Reliable & Efficient Diesel Welding Generator

The XN-10SWDG Silent Welder Diesel Generator is a powerful, stable, and easy-to-use welding generator designed for professionals. Featuring a four-stroke, water-cooled, V-twin diesel engine, this 10kW silent generator ensures efficient power delivery while maintaining low noise levels. With a welding current range of 0-250A, it is ideal for a wide range of welding applications, offering both reliability and mobility.

Key Features

1. Powerful & Consistent Performance

- Equipped with a high-quality AVR Brush Copper Alternator for stable power output.

- Supports both 50Hz and 60Hz frequencies, ensuring compatibility with various operational needs.

- Delivers 9kW rated power, capable of handling demanding welding tasks with ease.

2. Advanced Welding Capabilities

- Adjustable welding current: 20Un – 250Un

- Stable welding voltage: 75V – 85V

- Compatible with electrode diameters ranging from 2.5mm to 6.0mm.

3. Durable & Long-Lasting

- Features a rugged diesel engine (EV80) with 0.794L displacement.

- 30L fuel tank ensures a long 7.5-hour continuous runtime.

- Low oil pressure and high water temperature shutdown protect the engine, ensuring durability and safety.

4. User-Friendly Digital Control Panel

- Electric start for effortless operation.

- NANO digital display panel provides real-time monitoring of total running hours and welding generator history.

- Built-in safety system includes overspeed and underspeed shutdown to prevent engine damage.

5. Low-Noise Silent Operation

- Designed with soundproof insulation, the generator operates at only 75 dB at 7 meters, making it suitable for noise-sensitive environments.

Technical Specifications

| Specification |

50Hz |

60Hz |

| Potenza nominale (kW) |

10 |

10 |

| Tensione nominale (V) |

115/230 |

120/240 |

| Corrente nominale (Un) |

78.3/39.1 |

75/37.5 |

| Welding Voltage (V) |

75-85 |

75-85 |

| Welding Current (Un) |

250 |

250 |

| Working Voltage (V) |

35 |

35 |

| Current Adjustment (Un) |

20-250 |

20-250 |

| Electrode Diameter (millimetro) |

2.5-6.0 |

2.5-6.0 |

| Fuel Tank Capacity (L) |

30 |

30 |

| Runtime (orario) |

7.5 |

7.5 |

| Noise Level (dB at 7m) |

75 |

75 |

| Modello di motore |

EV80 |

EV80 |

| Spostamento (L) |

0.794 |

0.794 |

| Engine Power (kW) |

12 |

13.2 |

| Net Weight (Kg) |

318 |

318 |

| Dimensioni (millimetro) |

1360x650x980 |

1360x650x980 |

Why Choose the XN-10SWDG Silent Welder Diesel Generator?

✅ Professional-Grade Performance – Designed for industrial welding and power applications.

✅ Reliable Diesel Engine – Long lifespan with built-in protection features.

✅ Quiet Operation – Low noise levels for a comfortable work environment.

✅ Easy to Use & Maintain – Digital controls, electric start, and self-protection functions.

✅ Extended Runtime – Large fuel tank allows continuous operation for extended periods.

Advanced LCD Digital Display with Smart Protection Features

- Monitors key parameters such as generator voltage, corrente, power, frequenza, temperature, and operating time.

- Automatically shuts down the generator if any parameter exceeds safety limits.

ATS System & Remote Control

- The Automatic Transfer Switch (ATS) system enables the generator to start automatically during a power outage and shut down when power is restored—no manual intervention required.

- Remote control functionality allows users to start and stop the generator from a distance of 50-100 meters.

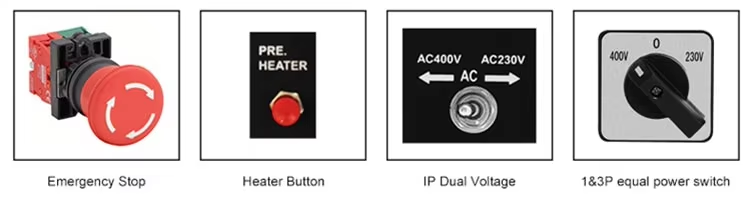

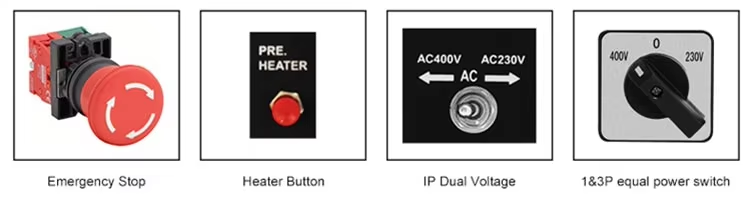

Enhanced Safety & Convenience Features

- Emergency stop function for increased safety.

- Pre-heating system ensures reliable startup in cold weather conditions.

- Voltage selection system provides equivalent power output for both single-phase and three-phase voltage options.

Order Yours Today!

The XN-10SWDG Silent Welder Diesel Generator is the perfect solution for welders who need reliable, silent, and efficient power. Whether you are working on construction sites, industrial applications, or remote projects, this generator is built to handle the toughest jobs with ease.

🔹 Contact us now to learn more about pricing and availability!

- 📧 E-mail: [ gmail@xn-gen.com]

- 📞 Telefono: [+86 15216161715]

- 🌐 Visit Our Website: XN-GEN.COM

Manutenzione e assistenza del generatore

Presso XN-GEN, Offriamo contratti di manutenzione a lungo termine per fornire, di alta qualità, e un servizio senza problemi per i nostri clienti. I nostri servizi di manutenzione garantiscono le prestazioni ottimali e la longevità del vostro gruppo elettrogeno. Di seguito sono riportate le linee guida generali per le procedure di manutenzione (Si prega di notare che le azioni specifiche possono variare in base al modello e allo stato operativo di ciascun gruppo elettrogeno).

Manutenzione ordinaria

Ispezioni e manutenzione regolari sono fondamentali per garantire l'affidabilità del generatore. I seguenti controlli devono essere eseguiti regolarmente:

- Ispezionare tutti i componenti rotanti e serrare eventuali bulloni allentati.

- Controllare il livello dell'olio nel carter e rabboccare l'olio se necessario.

- Monitorare i livelli di carburante nel serbatoio.

- Controllare il livello del liquido di raffreddamento nel radiatore.

- Esaminare le condutture del carburante e dell'acqua per verificare la presenza di eventuali perdite o collegamenti allentati.

- Garantire i sistemi di aspirazione e scarico, insieme alle guarnizioni del cilindro, siano adeguatamente sigillati.

- Pulire eventuali macchie d'olio o accumuli di polvere sul generatore per mantenere in ordine la sala macchine.

Piano di manutenzione per i generatori di riserva

(Consigliato per generatori di riserva utilizzati nelle comunità residenziali, edifici commerciali, Ospedali, Strutture governative, Attrazioni turistiche, fabbriche, e altri luoghi in cui le interruzioni di corrente sono rare.)

Manutenzione professionale (Ogni sei mesi o annualmente)

Oltre alla manutenzione ordinaria, Un servizio completo dovrebbe essere eseguito ogni sei mesi o una volta all'anno:

- Effettuare un'ispezione approfondita del carburante, elettrico, raffreddamento, e sistemi di lubrificazione per garantire il corretto funzionamento.

- Eseguire un'esecuzione del test a vuoto per 5-10 minuti per lubrificare il sistema. Valuta le prestazioni del generatore utilizzando l'udito, visivo, e controlli olfattivi.

- Sostituire i filtri dei consumabili, compresa l'aria, diesel, olio, Acqua, e separatori carburante-acqua.

- Svuotare e sostituire il liquido di raffreddamento, garantire il corretto funzionamento del radiatore.

- Controllare e rabboccare l'elettrolito della batteria o l'acqua distillata secondo necessità.

- Dopo aver completato la manutenzione, Effettuare un'ispezione finale e pulire il gruppo elettrogeno.

- Esegui un altro 5-10 test a vuoto minuto, Registrare i parametri delle prestazioni, e fornire raccomandazioni di ottimizzazione prima dell'accettazione da parte del cliente.

Piano di manutenzione per generatori a funzionamento continuo

(Consigliato per generatori in cantiere, fabbriche spesso soggette a interruzioni di corrente, aree con capacità del trasformatore insufficiente, Siti di prova del progetto, o luoghi senza accesso alla rete principale.)

Livello 1 Manutenzione (Ogni 50-80 Orario)

Ciò include tutte le attività di manutenzione ordinaria e:

- Pulire il filtro dell'aria e sostituirlo se necessario.

- Sostituire il filtro del gasolio, filtro dell'aria, e filtro dell'acqua.

- Ispezionare la tensione della cinghia di trasmissione e regolarla se necessario.

- Lubrificare tutti gli ingrassatori e i componenti mobili.

- Sostituire il refrigerante per mantenere prestazioni di raffreddamento efficaci.

Livello 2 Manutenzione (Ogni 250-300 Orario)

Include il livello 1 Attività di manutenzione, con controlli aggiuntivi:

- Pulizia e ispezione dei pistoni, spinotti pistone, canne cilindro, fasce elastiche, e cuscinetti di biella per usura.

- Esaminare il cuscinetto principale per eventuali segni di allentamento o usura anomala.

- Rimuovere incrostazioni e sedimenti dal sistema di raffreddamento per garantire una corretta dissipazione del calore.

- Eliminare i depositi carboniosi dalla camera di combustione e dai passaggi di aspirazione/scarico.

- Ispezione e regolazione dei giochi delle valvole, sedi valvole, aste di spinta, e bilancieri.

- Pulire i rotori del turbocompressore e controllare l'usura dei cuscinetti e delle giranti, sostituzione se necessario.

- Serrare o sostituire eventuali bulloni allentati o danneggiati nell'accoppiamento generatore-motore diesel.

Livello 3 Manutenzione (Ogni 500-1000 Orario)

Include il livello 1 e Livello 2 Attività di manutenzione, insieme a servizi aggiuntivi:

- Controllare e regolare la fasatura dell'iniezione del carburante.

- Pulire il serbatoio del carburante per rimuovere i contaminanti.

- Pulire la coppa dell'olio per evitare l'accumulo di morchie.

- Ispezionare e testare gli iniettori di carburante per un'atomizzazione ottimale.

Seguendo questo piano di manutenzione strutturato, I proprietari dei generatori possono garantire prestazioni costanti, maggiore durata, e riduzione del rischio di guasti imprevisti. Il nostro team di esperti di XN-GEN si dedica a fornire un servizio di qualità superiore per mantenere l'alimentazione affidabile in ogni momento.

Per maggiori informazioni o per programmare la manutenzione, Contattaci oggi stesso!

1. Sei una fabbrica o una società commerciale?

Siamo una fabbrica specializzata nella produzione di vari tipi di gruppi elettrogeni. Il nostro impianto di produzione garantisce una produzione di alta qualità e un rigoroso controllo di qualità.

2. Quali sono i vostri mercati principali?

I nostri prodotti sono ampiamente esportati in Sud America, il Medio Oriente, Sud-est asiatico, e l'Africa, Soddisfare le diverse esigenze di alimentazione in diversi settori.

3. Come garantire la qualità del prodotto?

Implementiamo rigorose misure di controllo della qualità in ogni fase della produzione. Prima della consegna, Tutti i gruppi elettrogeni vengono sottoposti a test di carico all'interno di un container per garantire prestazioni e affidabilità ottimali.

4. Qual è la vostra politica di garanzia?

I nostri prodotti sono coperti da una garanzia standard del settore di un anno o 1,000 Orari di apertura (a seconda dell'evento che si verifica per primo). Forniamo anche supporto tecnico e servizi di ricambi.

5. Possiamo personalizzare il generatore con il nostro logo o design?

Sì! Offriamo marchi personalizzati per loghi e design autorizzati, Permettendoti di personalizzare l'aspetto del generatore in base alle tue esigenze aziendali.

6. Quali sono i tempi di consegna?

I nostri tempi standard di produzione e consegna sono entro 15 giorni lavorativi, a seconda della quantità dell'ordine e dei requisiti di personalizzazione.

7. Come posso diventare il vostro distributore?

Accogliamo con favore le partnership con aziende che dispongono di forti risorse di marketing e capacità di assistenza post-vendita. Se soddisfi questi criteri e sei interessato a collaborare, Non esitate a contattarci per ulteriori discussioni.

8. Fornite assistenza post-vendita?

Sì! Offriamo assistenza tecnica, fornitura di pezzi di ricambio, e risoluzione dei problemi da remoto per garantire un funzionamento senza interruzioni dei nostri gruppi elettrogeni.

9: Quali sono i termini di pagamento che puoi accettare?

- Un: T/T, 30% depositare, 70% verrà pagato prima della consegna;

- o T/, 30% depositare, 70% L/C a vista;

- o 100% L/C a vista;

XN-GEN.COM

XN-GEN.COM