Descripción general del producto

The 550KW Diesel Generator is a high-performance power solution designed to deliver consistent and efficient energy output for various industrial and commercial applications. With a robust build, advanced cooling system, and compliance with international standards, this generator ensures seamless operation even in demanding conditions.

Key Specifications

Grupo electrógeno

- Modelo: XN-550GFS

- Potencia principal: 550KW / 687.5KVA

- Alimentación en espera: 600KW / 750KVA

- Rated Current: 990Un

- Dimensiones (L×W×H): 4450 × 1760 × 2180 milímetro

- Peso: 5650 kg

Diesel Engine

- Modelo: SC27G900D2

- Rated Speed: 1500 RPM

- Engine Power: 602KW / 662KW

- Cylinder Bore × Stroke: 135 × 155 milímetro

- Number of Cylinders: 12

- Desplazamiento: 26.6L

- Relación de compresión: 16:1

- Aspiration: Turbocharged & Air-to-Air Intercooling

- Método de enfriamiento: Closed-Loop Freshwater Cooling

- Exhaust Temperature: 600°C

- Total Coolant Capacity: 48L

- Operating Temperature Range: 82-93°C

- Temperatura máxima del aceite: 103°C

- Lubrication Oil Capacity: 65L

- Consumo de combustible (Clasificada): 110.2 L/h

- Speed Regulation: Electronic (E-Governor)

Alternador

- Marca: XN Synchronous Alternator

- Conformidad: GB755, BS5000, VDE0530, IEC34-1, CSA22.2, AS2359

- Voltaje: 400V / 230V

- Modelo: JXXN-550

- Capacidad nominal: 550KW / 687.5KVA

- Eficacia: 93.70%

- Factor de potencia: 0.8 (Lagging)

- Sistema de excitación: Sin escobillas, Self-Excited

- Voltage Regulation: ±1%

- Fase: 3-Fase

- Protection Rating: IP23

- Clase de aislamiento: H

Sistema de control

- Controller Model: HGM6110

- Display: LED Integrated Instrument Panel

- Monitoring & Protection: Automatic alarms for low oil pressure, high coolant temperature, over-speed, and emergency shutdown.

- Battery Capacity: 2 × 120AH 12V

Características principales & Benefits

✔ Reliable Power Output – Delivers a continuous power supply, making it ideal for critical facilities, industrial plants, and emergency power backup.

✔ High Efficiency – Advanced fuel injection system ensures optimized fuel consumption and reduced operational costs.

✔ Compact Design – Saves up to 20% installation space, allowing for more operational flexibility.

✔ Lightweight Build – 18% lighter than conventional generators, making it easier to transport and install.

✔ Durable Construction – Built with high-quality materials to withstand extreme conditions and prolonged operation.

✔ Advanced Cooling System – Ensures stable engine performance, extending the lifespan of the generator.

✔ Quiet Operation Options – Optional soundproof enclosures are available to reduce noise levels in noise-sensitive environments.

✔ Compliant with International Standards – Meets ISO3046, UL2200, and ULC certification requirements for quality and safety.

Aplicaciones

- Industrial Facilities – Ensures uninterrupted production and operations.

- Data Centers – Provides reliable backup power to prevent downtime.

- Hospitals & Healthcare – Critical power supply for emergency rooms, ICUs, and medical equipment.

- Construction Sites – Ideal for powering tools and heavy machinery.

- Commercial Buildings – Acts as an emergency backup to keep businesses running.

Important Considerations

🔹 Fuel Storage: Ensure adequate fuel supply for extended operation.

🔹 Noise Management: Consider optional noise-reduction enclosures for urban or residential areas.

🔹 Regular Maintenance: Periodic servicing is essential to maintain efficiency and prolong the generator’s lifespan.

Certificaciones & Conformidad

- UL2200 Certified – Meets strict safety and performance standards.

- Optional ULC Certification – Available upon request.

- ISO & IEC Compliant – Built to international quality and reliability standards.

Why Choose Our 550KW Diesel Generator?

Our 550KW Diesel Generator is engineered for reliability, efficiency, and durability. Whether you need a primary power source or a backup generator, this unit ensures your operations continue smoothly, even during power outages. Its high-performance engine, efficient fuel consumption, and advanced monitoring system make it a superior choice for industrial, comercial, and emergency power applications.

Technical drawings:

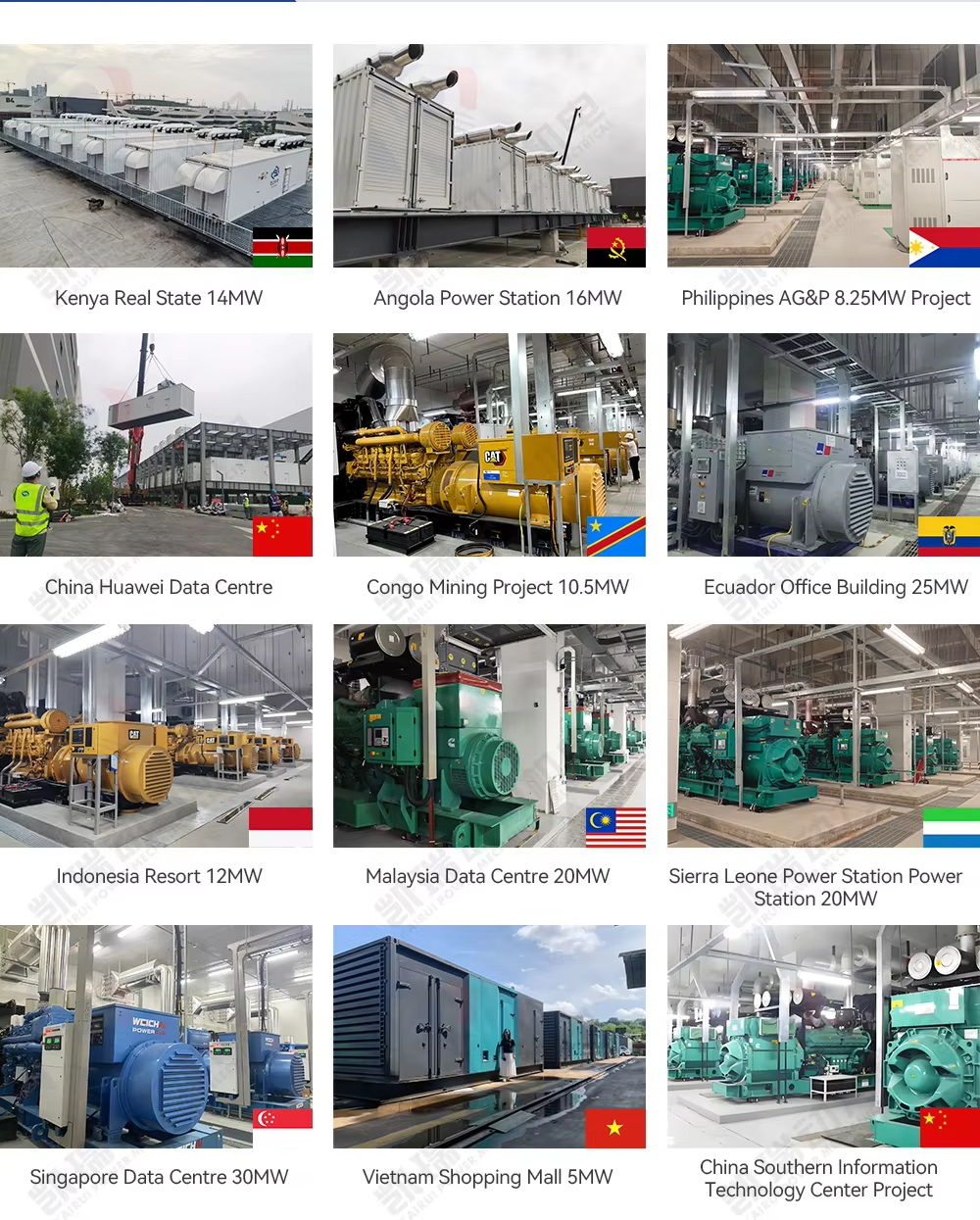

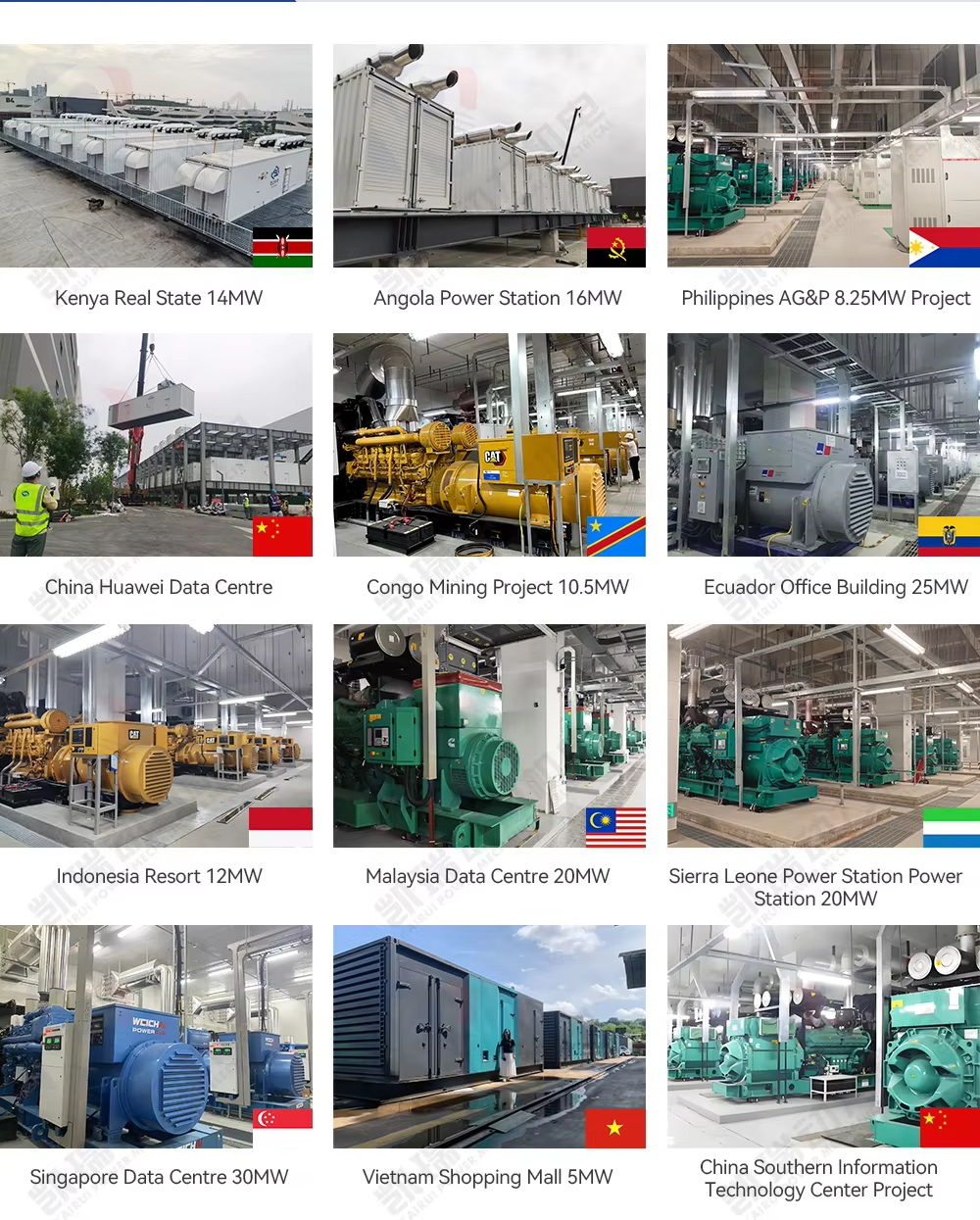

Successful Project

Embalaje Logístico

🚀 Get in Touch Today! Contact us for pricing, Opciones de personalización, and availability.

📧 Correo electrónico: [ gmail@xn-gen.com]

📞 Teléfono: [+86 15216161715]

🌐 Sitio web: [xn-gen.com]

Mantenimiento y servicio de generadores

En XN-GEN, Ofrecemos contratos de mantenimiento a largo plazo para proporcionar servicios profesionales, de alta calidad, y un servicio sin complicaciones para nuestros clientes. Nuestros servicios de mantenimiento garantizan el rendimiento óptimo y la longevidad de su grupo electrógeno. A continuación se muestra una guía general para los procedimientos de mantenimiento (Tenga en cuenta que las acciones específicas pueden variar según el modelo y el estado operativo de cada grupo electrógeno).

Mantenimiento de rutina

Las inspecciones y el mantenimiento regulares son cruciales para garantizar la confiabilidad de su generador. Las siguientes comprobaciones deben realizarse con regularidad:

- Inspeccione todos los componentes giratorios y apriete los pernos sueltos.

- Verifique el nivel de aceite en el cárter y agregue aceite si es necesario.

- Monitoree los niveles de combustible en el tanque.

- Inspeccione el nivel de refrigerante en el radiador.

- Examine las tuberías de combustible y agua en busca de fugas o conexiones sueltas.

- Asegurar los sistemas de admisión y escape, junto con las juntas de los cilindros, están debidamente sellados.

- Limpie cualquier mancha de aceite o acumulación de polvo en el generador para mantener ordenada la sala de máquinas.

Plan de mantenimiento para generadores de reserva

(Recomendado para generadores de respaldo utilizados en comunidades residenciales, Edificios comerciales, Hospitales, Instalaciones gubernamentales, Atracciones turísticas, fábricas, y otros lugares donde los cortes de energía son raros.)

Mantenimiento Profesional (Cada seis meses o anualmente)

Además del mantenimiento rutinario, Un servicio integral debe realizarse cada seis meses o una vez al año:

- Realice una inspección exhaustiva del combustible, eléctrico, enfriamiento, y sistemas de lubricación para garantizar el correcto funcionamiento.

- Realice una ejecución de prueba sin carga para 5-10 minutos para lubricar el sistema. Evalúe el rendimiento del generador mediante sistemas auditivos, visual, y controles olfativos.

- Reemplace los filtros de consumibles, incluido el aire, gasóleo, aceite, Agua, y separadores de agua y combustible.

- Drene y reemplace el refrigerante, Garantizar el correcto funcionamiento del radiador.

- Revise y reponga el electrolito de la batería o el agua destilada según sea necesario.

- Después de completar el mantenimiento, Realice una inspección final y limpie el grupo electrógeno.

- Realizar otro 5-10 Prueba sin carga de minutos, Registrar parámetros de rendimiento, y proporcionar recomendaciones de optimización antes de la aceptación del cliente.

Plan de Mantenimiento de Generadores de Operación Continua

(Recomendado para generadores en obras de construcción, Fábricas propensas a los cortes de energía con frecuencia, Áreas con capacidad de transformador insuficiente, Sitios de prueba de proyectos, o ubicaciones sin acceso a la red principal.)

Nivel 1 Mantenimiento (Cada 50-80 Horas)

Esto incluye todas las tareas de mantenimiento de rutina más:

- Limpie el filtro de aire y reemplácelo si es necesario.

- Reemplace el filtro de diésel, Filtro de aire, y filtro de agua.

- Inspeccione la tensión de la correa de transmisión y ajústela si es necesario.

- Lubrique todos los engrasadores y componentes móviles.

- Reemplace el refrigerante para mantener un rendimiento de enfriamiento efectivo.

Nivel 2 Mantenimiento (Cada 250-300 Horas)

Incluye Nivel 1 Tareas de mantenimiento, con comprobaciones adicionales:

- Limpie e inspeccione los pistones, Pasadores de pistón, camisas de cilindro, Anillos de pistón, y cojinetes de biela para el desgaste.

- Examine el rodamiento principal en busca de signos de holgura o desgaste anormal.

- Elimine las incrustaciones y los sedimentos del sistema de enfriamiento para garantizar una disipación de calor adecuada.

- Limpie los depósitos de carbón de la cámara de combustión y los conductos de admisión/escape.

- Inspeccione y ajuste las holguras de las válvulas, Asientos de válvulas, varillas de empuje, y balancines.

- Limpie los rotores del turbocompresor y compruebe si están desgastados los cojinetes y los impulsores, Reemplazo si es necesario.

- Apriete o reemplace los pernos aflojados o dañados en el acoplamiento del motor diésel y el generador.

Nivel 3 Mantenimiento (Cada 500-1000 Horas)

Incluye Nivel 1 y Nivel 2 Tareas de mantenimiento, junto con servicios adicionales:

- Verifique y ajuste el tiempo de inyección de combustible.

- Limpie el tanque de combustible para eliminar los contaminantes.

- Limpie el cárter de aceite para evitar la acumulación de lodo.

- Inspeccione y pruebe los inyectores de combustible para una atomización óptima.

Siguiendo este plan de mantenimiento estructurado, Los propietarios de generadores pueden garantizar un rendimiento constante, Aumento de la vida útil, y reducción del riesgo de fallos inesperados. Nuestro equipo de expertos en XN-GEN está dedicado a brindar un servicio superior para mantener su fuente de alimentación confiable en todo momento.

Para obtener más información o para programar el mantenimiento, Póngase en contacto con nosotros hoy mismo!

1. ¿Es usted una fábrica o una empresa comercial??

Somos una fábrica especializada en la producción de varios tipos de grupos electrógenos. Nuestra planta de fabricación garantiza una producción de alta calidad y un estricto control de calidad.

2. ¿Cuáles son sus principales mercados??

Nuestros productos se exportan ampliamente a América del Sur, Oriente Medio, Sudeste Asiático, y África, Satisfacemos diversas necesidades de energía en diferentes industrias.

3. ¿Cómo se garantiza la calidad del producto??

Implementamos estrictas medidas de control de calidad en cada etapa de la producción. Antes de la entrega, Todos los grupos electrógenos se someten a pruebas de carga dentro de un contenedor de envío para garantizar un rendimiento y una fiabilidad óptimos.

4. ¿Cuál es su política de garantía??

Nuestros productos vienen con una garantía estándar de la industria de un año o 1,000 Horario de atención (lo que ocurra primero). También brindamos soporte técnico y servicios de repuestos.

5. ¿Podemos personalizar el generador con nuestro logotipo o diseño??

Sí! Ofrecemos marcas personalizadas para logotipos y diseños autorizados, lo que le permite personalizar la apariencia del generador de acuerdo con las necesidades de su negocio.

6. ¿Cuál es su tiempo de entrega??

Nuestro tiempo estándar de producción y entrega está dentro de 15 Días laborables, Dependiendo de la cantidad del pedido y los requisitos de personalización.

7. ¿Cómo puedo convertirme en su distribuidor??

Damos la bienvenida a las asociaciones con empresas que tienen sólidos recursos de marketing y capacidades de servicio posventa. Si cumples con estos criterios y estás interesado en colaborar, No dude en ponerse en contacto con nosotros para obtener más información.

8. ¿Proporcionan soporte postventa??

Sí! Ofrecemos asistencia técnica, Suministro de piezas de repuesto, y resolución remota de problemas para garantizar el funcionamiento sin problemas de nuestros grupos electrógenos.

9: ¿Cuáles son las condiciones de pago que puede aceptar??

- Un: T/T, 30% depósito, 70% se pagará antes de la entrega;

- o T/, 30% depósito, 70% L/C a la vista;

- o 100% L/C a la vista;

XN-GEN.COM

XN-GEN.COM