Product Description

Cel 2200KW Cummins Diesel Generator combines cutting-edge technology with rugged reliability, making it an ideal power solution for a wide range of demanding applications. Powered by the QSK60-G23 Cummins diesel engine and paired with the S7L1D-J41 Stamford alternator, this generator delivers a standby power of 2200KW and a prime power of 2000KW at 50Hz. Designed to meet stringent global emission standards and built on Cummins’ proven engineering expertise, this V16 four-stroke diesel generator ensures exceptional performance under constant, standby, or continuous operation.

With a rapid start-up time of just 10 Secunde, this generator is perfect for emergency power needs. It also supports fast paralleling, allowing up to 32 units to sync in only 16 Secunde, providing scalable power for large-scale operations. Whether you need backup power for critical infrastructure or a dependable energy source for industrial projects, this Cummins generator guarantees uninterrupted performance when it matters most.

Caracteristici cheie

- High Power Output: Delivers 2200KW standby and 2000KW prime power at 50Hz for robust energy supply.

- Rapid Response: Starts in 10 Secunde, ensuring quick power restoration in emergencies.

- Scalable Design: Parallel up to 32 units in 16 seconds for expanded capacity.

- Advanced Engine: V16 four-stroke diesel with turbocharging and air/water intercooling for superior efficiency.

- Durable Build: Alloy cast iron engine block with replaceable wet cylinder liners for long-lasting performance.

- Fuel Efficiency: High-pressure common rail fuel system optimizes combustion and reduces consumption.

- User-Friendly Controls: Equipped with an LCD digital controller and electronic governor for precise operation.

- Cold Weather Ready: Starts reliably at -7°C without auxiliary aids.

- Certified Quality: Meets ISO8528-2005 and GB/T2820-2009 standards for assured reliability.

Specificații tehnice

General Specifications

| Parametru |

Detalii |

| Model |

XN-2200CDG |

| Type |

Open Frame |

| Alimentare în standby |

2200KW |

| Putere principală |

2000KW |

| Frecvență |

50Hz |

| Voltaj |

400V/230V |

| Dimensiuni (L x W x H) |

7180 x 2384 x 3403 milimetru |

| Greutate |

24,709 Kg |

| Consumul |

193 g/kW.h |

Specificațiile motorului

| Parametru |

Detalii |

| Marcă |

Cummins |

| Model |

QSK60-G23 |

| Origin |

UK (Cummins Inc.) |

| Type |

V16, Four-Stroke |

| Max Power |

2388KW |

| Rated Power |

2157KW |

| Deplasament |

60.2L |

| Bore x Stroke |

159 x 190 milimetru |

| Raport de compresie |

14.5:1 |

| Sistem de răcire |

Closed Water-Cooled |

| Sistemul de alimentare cu combustibil |

High-Pressure Common Rail |

| Starting System |

DC24V Electric Start |

| Intake System |

Turbocompresor, Intercooled |

Alternator Specifications

| Parametru |

Detalii |

| Marcă |

Stamford |

| Model |

S7L1D-J4 |

| Rated Capacity |

2500KVA |

| Type |

Brushless, Single Bearing |

| Excitation |

Self-Excited, AVR |

| Clasa de izolație |

H |

| Grad de protecție |

IP23 |

| Power Factor |

0.8 Lagging |

| Connection |

Y-Type |

Performance Parameters

- Voltage Regulation:

- Transient: ≤-15%/+20%

- Steady: ≤±1%

- Stabilization Time: ≤3s

- Fluctuation: ≤0.5%

- Frequency Regulation:

- Steady: ≤5%

- Transient: ≤-10%/+12%

- Stabilization Time: 3s

- Fluctuation: ≤1.5%

Cerințe de mediu

- Altitudine: ≤1000m

- Temperatura ambiantă: ≤40°C

- Umiditate relativă: ≤60%

- Fuel: 0# Light Diesel

- Oil: CF Grade/15W-40

- Water Quality: Ph 6.5-8

Aplicaţii

Cel 2200KW Cummins Diesel Generator is engineered to meet diverse power needs, inclusiv:

- Industrial Use: Reliable backup or primary power for factories, mining sites, and construction projects.

- Commercial Facilities: Ensures continuity for hospitals, data centers, and office buildings.

- Emergency Power: Fast-start capability for critical systems during outages.

- Event Power: Supports large outdoor events with consistent, high-capacity energy.

Garanție și asistență

Cummins backs this generator with a 1-an sau garanție de 1000 de ore, covering the engine, alternator, și sistem de control. Our nationwide service network offers 24-hour technical support and after-sales assistance to keep your generator running smoothly.

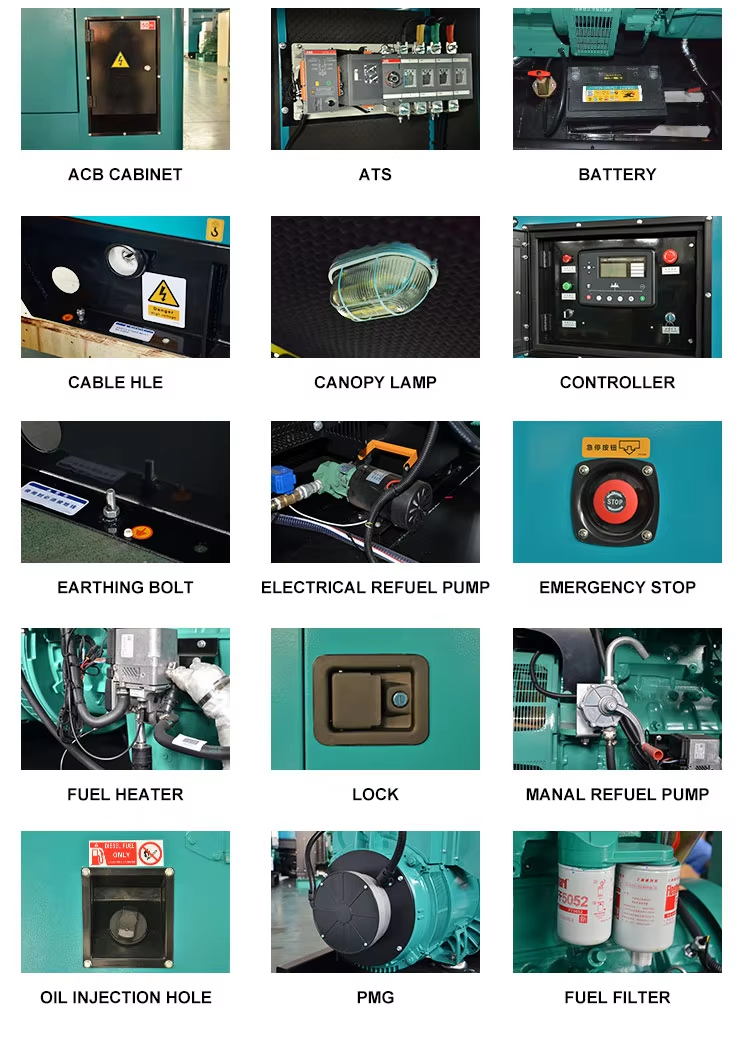

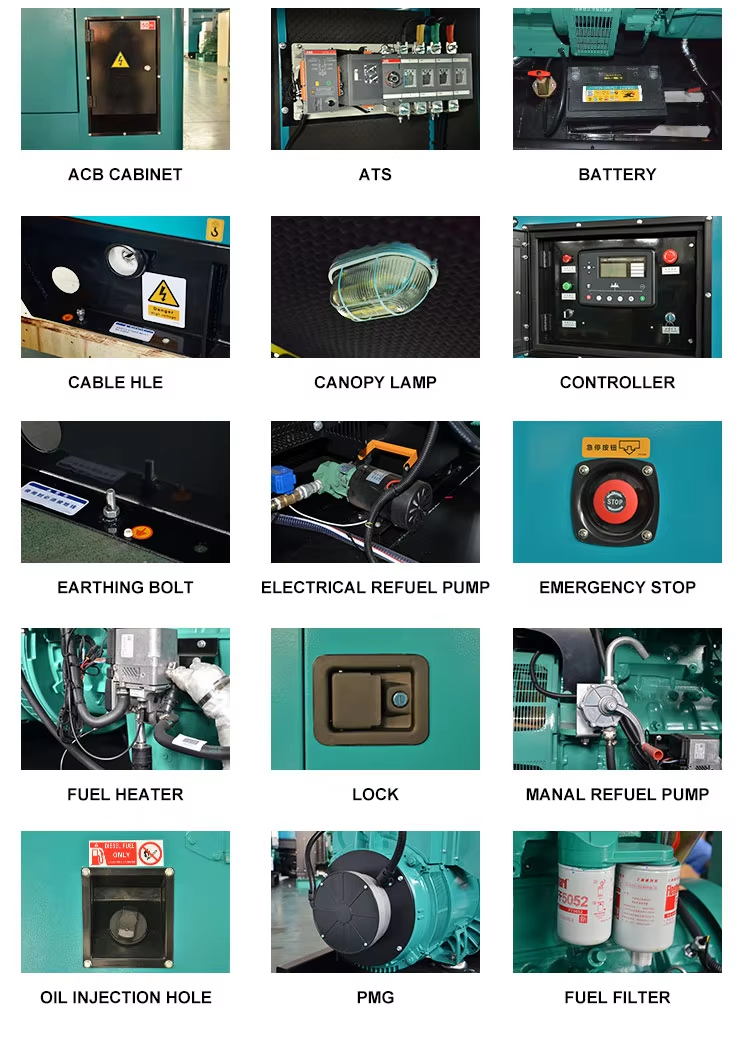

Configurații opționale

Enhance your generator with these customizable options:

- ATS (Automatic Transfer Switch): Seamless power switching during outages.

- Paralleling Cabinet: Automatic syncing with Deep Sea DSE control module.

- Containerized Unit: Portable and weather-resistant design.

- Mobile Trailer: On-the-go power for remote locations.

- Rainproof Canopy: Protection for outdoor use.

- Silent Option: Reduced noise for sensitive environments.

- Monitorizare de la distanță: Computer interface for real-time control.

Why Choose the 2200KW Cummins Diesel Generator?

This generator combines power, speed, and durability in a single package. With its quick-start technology, scalable paralleling capabilities, and Cummins’ trusted engineering, it’s the perfect choice for businesses and organizations needing dependable energy solutions.

Contact Us Today

Need a powerful and reliable generator for your next project? Get in touch with our team to learn more about the 2200KW Cummins Diesel Generator or request a personalized quote. Let us help you keep the lights on and your operations running!

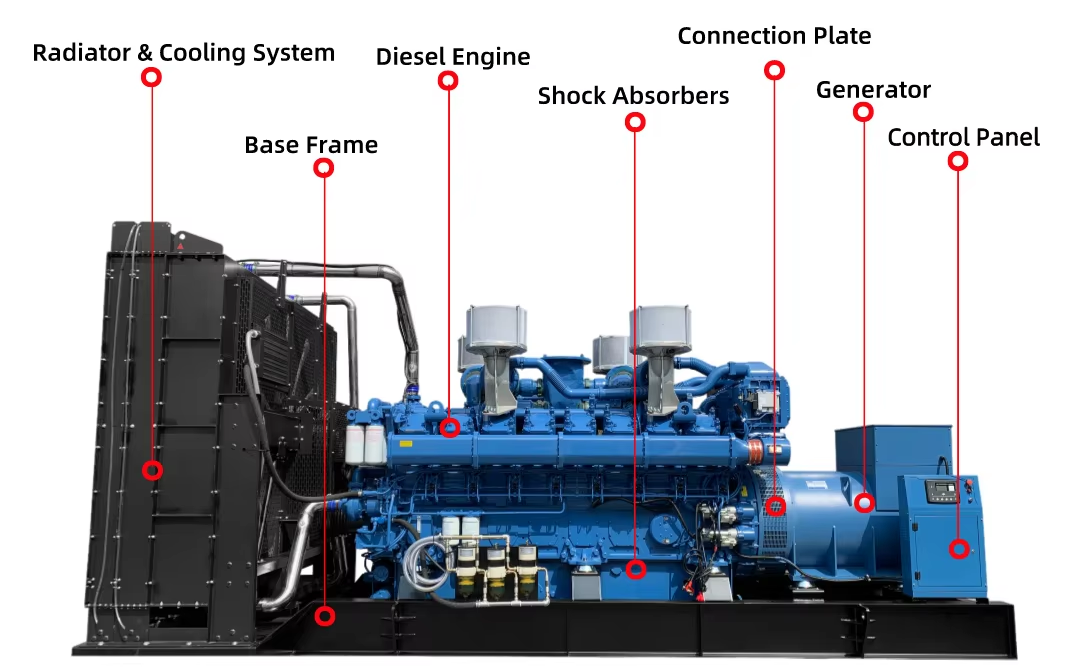

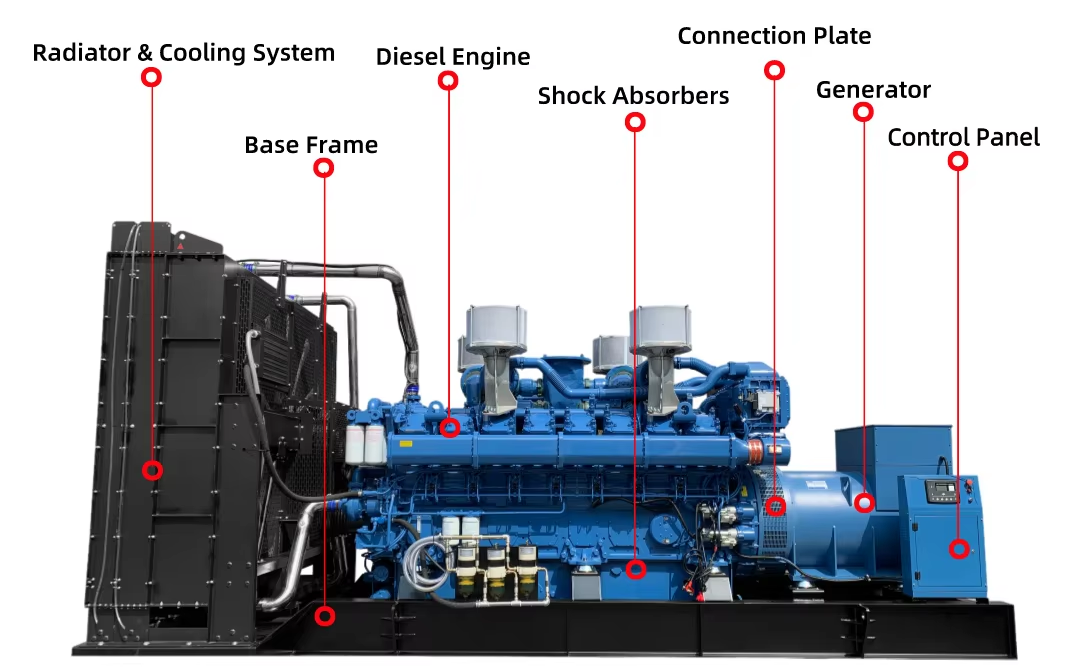

Generator Set Structure-Silent Type

FUNCȚIE OPȚIONALĂ

Ambalaje logistice

Contact & Sprijini

For more detailed information or to discuss customized power solutions, please contact our sales and support team. Our dedicated professionals are available 24/7 to assist you with product selection, installation guidance, and after-sales service.

📧 E-mail: [ gmail@xn-gen.com]

📞 Telefon: [+86 15216161715]

🌐 Site-ul web: [xn-gen.com]

Întreținerea și întreținerea generatorului

La XN-GEN, oferim contracte de întreținere pe termen lung pentru a oferi, de înaltă calitate, și servicii fără probleme pentru clienții noștri. Serviciile noastre de întreținere asigură performanța optimă și longevitatea grupului dumneavoastră electrogen. Mai jos este un ghid general pentru procedurile de întreținere (Vă rugăm să rețineți că acțiunile specifice pot varia în funcție de modelul și starea de funcționare a fiecărui grup electrogen).

Întreținere de rutină

Inspecțiile și întreținerea periodică sunt esențiale pentru a asigura fiabilitatea generatorului dumneavoastră. Următoarele verificări trebuie efectuate în mod regulat:

- Inspectați toate componentele rotative și strângeți orice șuruburi slăbite.

- Verificați nivelul uleiului din carter și adăugați ulei dacă este necesar.

- Monitorizați nivelurile de combustibil din rezervor.

- Inspectați nivelul lichidului de răcire din radiator.

- Examinați conductele de combustibil și apă pentru orice scurgeri sau conexiuni slăbite.

- Asigurați sistemele de admisie și evacuare, împreună cu garniturile cilindrilor, sunt sigilate corespunzător.

- Curățați orice pete de ulei sau acumulare de praf pe generator pentru a menține o cameră de mașini ordonată.

Planul de întreținere pentru generatoarele de rezervă

(Recomandat pentru generatoarele de rezervă utilizate în comunitățile rezidențiale, Clădiri comerciale, Spitale, facilități guvernamentale, Obiective turistice, Fabrici, și alte locații în care întreruperile de curent sunt rare.)

Întreținere profesională (La fiecare șase luni sau anual)

Pe lângă întreținerea de rutină, Un serviciu cuprinzător ar trebui efectuat la fiecare șase luni sau o dată pe an:

- Efectuați o inspecție amănunțită a combustibilului, electric, Răcire, și sisteme de lubrifiere pentru a asigura o funcționalitate adecvată.

- Efectuați un test fără sarcină pentru 5-10 minute pentru lubrifierea sistemului. Evaluați performanța generatorului folosind, Visual, și verificări olfactive.

- Înlocuiți filtrele consumabile, inclusiv aerul, motorină, ulei, Apă, și separatoare combustibil-apă.

- Scurgeți și înlocuiți lichidul de răcire, asigurarea funcționării corecte a radiatorului.

- Verificați și completați electrolitul bateriei sau apa distilată, după cum este necesar.

- După finalizarea întreținerii, efectuați o inspecție finală și curățați grupul electrogen.

- Efectuați un alt 5-10 Test minut fără sarcină, Înregistrați parametrii de performanță, și oferă recomandări de optimizare înainte de acceptarea de către clienți.

Plan de întreținere pentru generatoare cu funcționare continuă

(Recomandat pentru generatoare pe șantierele de construcții, fabrici predispuse frecvent la întreruperi de curent, zone cu capacitate insuficientă a transformatorului, Site-uri de testare a proiectului, sau locații fără acces la rețeaua principală.)

Nivel 1 Întreținere (Fiecare 50-80 Ore)

Aceasta include toate sarcinile de întreținere de rutină plus:

- Curățați filtrul de aer și înlocuiți-l dacă este necesar.

- Înlocuiți filtrul de motorină, filtru de aer, și filtru de apă.

- Inspectați tensiunea curelei de transmisie și reglați dacă este necesar.

- Lubrifiați toate armăturile de lubrifiere și componentele mobile.

- Înlocuiți lichidul de răcire pentru a menține performanța de răcire eficientă.

Nivel 2 Întreținere (Fiecare 250-300 Ore)

Include nivelul 1 Sarcini de întreținere, cu verificări suplimentare:

- Curățați și inspectați pistoanele, știfturi de piston, căptușeli de cilindru, inele de piston, și rulmenți de biela pentru uzură.

- Examinați rulmentul principal pentru orice semne de slăbiciune sau uzură anormală.

- Îndepărtați depunerile și sedimentele din sistemul de răcire pentru a asigura disiparea corectă a căldurii.

- Eliminarea depunerilor de carbon din camera de ardere și din pasajele de admisie/evacuare.

- Inspectați și reglați jocurile supapelor, Scaune de supape, tije de împingere, și balansoare.

- Curățați rotoarele turbocompresorului și verificați uzura rulmenților și rotoarelor, înlocuirea dacă este necesar.

- Strângeți sau înlocuiți orice șuruburi slăbite sau deteriorate din cuplajul generator-motor diesel.

Nivel 3 Întreținere (Fiecare 500-1000 Ore)

Include nivelul 1 și nivel 2 Sarcini de întreținere, împreună cu servicii suplimentare:

- Verificați și reglați sincronizarea injecției de combustibil.

- Curățați rezervorul de combustibil pentru a elimina contaminanții.

- Curățați baia de ulei pentru a preveni acumularea de nămol.

- Inspectați și testați injectoarele de combustibil pentru o atomizare optimă.

Urmând acest plan de întreținere structurat, Proprietarii de generatoare pot asigura performanțe constante, durată de viață crescută, și risc redus de defecțiuni neașteptate. Echipa noastră de experți de la XN-GEN este dedicată furnizării de servicii superioare pentru a vă menține sursa de alimentare fiabilă în orice moment.

Pentru mai multe informații sau pentru a programa întreținerea, Contactați-ne astăzi!

1. Sunteți o fabrică sau o companie comercială?

Suntem o fabrică specializată în producția de diferite tipuri de grupuri electrogene. Unitatea noastră de producție asigură o producție de înaltă calitate și un control strict al calității.

2. Care sunt principalele piețe?

Produsele noastre sunt exportate pe scară largă în America de Sud, Orientul Mijlociu, Asia de Sud-Est, și Africa, Satisfacerea diverselor nevoi de energie din diferite industrii.

3. Cum asigurați calitatea produsului?

Implementăm măsuri stricte de control al calității în fiecare etapă a producției. Înainte de livrare, Toate grupurile electrogene sunt supuse testării de încărcare în interiorul unui container de transport pentru a asigura performanțe și fiabilitate optime.

4. Care este politica de garanție?

Produsele noastre vin cu o garanție standard de un an sau 1,000 Program de funcționare (oricare dintre acestea survine mai întâi). De asemenea, oferim asistență tehnică și servicii de piese de schimb.

5. Putem personaliza generatorul cu logo-ul sau designul nostru?

Da! Oferim branding personalizat pentru logo-uri și modele autorizate, permițându-vă să personalizați aspectul generatorului în funcție de nevoile afacerii dvs.

6. Care este timpul de livrare?

Timpul nostru standard de producție și livrare este în 15 zile lucrătoare, în funcție de cantitatea comenzii și de cerințele de personalizare.

7. Cum pot deveni distribuitorul tău?

Salutăm parteneriatele cu companii care au resurse puternice de marketing și capacități de servicii post-vânzare. Dacă îndepliniți aceste criterii și sunteți interesat să colaborați, Nu ezitați să ne contactați pentru discuții suplimentare.

8. Oferiți asistență post-vânzare?

Da! Oferim asistență tehnică, Furnizarea de piese de schimb, și depanare de la distanță pentru a asigura funcționarea fără probleme a grupurilor noastre electrogene.

9: Care sunt condițiile de plată pe care le puteți accepta?

- Un: T / T, 30% depunere, 70% va fi plătit înainte de livrare;

- sau T/, 30% depunere, 70% L/C la vedere;

- sau 100% L/C la vedere;

XN-GEN.COM

XN-GEN.COM