Обзор

Experience unparalleled reliability and efficiency with our 140KW Cummins Diesel Generator. Engineered with the renowned Cummins 6BTAA5.9-G12 engine and paired with the Stamford UCI274F1 generator, this high-performance unit delivers a standby power output of 140KW (with a continuous operating power of 120KW) on a standard 50Hz system. Ideal for high-demand environments, it meets rigorous national standards while ensuring low fuel consumption and reduced operating costs.

Ключевые особенности

-

Robust & Reliable Design:

Built to perform under extreme conditions, the integrated design minimizes component count by approximately 40%, significantly reducing potential failure points and maintenance costs.

-

Высокая эффективность:

Advanced engineering ensures optimal fuel usage, with a fuel consumption rate of just 208 g/kW·h, keeping your energy expenses in check without compromising on power delivery.

-

Global Standard Compliance:

Conforms to ISO8528-2005 and GB/T2820-2009 standards for reciprocating engine-driven AC generators, ensuring worldwide reliability and quality.

-

Quality Assurance & Поддержка:

Comes with a 1-year or 1000-hour warranty covering the complete system—including the engine, генератор, and control unit—and is backed by a nationwide 24/7 professional service network.

Технические характеристики

Generator Unit

-

Модель: XN-140CDG

-

Питание в режиме ожидания: 140КВТ

-

Continuous Power: 120КВТ

-

Частота: 50Гц

-

Размеры: 2400 × 840 × 1300 миллиметр

-

Вес: 1300 кг

-

Регулирование напряжения:

-

Регулирование частоты:

Дизель

-

Клеймо: Камминз

-

Модель: 6BTAA5.9-G12

-

Питание в режиме ожидания: 155КВТ

-

Configuration: Inline 6-cylinder

-

Смещение: 5.9 L

-

Диаметр цилиндра x ход поршня: 102 mm × 120 миллиметр

-

Коэффициент уплотнения: 17.3:1

-

Емкость по маслу: 16.4 L

-

Coolant Capacity: 9.9 L (engine only)

-

Топливная система: PB inline pump

-

Система охлаждения: Closed-loop water cooling

-

Метод запуска: DC24V electric starter

-

Воздухозаборник: Turbocharged with intercooler

Generator Details

-

Клеймо: Стамфорд

-

Модель: UCI274F1

-

Способность: 175КВА

-

Voltage Options: 400V/230V

-

Design: Бесщеточный, single-bearing, with a rotating magnetic field

-

Excitation: Self-excited with automatic voltage regulation

-

Конструкция обмотки: 2/3 смола

-

Phase Configuration: Three-phase, four-wire

-

Класс изоляции: H

-

Коэффициент мощности: 0.8 обшивка

-

Connection Method: Y-connected

-

Степень защиты: ИП23

-

Harmonics & Interference:

Environmental & Условия эксплуатации

-

Высота: ≤1000 м

-

Стандарт топлива: 0# легкий дизель

-

Атмосферное давление: ≥89.9 кПа

-

Стандартное масло: Марка CF / 15Ш-40

-

Температура всасывания: ≤40°C

-

Water Quality (pH): 6.5–8.0

-

Относительная влажность воздуха: ≤60%

-

Mildew Resistance: уровень ≤GB/T2423.16/2

-

Seismic Resistance: Горизонтальное ускорение 0,2g, Vertical acceleration 0.1g

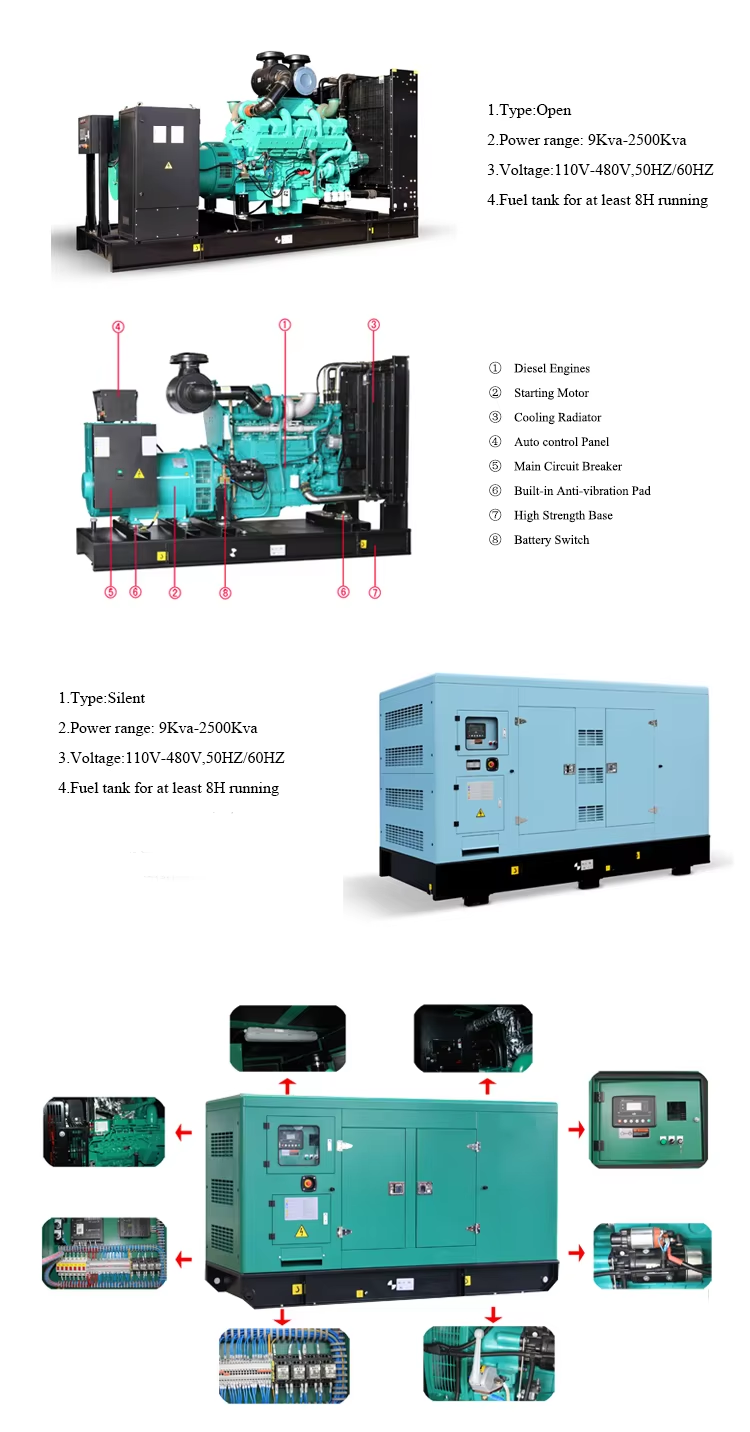

Стандартная конфигурация & Принадлежности

Engine Package:

-

Cummins diesel engine with integrated diesel, air, and oil filters

-

DC24V electric starter and charging system

Generator Package:

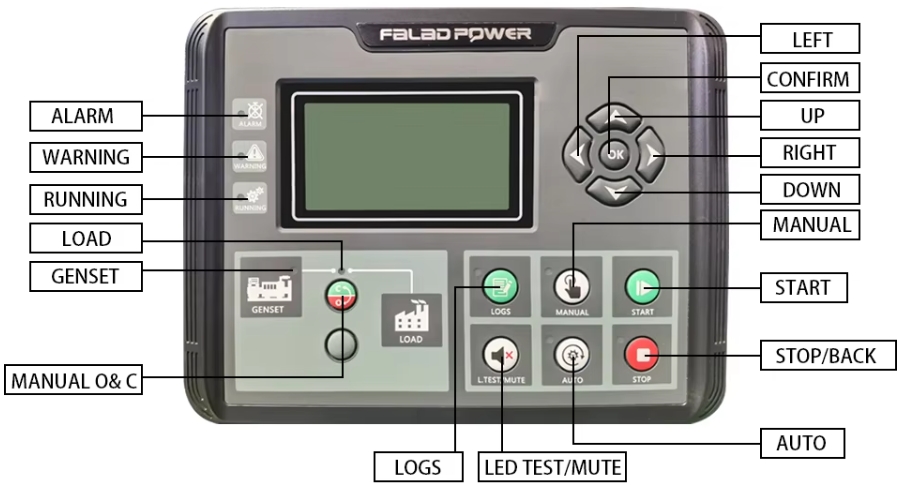

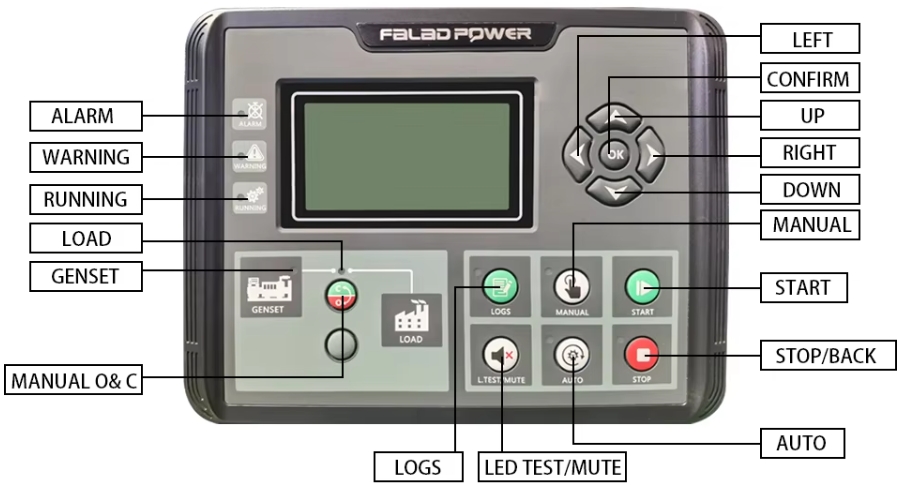

Система управления:

Additional Components:

-

Radiator and water tank cooling system

-

Steel base with vibration dampers

-

Complete set of accessories including silencers, batteries, Кабели для аккумуляторов, масло, and shock pads

Сертификаты & Согласие

Conclusion:

The 140KW Cummins Diesel Generator is a robust, эффективный, and globally certified power solution designed to meet the demands of various high-load applications. Its innovative engineering, combined with comprehensive quality assurance and round-the-clock support, makes it an ideal choice for industries seeking dependable and cost-effective energy solutions.

Product configuration and details

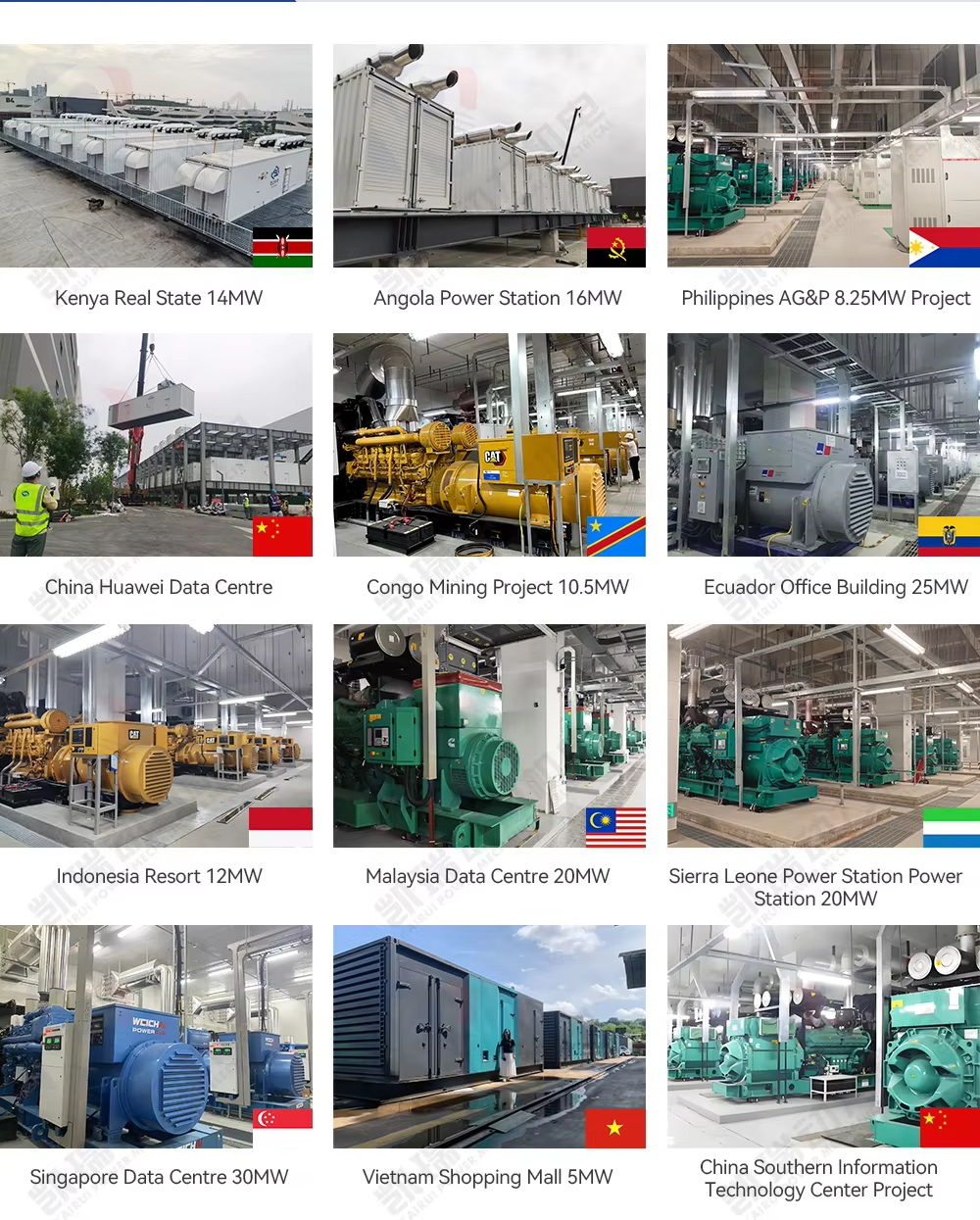

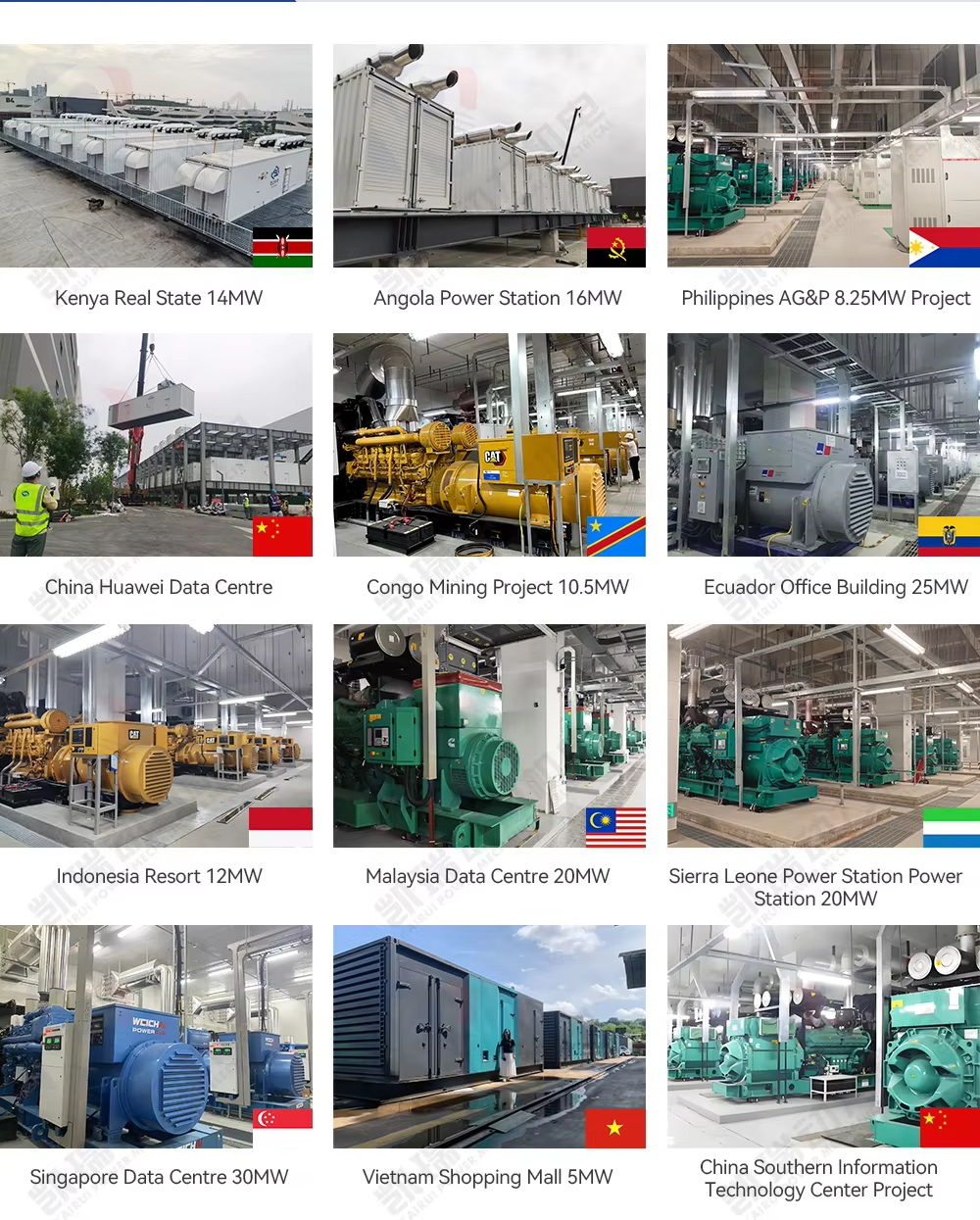

Успешный проект

Логистическая упаковка

Get Your 60KW Cummins Diesel Generator Today!

Whether you need a dependable backup power source for your business or a primary power solution for industrial applications, the 140KW Cummins Diesel Generator is a top-tier choice. Contact us today for pricing, availability, and customization options!

📧 Отправить по электронной почте: [ gmail@xn-gen.com]

📞 Телефон: [+86 15216161715]

🌐 Сайт: [xn-gen.com]

Техническое обслуживание и ремонт генераторов

В XN-GEN, Мы предлагаем долгосрочные договоры на техническое обслуживание, чтобы обеспечить профессиональное, высококачественный, и беспроблемный сервис для наших клиентов. Наши услуги по техническому обслуживанию обеспечивают оптимальную производительность и долговечность вашей генераторной установки. Ниже приведено общее руководство по процедурам технического обслуживания (Обратите внимание, что конкретные действия могут различаться в зависимости от модели и рабочего состояния каждой генераторной установки).

Регламентное техническое обслуживание

Регулярные проверки и техническое обслуживание имеют решающее значение для обеспечения надежности вашего генератора. Следующие проверки должны проводиться регулярно:

- Осмотрите все вращающиеся компоненты и затяните все ослабленные болты.

- Проверьте уровень масла в картере и при необходимости дольте масло.

- Контролируйте уровень топлива в баке.

- Проверьте уровень охлаждающей жидкости в радиаторе.

- Осмотр топливных и водопроводов на наличие утечек или ослабленных соединений.

- Обеспечение впускной и выпускной систем, вместе с прокладками цилиндров, надлежащим образом герметизированы.

- Очистите все масляные пятна или скопления пыли на генераторе для поддержания порядка в машинном помещении.

План технического обслуживания резервных генераторов

(Рекомендуется для резервных генераторов, используемых в жилых районах, Коммерческие здания, Больницы, Государственные учреждения, Туристические достопримечательности, Заводов, и другие места, где перебои в подаче электроэнергии случаются редко.)

Профессиональное обслуживание (Раз в полгода или ежегодно)

В дополнение к плановому обслуживанию, Комплексное обслуживание должно выполняться раз в полгода или раз в год:

- Проведите тщательный осмотр топлива, электрический, охлаждение, и системы смазки для обеспечения надлежащей функциональности.

- Выполнение тестового прогона без нагрузки для 5-10 минут на смазку системы. Оценка производительности генератора с помощью слуховых, зрительный, и обонятельные чеки.

- Замена расходных фильтров, в том числе воздушный, дизель, масло, Вода, и водотопливные сепараторы.

- Слейте и замените охлаждающую жидкость, обеспечение надлежащей работы радиатора.

- Проверьте и пополните электролит аккумулятора или дистиллированную воду по мере необходимости.

- После завершения технического обслуживания, Проведите заключительный осмотр и очистите генераторную установку.

- Выполните еще один 5-10 Минутный тест без нагрузки, Запись параметров производительности, и предоставлять рекомендации по оптимизации до принятия заказчиком.

План технического обслуживания генераторов непрерывного действия

(Рекомендуется для генераторов на строительных площадках, часто подверженные отключениям электроэнергии заводы, Участки с недостаточной трансформаторной мощностью, Тестовые площадки проекта, или места без доступа к основной сети.)

Уровень 1 Содержание (Каждый 50-80 Часов)

Это включает в себя все плановые задачи по техническому обслуживанию плюс:

- Очистите воздушный фильтр и при необходимости замените его.

- Замените дизельный фильтр, воздушный фильтр, и фильтр для воды.

- Проверьте натяжение приводного ремня и при необходимости отрегулируйте его.

- Смазывайте все пресс-масленки и движущиеся компоненты.

- Замените охлаждающую жидкость для поддержания эффективной охлаждающей производительности.

Уровень 2 Содержание (Каждый 250-300 Часов)

Включает уровень 1 Задачи по техническому обслуживанию, с дополнительными проверками:

- Очистка и осмотр поршней, поршневые пальцы, гильзы цилиндров, поршневые кольца, и шатунные подшипники для износа.

- Осмотрите коренной подшипник на наличие признаков ослабления или аномального износа.

- Удалите накипь и осадок из системы охлаждения, чтобы обеспечить надлежащий отвод тепла.

- Удаление нагара из камеры сгорания и впускных/выпускных каналов.

- Осмотр и регулировка зазоров клапанов, Седла клапанов, толкатели, и коромысла.

- Очистите роторы турбокомпрессора и проверьте подшипники и рабочие колеса на предмет износа, замена при необходимости.

- Затяните или замените ослабленные или поврежденные болты в муфте генератор-дизельный двигатель.

Уровень 3 Содержание (Каждый 500-1000 Часов)

Включает уровень 1 и уровень 2 Задачи по техническому обслуживанию, а также дополнительные услуги:

- Проверьте и отрегулируйте момент впрыска топлива.

- Очистите топливный бак для удаления загрязнений.

- Очистите масляный картер для предотвращения накопления шлама.

- Осмотрите и испытайте топливные форсунки для оптимального распыления.

Следуя этому структурированному плану технического обслуживания, Владельцы генераторов могут обеспечить стабильную производительность, увеличенный срок службы, и снижение риска неожиданных отказов. Наша команда экспертов в XN-GEN стремится обеспечить превосходное обслуживание, чтобы ваше электроснабжение всегда было надежным.

Для получения дополнительной информации или планирования технического обслуживания, Свяжитесь с нами сегодня!

1. Вы завод или торговая компания?

Мы являемся заводом, специализирующимся на производстве различных типов генераторных установок. Наше производство обеспечивает высокое качество продукции и строгий контроль качества.

2. Каковы ваши основные рынки?

Наша продукция широко экспортируется в Южную Америку, Ближний Восток, Юго-Восточная Азия, и Африка, Удовлетворение различных потребностей в электроэнергии в различных отраслях промышленности.

3. Как вы обеспечиваете качество продукции?

Мы внедряем строгие меры контроля качества на каждом этапе производства. Перед доставкой, Все генераторные установки проходят нагрузочные испытания внутри транспортного контейнера для обеспечения оптимальной производительности и надежности.

4. Какая у вас гарантийная политика?

На нашу продукцию распространяется стандартная отраслевая гарантия сроком на один год или 1,000 Время работы (в зависимости от того, что наступит раньше). Мы также предоставляем техническую поддержку и услуги по поставке запасных частей.

5. Можем ли мы настроить генератор с помощью нашего логотипа или дизайна?

Да! Мы предлагаем индивидуальный брендинг для авторизованных логотипов и дизайнов, Это позволяет персонализировать внешний вид генератора в соответствии с потребностями вашего бизнеса.

6. Какое у вас время доставки?

Наши стандартные сроки производства и поставки находятся в пределах 15 будни, в зависимости от объема заказа и требований к кастомизации.

7. Как я могу стать вашим дистрибьютором?

Мы приветствуем партнерские отношения с компаниями, которые обладают сильными маркетинговыми ресурсами и возможностями послепродажного обслуживания. Если вы соответствуете этим критериям и заинтересованы в сотрудничестве, Не стесняйтесь обращаться к нам для дальнейших обсуждений.

8. Предоставляете ли вы послепродажную поддержку?

Да! Мы предлагаем техническую поддержку, Поставка запасных частей, и удаленный поиск и устранение неисправностей для обеспечения бесперебойной работы наших генераторных установок.

9: Какие условия оплаты вы можете принять?

- A: Т/Т, 30% задаток, 70% будет оплачен перед доставкой;

- или Т/, 30% задаток, 70% Аккредитив на виду;

- или 100% Аккредитив на виду;

XN-GEN.COM

XN-GEN.COM