Overview

The XN-360KW Diesel Generator is designed for reliable and efficient power generation in industrial and commercial applications. With a robust 360KW rated power capacity and advanced features, this generator ensures maximum performance and durability.

Especificações principais

- Modelo: XN-360GFS

- Rated Power: 360KW / 450KVA

- Alimentação em standby: 400KW / 500KVA

- Rated Current: 630Um

- Dimensões: 3300em milímetro (L) x 1400mm (W) x 1750mm (H)

- Peso: 2800kg

Engine Details

The XN-360GFS diesel generator is powered by a high-performance 6ETAA12.8-G31 engine, designed to provide a dependable and energy-efficient solution. The engine operates at a rated speed of 1500 RPM, and features a four-stroke, in-line configuration. It is equipped with a fan water-cooling system and meets the ISO3046 standard.

- Engine Model: 6ETAA12.8-G31

- Power Output: 401KW / 441HP

- Bore x Stroke: 130mm x 161mm

- Cylinders: 6

- Deslocamento: 12.8L

- Taxa de compressão: 17:1

- Turbocharged & Intercooled: Sim

- Exhaust Temperature: 600°C

Cooling and Lubrication System

The XN-360GFS is equipped with a freshwater circulation cooling system that guarantees optimal engine performance, even under heavy load conditions.

- Cooling Liquid Capacity: 23.2L

- Maximum Coolant Temperature: 102°C

- Water Temperature Range: 82-93°C

- Maximum Oil Temperature: 103°C

- Lubricating Oil Capacity: 36L

- Rated Fuel Consumption: 70.1L/h

- Speed Control: Electronic Governor

Alternator Details

The generator is fitted with an XN-brand synchronous alternator, built to meet global standards such as GB755, BS5000, VDE0530, IEC34-1, CSA22.2, and AS2359. This high-efficiency alternator ensures consistent power output.

- Rated Voltage: 400V / 230V

- Generator Model: JXXN-360

- Capacidade Nominal: 360KW / 450KVA

- Eficiência: 93.7%

- Fator de potência: 0.8 (Lagging)

- Sistema de Excitação: Brushless Self-excited

- Max Voltage Regulation: ±1%

- Phases: 3 Phase

- Protection Level: IP23

- Classe de isolamento: F

Sistema de Controlo

The XN-360KW Diesel Generator comes equipped with the advanced HGM6110 automatic control system. It features a user-friendly LED integrated display for easy monitoring of key parameters. The system also includes alarms and protection signals for added safety and convenience.

- Painel de Controlo: HGM6110

- Battery: 2x120AH 12V

Caraterísticas & Benefits

- High Reliability: Engineered for long-term use with minimal maintenance, providing stable power even in the most demanding conditions.

- Eficiência: Low fuel consumption and high power output, making it a cost-effective choice for commercial and industrial applications.

- Safety: Comprehensive protection systems to prevent damage from electrical faults, overheating, and other risks.

- Advanced Control: The intuitive control system allows for easy operation and monitoring, ensuring seamless performance.

- Versatility: Ideal for a wide range of applications, including backup power for businesses, Estaleiros de Obras, and critical infrastructure.

Aplicações

- Industrial Power Generation

- Commercial Establishments

- Estaleiros de Obras

- Data Centers and IT Infrastructure

- Agricultural Operations

- Mining and Heavy Equipment Operations

Technical drawings:

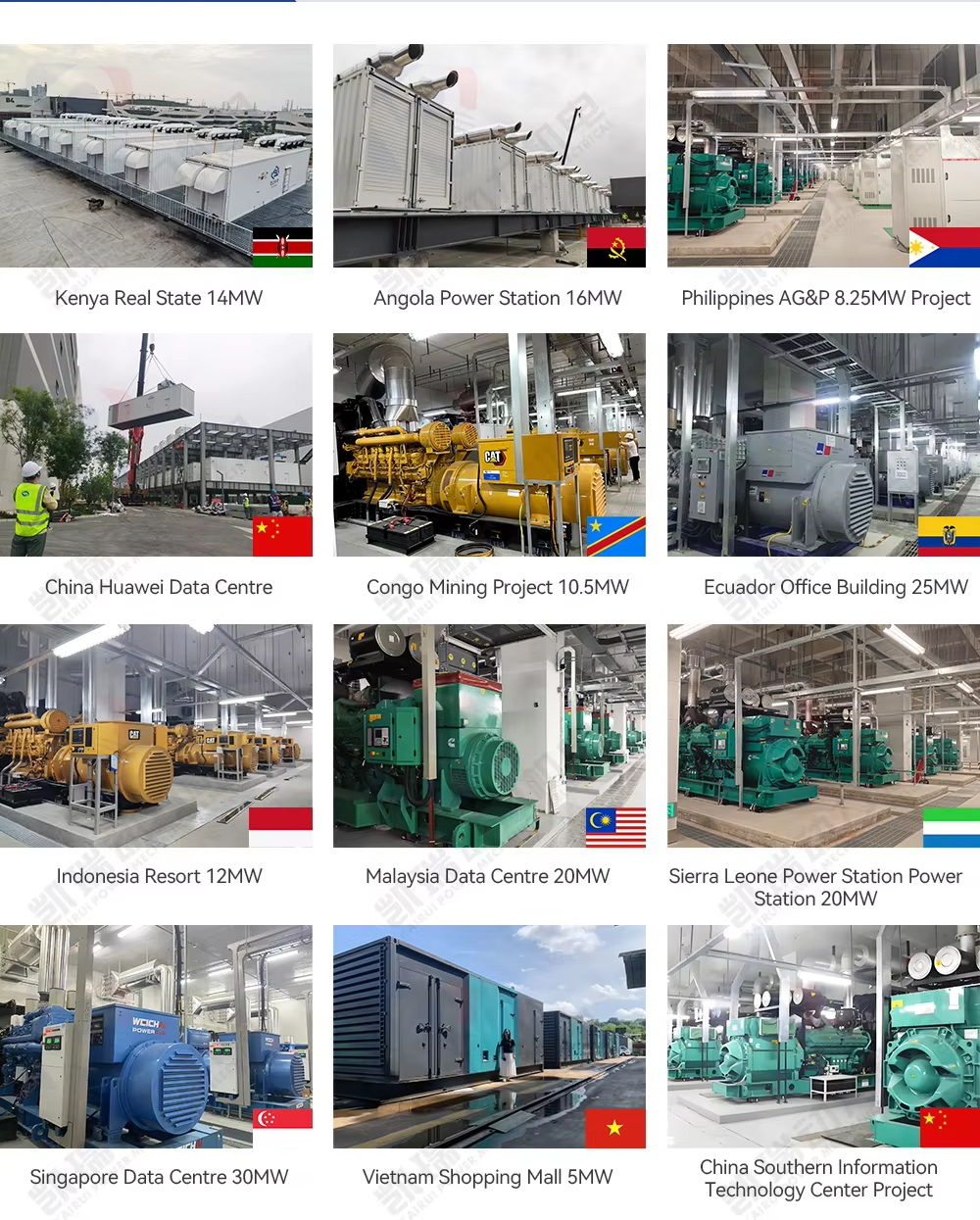

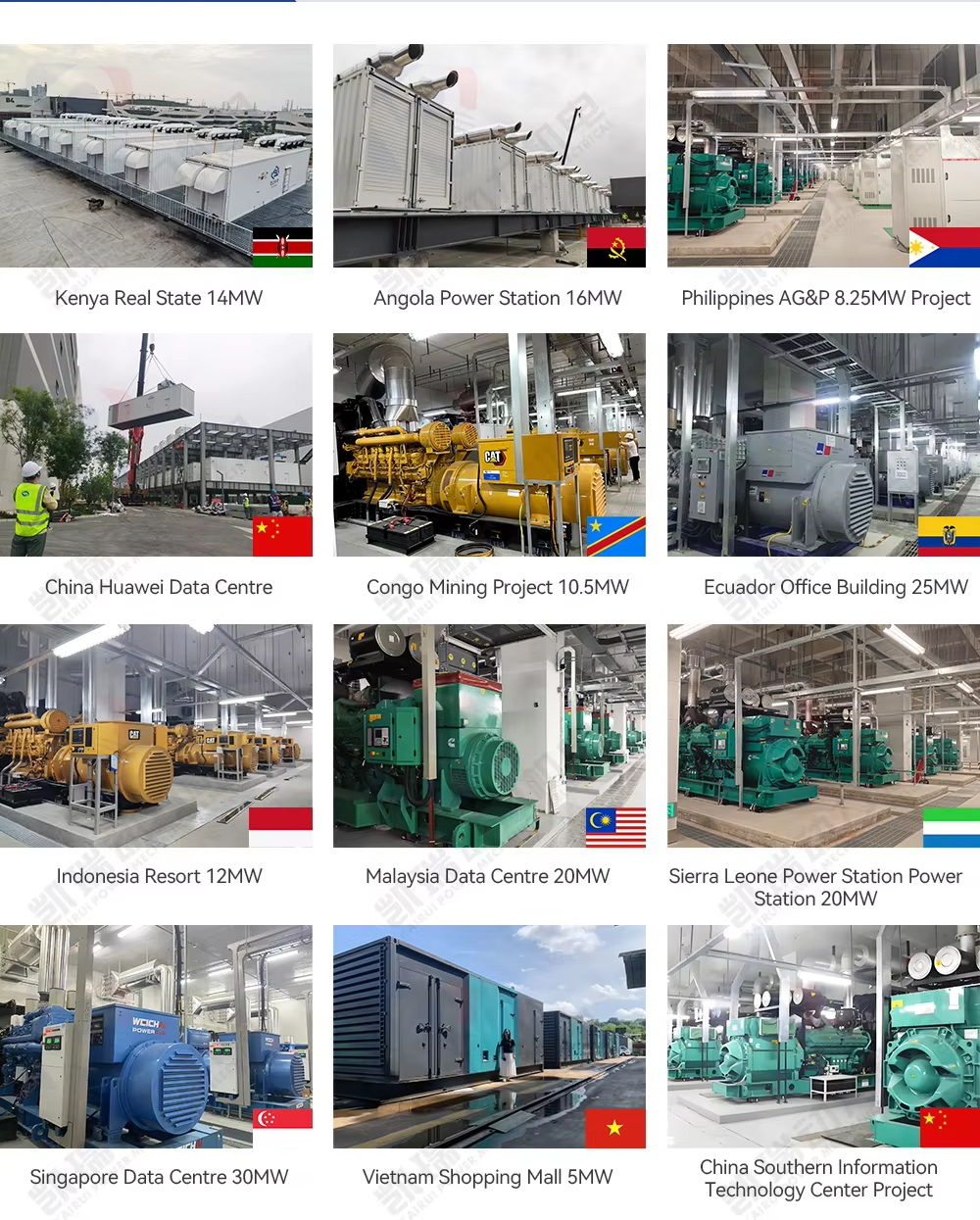

Successful Project

Logística de Embalagens

Why Choose XN-360KW Diesel Generator?

With superior performance, reliability, and energy efficiency, the XN-360KW Diesel Generator is an excellent investment for industries requiring continuous and reliable power. The generator meets international standards, ensuring a robust and dependable solution for various high-demand environments.

📧 Email: [ gmail@xn-gen.com]

📞 Telefone: [+86 15216161715]

🌐 Sítio Web: [xn-gen.com]

Manutenção e Manutenção de Geradores

Na empresa XN-GEN, Oferecemos contratos de manutenção de longo prazo para fornecer, alta qualidade, e serviço sem complicações para os nossos clientes. Nossos serviços de manutenção garantem o desempenho ideal e a longevidade do seu grupo gerador. Segue-se uma orientação geral para os procedimentos de manutenção (Observe que ações específicas podem variar de acordo com o modelo e o status operacional de cada grupo gerador).

Manutenção de Rotina

Inspeções regulares e manutenção são cruciais para garantir a confiabilidade do seu gerador. Devem ser efetuados regularmente os seguintes controlos:

- Inspecione todos os componentes rotativos e aperte os parafusos soltos.

- Verifique o nível de óleo no cárter e adicione óleo, se necessário.

- Monitore os níveis de combustível no tanque.

- Inspecione o nível de refrigerante no radiador.

- Examine as tubulações de combustível e água em busca de vazamentos ou conexões soltas.

- Assegurar os sistemas de admissão e de escape, juntamente com juntas de cilindro, estão devidamente seladas.

- Limpe quaisquer manchas de óleo ou acúmulo de poeira no gerador para manter uma sala de máquinas arrumada.

Plano de Manutenção de Geradores em Standby

(Recomendado para geradores de backup usados em comunidades residenciais, Edifícios Comerciais, Hospitais, Instalações governamentais, atrações turísticas, Fábricas, e outros locais onde as quedas de energia são raras.)

Manutenção Profissional (De seis em seis meses ou anualmente)

Além da manutenção de rotina, Um serviço abrangente deve ser realizado a cada seis meses ou uma vez por ano:

- Realizar uma inspeção completa do combustível, elétrica, arrefecimento, e sistemas de lubrificação para garantir a funcionalidade adequada.

- Execute um teste sem carga para 5-10 minutos para lubrificar o sistema. Avaliar o desempenho do gerador utilizando a audição, visuais, e controlos olfativos.

- Substitua filtros consumíveis, incluindo ar, gasóleo, óleo, Água, e separadores combustível-água.

- Escorra e substitua o líquido de arrefecimento, garantir o funcionamento adequado do radiador.

- Verifique e reabasteça o eletrólito da bateria ou a água destilada conforme necessário.

- Após concluir a manutenção, realizar uma inspeção final e limpar o grupo gerador.

- Executar outro 5-10 Teste minuto sem carga, Registar parâmetros de desempenho, e fornecer recomendações de otimização antes da aceitação do cliente.

Plano de Manutenção de Geradores de Operação Contínua

(Recomendado para geradores em canteiros de obras, fábricas frequentemente propensas a cortes de energia, Áreas com capacidade insuficiente do transformador, Locais de teste do projeto, ou locais sem acesso à rede principal.)

Nível 1 Manutenção (Todos os 50-80 Horário)

Isso inclui todas as tarefas de manutenção de rotina e:

- Limpe o filtro de ar e substitua-o, se necessário.

- Substitua o filtro diesel, filtro de ar, e filtro de água.

- Inspecione a tensão da correia de transmissão e ajuste se necessário.

- Lubrifique todos os acessórios de graxa e componentes móveis.

- Substitua o líquido de arrefecimento para manter um desempenho de arrefecimento eficaz.

Nível 2 Manutenção (Todos os 250-300 Horário)

Inclui Nível 1 tarefas de manutenção, com verificações adicionais:

- Limpar e inspecionar pistões, pinos de pistão, revestimentos de cilindros, Anéis de pistão, e rolamentos de bielas para desgaste.

- Examine o rolamento principal para verificar se há sinais de frouxidão ou desgaste anormal.

- Remova a incrustação e o sedimento do sistema de resfriamento para garantir a dissipação de calor adequada.

- Depósitos de carbono limpo da câmara de combustão e passagens de admissão/escape.

- Inspecionar e ajustar as folgas das válvulas, assentos de válvula, hastes de empurrar, e braços basculantes.

- Limpe os rotores do turbocompressor e verifique o desgaste dos rolamentos e impulsores, substituição, se necessário.

- Apertar ou substituir quaisquer parafusos soltos ou danificados no acoplamento gerador-motor diesel.

Nível 3 Manutenção (Todos os 500-1000 Horário)

Inclui Nível 1 e Nível 2 tarefas de manutenção, juntamente com serviços adicionais:

- Verifique e ajuste a regulação da injeção de combustível.

- Limpe o tanque de combustível para remover contaminantes.

- Limpe o reservatório de óleo para evitar o acúmulo de lodo.

- Inspecione e teste os injetores de combustível para uma atomização ideal.

Seguindo este plano de manutenção estruturado, Os proprietários de geradores podem garantir um desempenho consistente, aumento da vida útil, e redução do risco de falhas inesperadas. A nossa equipa de especialistas na XN-GEN dedica-se a fornecer um serviço superior para manter a sua fonte de alimentação fiável em todos os momentos.

Para mais informações ou para agendar a manutenção, Contacte-nos hoje!

1. Você é uma fábrica ou uma empresa comercial?

Somos uma fábrica especializada na produção de vários tipos de grupos geradores. Nossa instalação de fabricação garante produção de alta qualidade e rigoroso controle de qualidade.

2. Quais são os seus principais mercados?

Nossos produtos são amplamente exportados para a América do Sul, Médio Oriente, Sudeste Asiático, e África, atender a diversas necessidades de energia em diferentes setores.

3. Como você garante a qualidade do produto?

Implementamos rigorosas medidas de controlo de qualidade em todas as fases da produção. Antes da entrega, Todos os grupos geradores passam por testes de carga dentro de um contêiner de transporte para garantir o desempenho e a confiabilidade ideais.

4. Qual é a sua política de garantia?

Nossos produtos vêm com uma garantia padrão da indústria de um ano ou 1,000 Horário de funcionamento (o que ocorrer primeiro;). Também fornecemos suporte técnico e serviços de peças de reposição.

5. Podemos personalizar o gerador com o nosso logotipo ou design?

Sim! Oferecemos marcas personalizadas para logotipos e designs autorizados, permitindo que você personalize a aparência do gerador de acordo com as necessidades do seu negócio.

6. Qual é o seu prazo de entrega?

Nossa produção padrão e tempo de entrega está dentro 15 dias úteis, dependendo da quantidade do pedido e dos requisitos de personalização.

7. Como posso tornar-me seu distribuidor?

Aceitamos parcerias com empresas que tenham fortes recursos de marketing e capacidades de serviço pós-venda. Se você atende a esses critérios e está interessado em colaborar, não hesite em contactar-nos para mais discussões.

8. Você fornece suporte pós-venda?

Sim! Oferecemos assistência técnica, fornecimento de peças de reposição, e solução de problemas remota para garantir a operação perfeita de nossos grupos geradores.

9: Quais são as condições de pagamento que pode aceitar?

- Um: T/T, 30% depósito, 70% será pago antes da entrega;

- ou T/, 30% depósito, 70% L/C na mira;

- quer 100% L/C na mira;

XN-GEN.COM

XN-GEN.COM