Overview

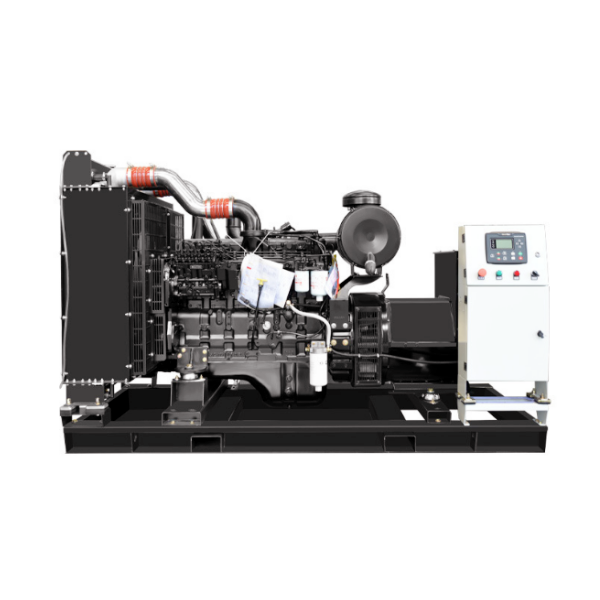

The 120kW Cummins Diesel Generator is engineered for demanding applications and extreme environments. Powered by the robust Cummins 6BTAA5.9-G2 engine and paired with a high-quality UCI274E1 Stamford generator, this unit delivers a backup power output of 120kW (with a common working power of 105kW). Its advanced cold-start capabilities, thanks to a sophisticated intake pre-heating system and high-power starter motor, ensure rapid startup even in frigid temperatures. Designed for durability and ease of maintenance, this generator is ideal for industries requiring reliable power under harsh operating conditions.

Key Features

-

Superior Cold-Start Performance:

Equipped with an intake pre-heating system and a high-torque electric starter, the generator can start quickly in low-temperature environments, reducing downtime in extreme weather. -

Robust Design and Manufacturing:

Built to meet international standards (ISO8528-2005, GB/T2820-2009) and manufactured under strict quality controls (ISO9001/ISO9002 certified), ensuring long service life and reliable operation under heavy load and harsh conditions. -

Optimized Engine Design:

The integrated cylinder block and head design minimizes parts by approximately 40%, significantly reducing potential leak points and maintenance needs. -

Advanced Turbocharging and Fuel Filtration:

Featuring a Holset turbocharger with an integrated bypass valve for excellent low-speed response and a three-stage fuel filtration system that prolongs engine life by maintaining balanced particle dispersion. -

Comprehensive Warranty & Support:

Backed by a 1-year or 1000 running hours warranty, along with 24/7 nationwide technical support to keep your operations running smoothly.

Technical Specifications

Generator Set Specifications

-

Model: XN-120CDG (Open Frame)

-

Backup Power: 120kW

-

Common Power: 105kW

-

Dimensions: 2400 x 840 x 1300 mm

-

Weight: 1200 kg

-

Operating Speed: 1500 rpm

-

Fuel Consumption: 208 g/kW·h

-

Frequency: 50 Hz

Voltage & Frequency Stability

-

Transient Voltage Regulation: ≤ -15% / +20%

-

Steady State Voltage Regulation: ±1% (stabilization within 3 sec)

-

Voltage Ripple: ≤ 0.5%

-

Waveform Distortion: ≤ 8%

-

Steady State Frequency Regulation: ≤ 5%

-

Transient Frequency Regulation: -10% / +12%

-

Frequency Stability Time: 3 sec

-

Frequency Ripple: ≤ 1.5%

Engine Specifications

-

Engine Model: Cummins 6BTAA5.9-G2

-

Manufacturer: Dongfeng Cummins Engine Co., Ltd.

-

Backup Engine Power: 130kW

-

Configuration: 6-cylinder inline

-

Compression Ratio: 16.5:1

-

Bore x Stroke: 102 mm x 120 mm

-

Displacement: 5.9 L

-

Oil Pressure: 345 kPa

-

Maximum Oil Temperature: ≤ 121°C

-

Oil Capacity: 16.4 L

-

Cooling Water Capacity (Engine Only): 9.9 L

-

Fuel System: BYC Type A inline pump

-

Cooling Method: Closed water cooling cycle

-

Speed Regulation: Electronic governor

-

Starting Method: DC24V electric start

-

Intake System: Turbocharged with aftercooler

-

Cycle Type: Four-stroke

-

Load Fluctuation: ±0.25%

-

Power Deviation: ≤ ±5%

Generator Specifications

-

Generator Model: UCI274E

-

Manufacturer: Cummins Generator Technologies (China) Ltd.

-

Capacity: 150 KVA

-

Voltage Options: 400V/230V

-

Type: Brushless, single bearing, rotating magnetic field

-

Excitation System: Self-excited with automatic voltage regulation

-

Winding Structure: 2/3 pitch

-

Phase Configuration: Three-phase, four-wire

-

Insulation Class: H

-

Power Factor: 0.8 lagging

-

Connection: Star (Y)

-

Protection Level: IP23

-

Interference Standards: Meets BS800, VDE, and other international standards

Environmental & Operating Requirements

-

Altitude: ≤ 1000 m

-

Fuel: 0# light diesel

-

Atmospheric Pressure: ≥ 89.9 kPa

-

Oil Standard: CF grade / 15W-40

-

Intake Temperature: ≤ 40°C

-

Water Quality (pH): 6.5 – 8.0

-

Relative Humidity: ≤ 60%

-

Surface Mildew Level: Complies with GB/T2423.16 (Class 2)

-

Seismic Resistance: Horizontal acceleration 0.2g, Vertical acceleration 0.1g

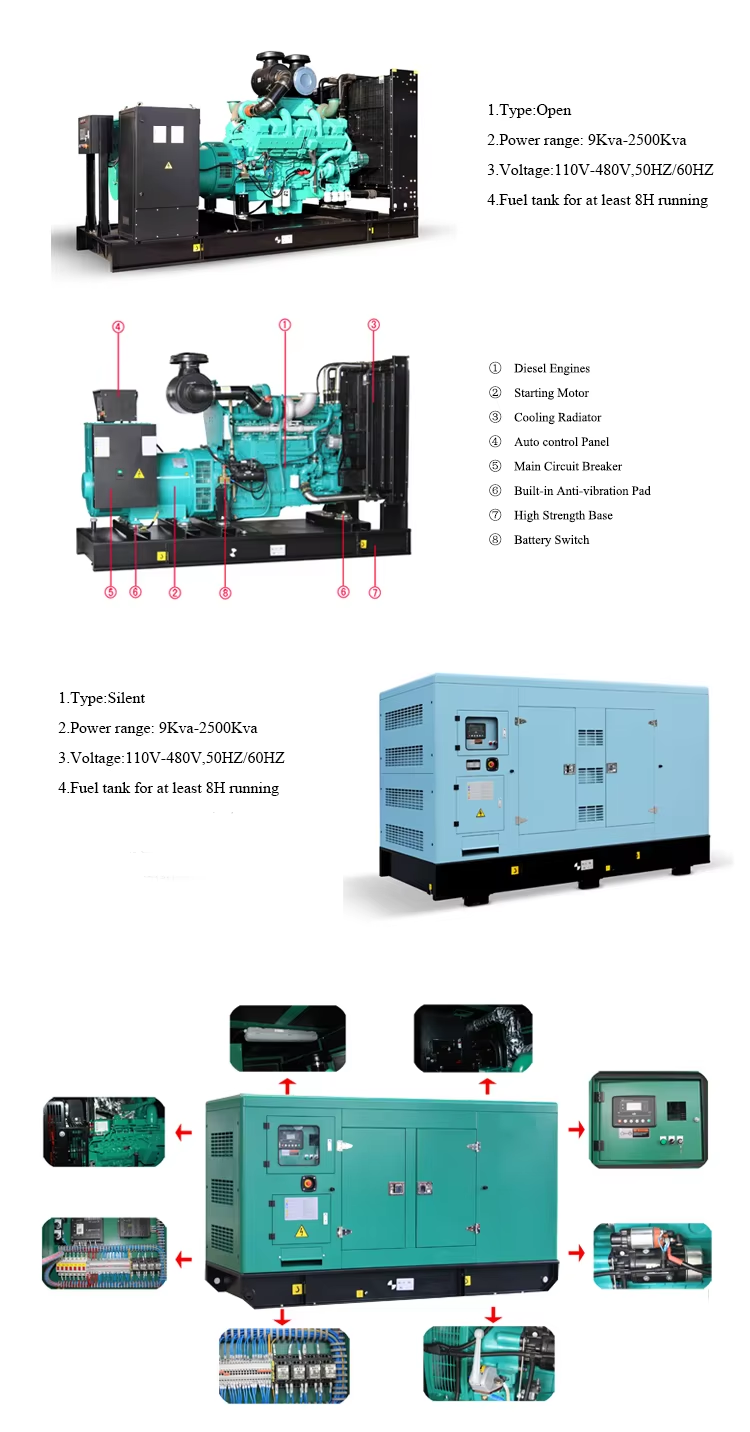

Standard Configurations & Accessories

Engine Components

-

High-performance engine with diesel, air, and oil filters

-

Integrated charger and DC24V starter motor

Generator Components

-

Stamford UCI274E generator

-

Air circuit breaker

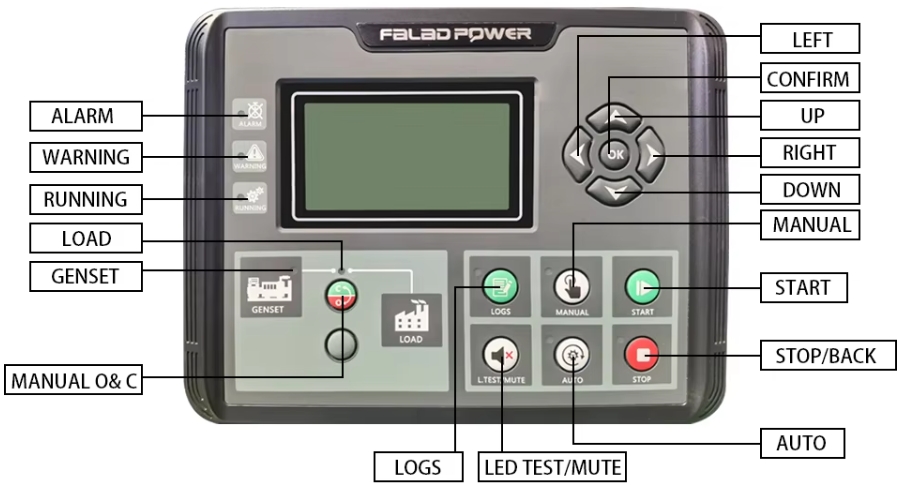

Control & Support Systems

-

LCD digital display controller with electronic governor

-

Steel base with anti-vibration pads

-

Radiator with integrated cooling fan

Additional Accessories

-

Silencer for noise reduction

-

Battery, battery cables, and oil supply

-

Anti-vibration mounts for enhanced stability

Certifications & Standards

The 120kW Cummins Diesel Generator complies with a wide range of international and national standards, including:

-

Military Standard: GJB 5785-2006

-

National Standard: GB/T2820-2002

-

Communication Standard: YD/T502-2007

-

Industry Standard: JB/T10303-2001

-

Environmental Certifications: Noise & Vibration Class A / Emissions Class A

-

TE Quality Certification: YD/T502-2007

Warranty & Service Support

Cummins stands by its product quality by offering a comprehensive warranty of 1 year or 1000 running hours, whichever comes first. Our nationwide network of professional service centers provides 24/7 technical support and after-sales service, ensuring that your generator is always ready when you need it most.

Conclusion

The 120kW Cummins Diesel Generator is an ideal solution for applications requiring dependable power under severe conditions. With its advanced engineering, reliable performance, and robust support network, it delivers peace of mind and operational excellence. Whether for backup power or continuous operation, this generator is built to exceed expectations.

Product configuration and details

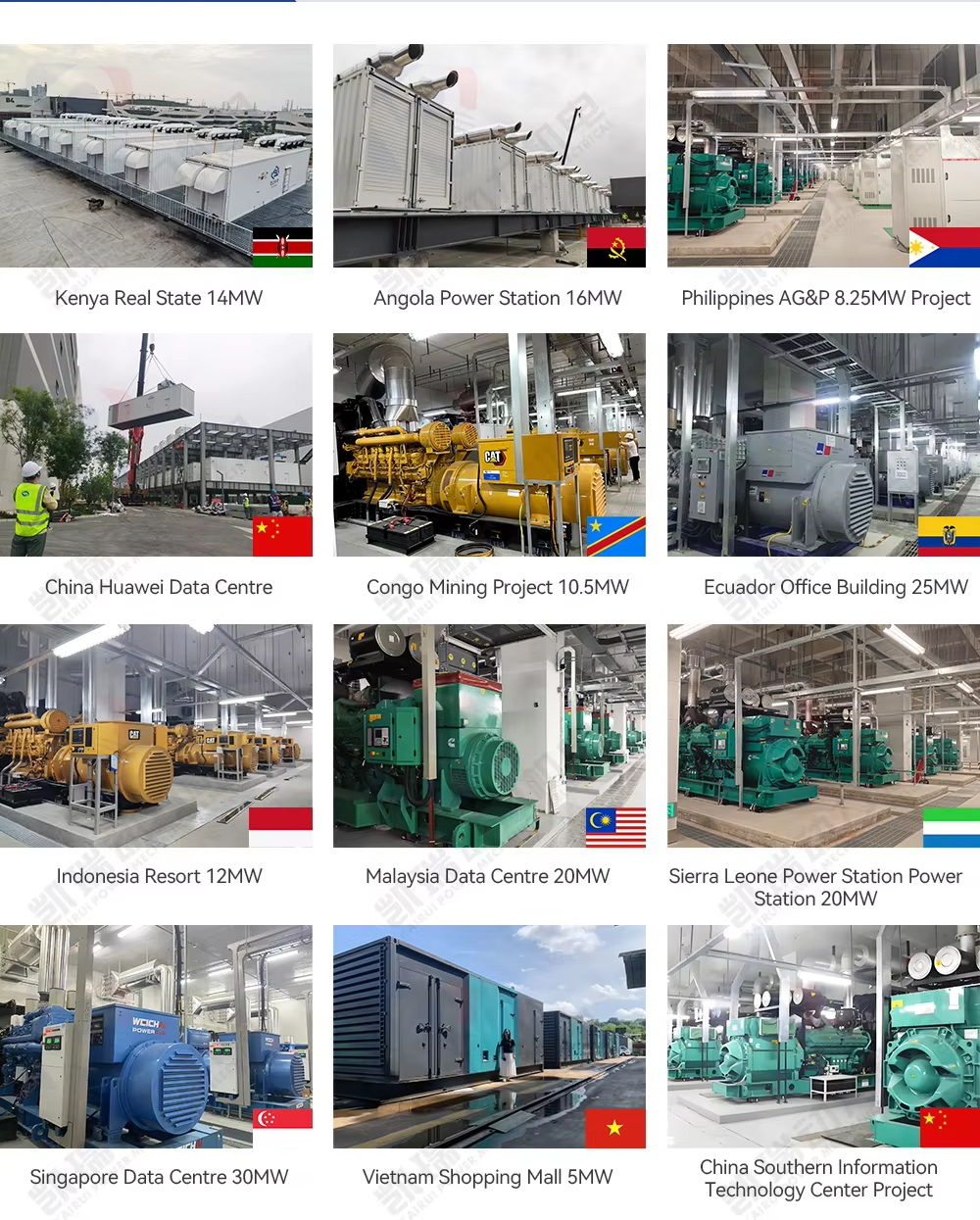

Successful Project

Logistics Packaging

Get Your 60KW Cummins Diesel Generator Today!

Whether you need a dependable backup power source for your business or a primary power solution for industrial applications, the 120KW Cummins Diesel Generator is a top-tier choice. Contact us today for pricing, availability, and customization options!

📧 Email: [ gmail@xn-gen.com]

📞 Phone: [+86 15216161715]

🌐 Website: [xn-gen.com]

XN-GEN.COM

XN-GEN.COM