sık sık elektrik kesintisine meyilli fabrikalar, Trafo kapasitesinin yetersiz olduğu alanlar, Proje test siteleri, veya ana şebekeye erişimi olmayan yerler.)

Düzey 1 Bakım (Her 50-80 Saat)

Bu, tüm rutin bakım görevlerini ve ayrıca şunları içerir:

- Hava filtresini temizleyin ve gerekirse değiştirin.

- Dizel filtresini değiştirin, Hava filtresi, ve su filtresi.

- Tahrik kayışının gerginliğini kontrol edin ve gerekirse ayarlayın.

- Tüm gresörlükleri ve hareketli bileşenleri yağlayın.

- Etkili soğutma performansını korumak için soğutma sıvısını değiştirin.

Düzey 2 Bakım (Her 250-300 Saat)

Seviye içerir 1 Bakım görevleri, ek kontrollerle:

- Pistonları temizleyin ve inceleyin, piston pimleri, Silindir gömlekleri, piston segmanları, ve aşınma için biyel yatakları.

- Ana yatakta herhangi bir gevşeklik veya anormal aşınma belirtisi olup olmadığını inceleyin.

- Uygun ısı dağılımını sağlamak için soğutma sisteminden kireci ve tortuyu çıkarın.

- Yanma odasından ve giriş/çıkış geçişlerinden temiz karbon birikintileri.

- Valf boşluklarını kontrol edin ve ayarlayın, valf yuvaları, İtme çubukları, ve külbütör kolları.

- Turboşarj rotorlarını temizleyin ve yatakları ve pervaneleri aşınma açısından kontrol edin, Gerekirse değiştirme.

- Jeneratör-dizel motor bağlantısındaki gevşemiş veya hasarlı cıvataları sıkın veya değiştirin.

Düzey 3 Bakım (Her 500-1000 Saat)

Seviye içerir 1 ve Seviye 2 Bakım görevleri, ek hizmetlerle birlikte:

- Yakıt enjeksiyon zamanlamasını kontrol edin ve ayarlayın.

- Kirleticileri temizlemek için yakıt deposunu temizleyin.

- Çamur birikmesini önlemek için yağ karterini temizleyin.

- Optimum atomizasyon için yakıt enjektörlerini inceleyin ve test edin.

Bu yapılandırılmış bakım planını takip ederek, Jeneratör sahipleri tutarlı performans sağlayabilir, Artan kullanım ömrü, ve beklenmeyen arıza riskinin azalması. XN-GEN'deki uzman ekibimiz, güç kaynağınızı her zaman güvenilir tutmak için üstün hizmet sunmaya kendini adamıştır.

Daha fazla bilgi almak veya bakım planlamak için, Bugün bize ulaşın!

1. Bir fabrika veya ticaret şirketi misiniz??

Çeşitli jeneratör setlerinin üretiminde uzmanlaşmış bir fabrikayız. Üretim tesisimiz, yüksek kaliteli üretim ve sıkı kalite kontrol sağlar.

2. Ana pazarlarınız hangileri?

Ürünlerimiz yaygın olarak Güney Amerika'ya ihraç edilmektedir, Orta Doğu, Güneydoğu Asya, ve Afrika, Farklı endüstrilerdeki çeşitli güç ihtiyaçlarını karşılar.

3. Ürün kalitesini nasıl sağlıyorsunuz??

Üretimin her aşamasında sıkı kalite kontrol önlemleri uyguluyoruz. Teslimattan önce, Tüm alternatör setleri, optimum performans ve güvenilirlik sağlamak için bir nakliye konteyneri içinde yük testine tabi tutulur.

4. Garanti politikanız nedir?

Ürünlerimiz bir yıllık endüstri standardı garanti ile birlikte gelir veya 1,000 Çalışma Saatleri (hangisi önce gelirse). Ayrıca teknik destek ve yedek parça hizmetleri de veriyoruz.

5. Jeneratörü logomuz veya tasarımımızla özelleştirebilir miyiz??

Evet! Yetkili logolar ve tasarımlar için özel markalama sunuyoruz, jeneratörün görünümünü iş ihtiyaçlarınıza göre kişiselleştirmenize olanak tanır.

6. Teslim süreniz nedir?

Standart üretim ve teslim süremiz içerisindedir 15 Çalışma Günleri, sipariş miktarına ve özelleştirme gereksinimlerine bağlı olarak.

7. Nasıl distribütörünüz olabilirim??

Güçlü pazarlama kaynaklarına ve satış sonrası hizmet yeteneklerine sahip şirketlerle ortaklıkları memnuniyetle karşılıyoruz. Bu kriterleri karşılıyorsanız ve işbirliği yapmakla ilgileniyorsanız, Daha fazla tartışma için bizimle iletişime geçmekten çekinmeyin.

8. Satış sonrası destek sağlıyor musunuz?

Evet! Teknik yardım sunuyoruz, Yedek parça temini, ve jeneratör setlerimizin sorunsuz çalışmasını sağlamak için uzaktan sorun giderme.

9: Kabul edebileceğiniz ödeme koşulları nelerdir??

- A: T / T, 30% pey, 70% teslimattan önce ödenecek;

- veya T/, 30% pey, 70% Görüşte L / C;

- veya 100% Görüşte L / C;

XN-GEN.COM

XN-GEN.COM