Overview

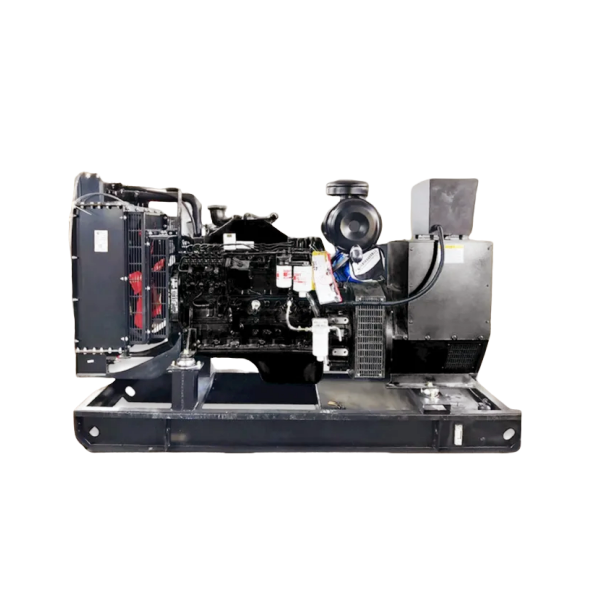

Experience superior power and reliability with our 100KW Cummins Diesel Generator. Engineered with cutting-edge technology and designed to meet the highest industry standards, this generator is a prime solution for industrial, commercial, and emergency power applications. Powered by the renowned Cummins 6BTA5.9-G2 diesel engine and paired with a Stamford UCI274D generator, this unit delivers dependable performance even under the most demanding conditions.

Key Features

-

Robust Power Performance:

-

Rated Power: 100KW (with a common operating power of 90KW)

-

Engine Model: Cummins 6BTA5.9-G2

-

Generator Model: Stamford UCI274D

-

Advanced Engineering:

-

High-pressure common rail and turbocharging technology for improved fuel efficiency and reduced emissions

-

Integrated design minimizes component count by approximately 40%, reducing the risk of leaks and maintenance needs

-

Durability and Reliability:

-

Suitable for continuous, standby, and peak load applications

-

Built to withstand harsh environments with robust construction and superior vibration dampening

-

Compliance and Certification:

-

Meets ISO8528-2005 and GB/T2820-2009 standards for reciprocating internal combustion engine-driven AC generators

-

Certified to ISO9001/ISO9002 manufacturing standards

-

Guaranteed for 1 year or 1,000 running hours across all major components including engine, generator, and control system

Technical Specifications

Generator Parameters

-

Unit Model: XN-100CDG

-

Alternate Power Rating: 100KW (standby), 90KW (continuous)

-

Power Factor: 0.8 (lagging)

-

Output Voltage: 400V/230V

-

Frequency: 50Hz

-

KVA Rating: 130KVA

-

Voltage Regulation:

-

Steady-State: ±1%

-

Transient: -15%/+20%

-

Response Time: Voltage stabilizes within 3 seconds

-

Waveform Distortion: ≤8% THD

-

Dimensions: 2250 x 800 x 1325 mm

-

Weight: 1160 kg

Engine Parameters

-

Tatak: Mga Cummins

-

Engine Model: 6BTA5.9-G2

-

Configuration: Inline 6-cylinder

-

Displacement: 5.9 Liters

-

Compression Ratio: 17.5:1

-

Bore & Stroke: 102 x 120 mm

-

Fuel Consumption: Approximately 211 g/kW.h

-

Oil Capacity: 16.4 Liters

-

Cooling Capacity: 9.9 Liters (engine only)

-

Fuel System: PB inline pump

-

Cooling System: Closed water-cooling circuit

-

Starting System: DC24V electric starter

-

Operating Speed: 1500 r/min

Environmental and Operational Requirements

-

Altitude: Up to 1000 m

-

Ambient Temperature: Intake air temperature up to 40°C

-

Atmospheric Pressure: ≥89.9 kPa

-

Fuel Standard: 0# light diesel

-

Oil Standard: CF-grade / 15W-40

-

Relative Humidity: ≤60%

-

Water Quality (pH): 6.5 – 8

-

Surface Mold Level: ≤GB/T2423.16/2 level

-

Seismic Resistance: Horizontal acceleration 0.2g, Vertical acceleration 0.1g

Standard Configuration & Accessories

-

Engine Assembly:

-

Cummins diesel engine

-

Diesel, air, and oil filters

-

Charging system and electric starter

-

Generator Assembly:

-

Stamford generator unit

-

Integrated air switch

-

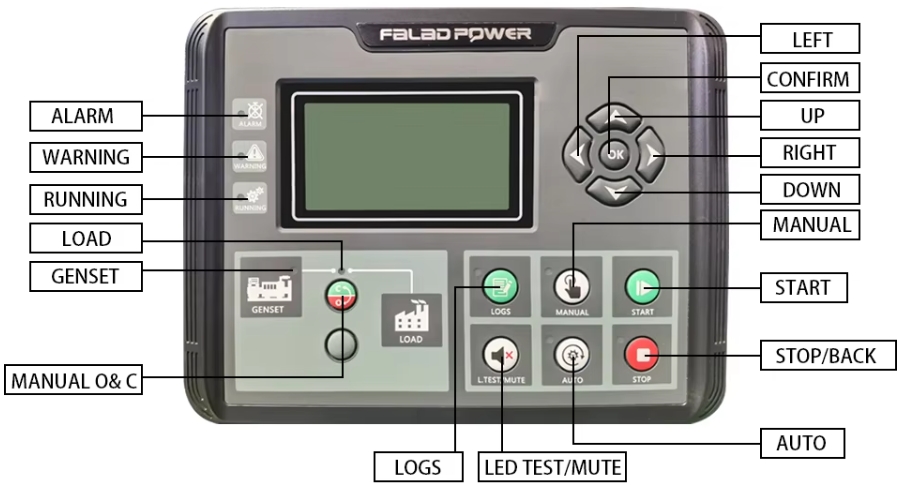

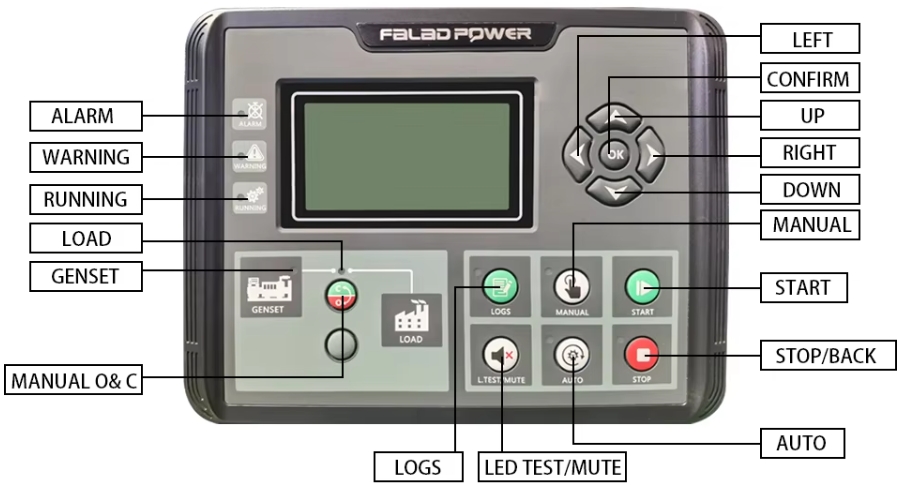

Control System:

-

Additional Components:

-

Optional Accessories:

Quality Assurance and Support

Mga aplikasyon

The 100KW Cummins Diesel Generator is ideal for:

-

Industrial Sites: Construction, mining, and manufacturing facilities requiring uninterrupted power

-

Commercial Establishments: Retail, data centers, and hospitals needing backup power solutions

-

Emergency and Remote Locations: Reliable power supply for remote work sites and emergency backup systems

Conclusion

Our 100KW Cummins Diesel Generator combines industry-leading engine technology with a robust generator system, ensuring high performance, reliability, and efficiency. It is designed to meet the demands of modern power applications while complying with international standards. Invest in dependable power with our expertly engineered generator solution.

Product configuration and details

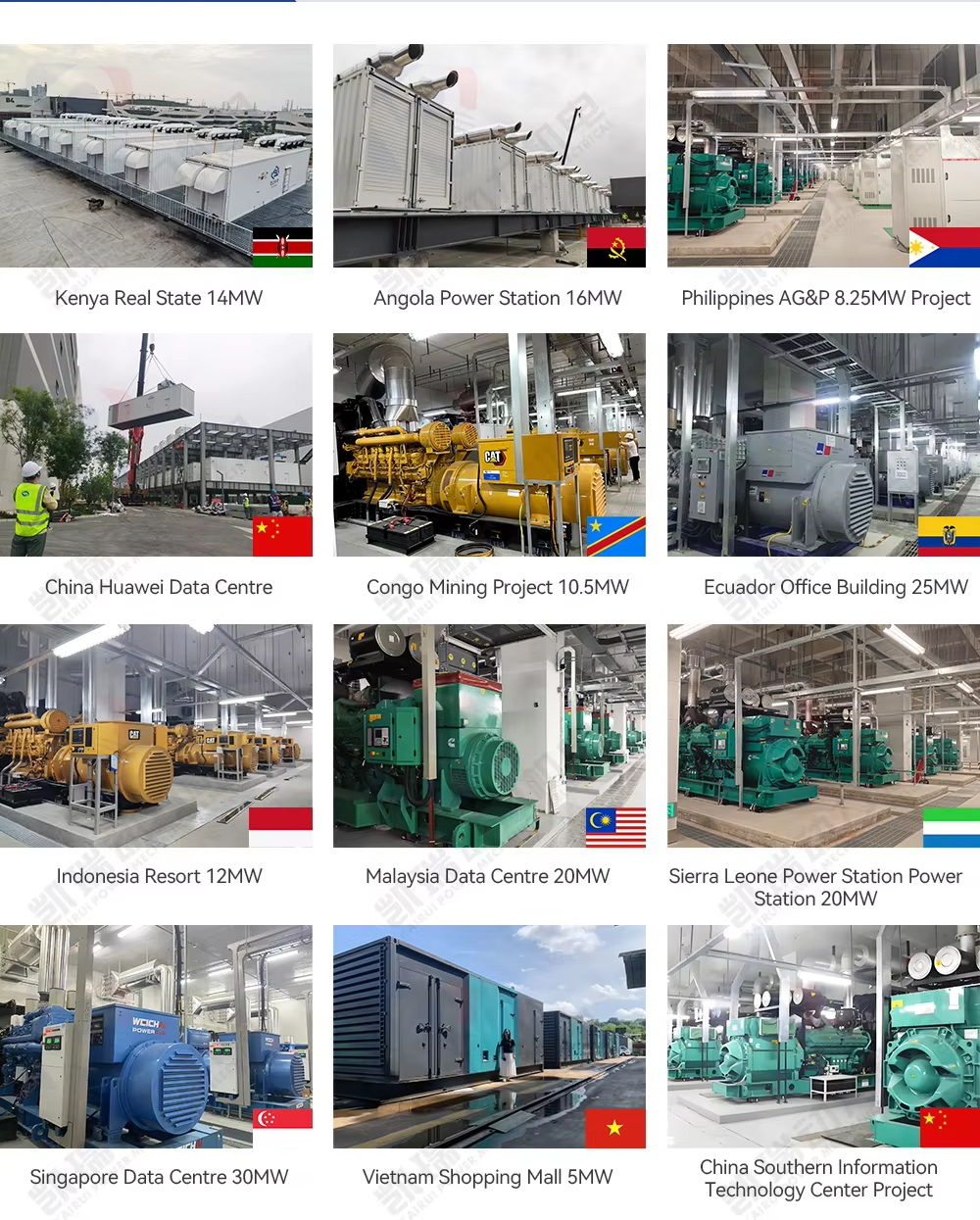

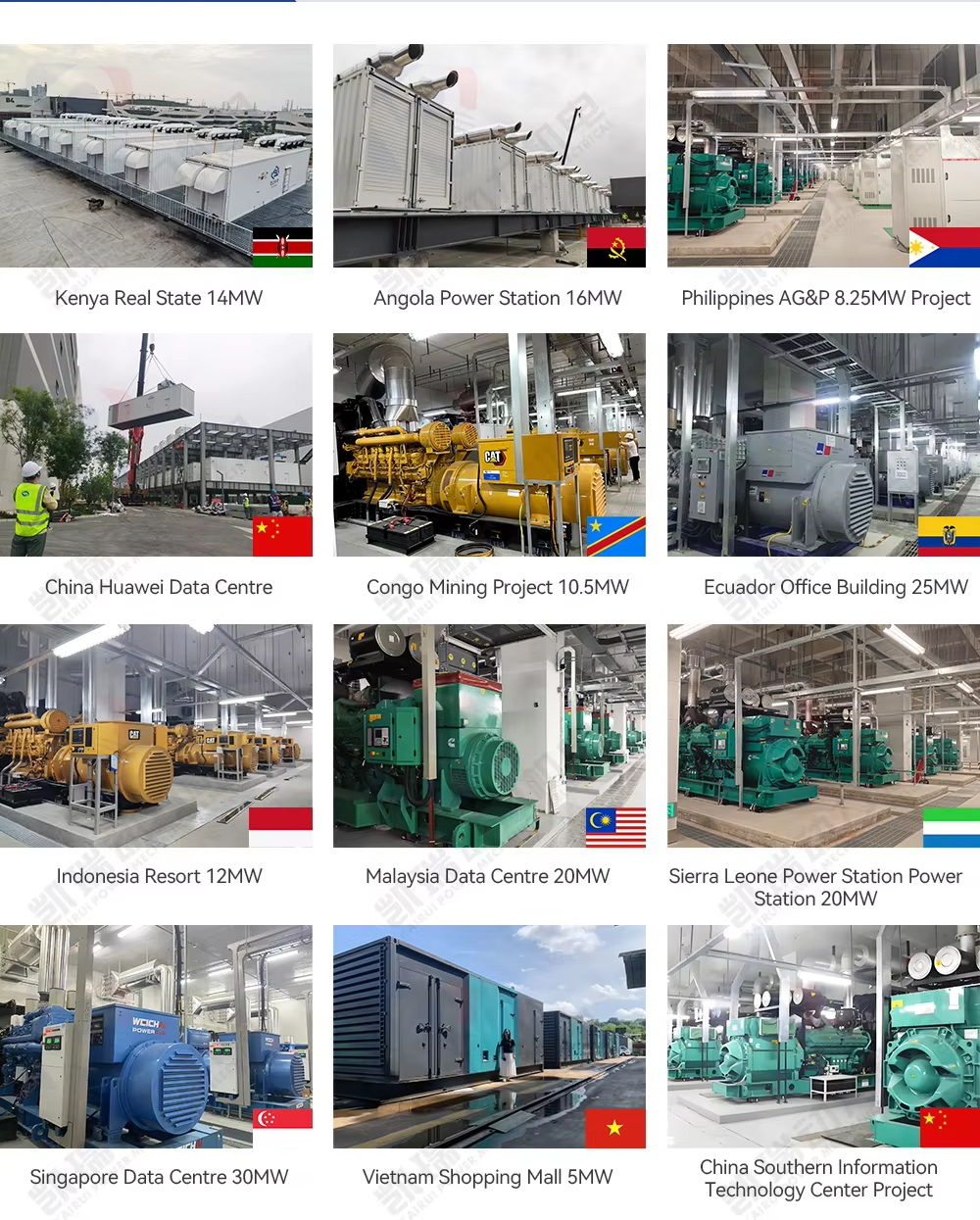

Successful Project

Logistics Packaging

Get Your 60KW Cummins Diesel Generator Today!

Whether you need a dependable backup power source for your business or a primary power solution for industrial applications, the 100KW Cummins Diesel Generator is a top-tier choice. Contact us today for pricing, availability, and customization options!

📧 Email: [ gmail@xn-gen.com]

📞 Phone: [+86 15216161715]

🌐 Website: [xn-gen.com]

Generator Maintenance and Servicing

At XN-GEN, we offer long-term maintenance agreements to provide professional, high-quality, and hassle-free service for our customers. Our maintenance services ensure the optimal performance and longevity of your generator set. Below is a general guideline for maintenance procedures (please note that specific actions may vary based on the model and operational status of each generator set).

Routine Maintenance

Regular inspections and upkeep are crucial to ensuring the reliability of your generator. The following checks should be performed regularly:

- Inspect all rotating components and tighten any loose bolts.

- Check the oil level in the crankcase and add oil if necessary.

- Monitor fuel levels in the tank.

- Inspect the coolant level in the radiator.

- Examine fuel and water pipelines for any leaks or loose connections.

- Ensure the intake and exhaust systems, along with cylinder gaskets, are properly sealed.

- Clean any oil stains or dust accumulation on the generator to maintain a tidy machine room.

Maintenance Plan for Standby Generators

(Recommended for backup generators used in residential communities, commercial buildings, hospitals, government facilities, tourist attractions, factories, and other locations where power outages are rare.)

Professional Maintenance (Every Six Months or Annually)

In addition to routine maintenance, a comprehensive service should be performed every six months or once a year:

- Conduct a thorough inspection of the fuel, electrical, cooling, and lubrication systems to ensure proper functionality.

- Perform a no-load test run for 5-10 minutes to lubricate the system. Assess the generator's performance using auditory, visual, and olfactory checks.

- Replace consumable filters, including air, diesel, oil, water, and fuel-water separators.

- Drain and replace coolant, ensuring proper radiator function.

- Check and replenish the battery electrolyte or distilled water as needed.

- After completing the maintenance, conduct a final inspection and clean the generator set.

- Perform another 5-10 minute no-load test, record performance parameters, and provide optimization recommendations before customer acceptance.

Maintenance Plan for Continuous Operation Generators

(Recommended for generators in construction sites, frequently power-outage-prone factories, areas with insufficient transformer capacity, project testing sites, or locations without access to the main grid.)

Level 1 Maintenance (Every 50-80 Hours)

This includes all routine maintenance tasks plus:

- Clean the air filter and replace it if necessary.

- Replace the diesel filter, air filter, and water filter.

- Inspect the tension of the drive belt and adjust if needed.

- Lubricate all grease fittings and moving components.

- Replace coolant to maintain effective cooling performance.

Level 2 Maintenance (Every 250-300 Hours)

Includes Level 1 maintenance tasks, with additional checks:

- Clean and inspect pistons, piston pins, cylinder liners, piston rings, and connecting rod bearings for wear.

- Examine the main bearing for any signs of looseness or abnormal wear.

- Remove scale and sediment from the cooling system to ensure proper heat dissipation.

- Clear carbon deposits from the combustion chamber and intake/exhaust passages.

- Inspect and adjust valve clearances, valve seats, push rods, and rocker arms.

- Clean turbocharger rotors and check bearings and impellers for wear, replacing if necessary.

- Tighten or replace any loosened or damaged bolts in the generator-diesel engine coupling.

Level 3 Maintenance (Every 500-1000 Hours)

Includes Level 1 and Level 2 maintenance tasks, along with additional services:

- Check and adjust the fuel injection timing.

- Clean the fuel tank to remove contaminants.

- Clean the oil sump to prevent sludge buildup.

- Inspect and test the fuel injectors for optimal atomization.

By following this structured maintenance plan, generator owners can ensure consistent performance, increased lifespan, and reduced risk of unexpected failures. Our expert team at XN-GEN is dedicated to delivering superior service to keep your power supply reliable at all times.

For more information or to schedule maintenance, contact us today!

1. Are you a factory or a trading company?

We are a factory specializing in the production of various types of generator sets. Our manufacturing facility ensures high-quality production and strict quality control.

2. What are your main markets?

Our products are widely exported to South America, the Middle East, Southeast Asia, and Africa, catering to diverse power needs across different industries.

3. How do you ensure product quality?

We implement strict quality control measures at every stage of production. Before delivery, all generator sets undergo load testing inside a shipping container to ensure optimal performance and reliability.

4. What is your warranty policy?

Our products come with an industry-standard warranty of one year or 1,000 operating hours (whichever comes first). We also provide technical support and spare parts services.

5. Can we customize the generator with our logo or design?

Yes! We offer custom branding for authorized logos and designs, allowing you to personalize the generator’s appearance according to your business needs.

6. What is your delivery time?

Our standard production and delivery time is within 15 working days, depending on order quantity and customization requirements.

7. How can I become your distributor?

We welcome partnerships with companies that have strong marketing resources and after-sales service capabilities. If you meet these criteria and are interested in collaborating, feel free to contact us for further discussions.

8. Do you provide after-sales support?

Yes! We offer technical assistance, spare parts supply, and remote troubleshooting to ensure seamless operation of our generator sets.

9: What is the payment terms you can accept?

- A: T/T, 30% deposit, 70% will be paid before delivery;

- or T/, 30% deposit, 70% L/C at sight;

- or 100% L/C at sight;

XN-GEN.COM

XN-GEN.COM