Engineered for durability and optimized performance, this generator is ideal for both standby and continuous power applications. It features a robust Cummins 6CTA8.3-G2 diesel engine paired with a high-performance Stamford UCI274G1 generator—delivering exceptional fuel economy, low operating noise, and superior cold-start capability.

Product Overview

The 160KW Cummins Diesel Generator is designed to meet the demands of today’s power-critical environments. With integrated control systems and a compact design, this generator offers:

-

Dual Frequency Capability: Seamlessly switch between 50Hz and 60Hz operation.

-

Optimized Power Output: Delivers a standby power of 160kW and a common load of 145kW.

-

Robust and Reliable: Proven engine and generator combination ensures stable performance even under heavy loads.

-

Enhanced Efficiency: Innovative design reduces the number of parts by nearly 25%, lowering maintenance costs and failure rates.

Βασικά χαρακτηριστικά

-

Advanced Engineering: Incorporates state-of-the-art Cummins diesel engine technology with an integrated Stamford generator.

-

Fuel System Excellence: Equipped with a Bosch inline fuel pump for higher fuel injection pressure, ensuring optimal combustion and stronger power output.

-

Turbocharged Performance: Features a Holset turbocharger with an integrated bypass valve for improved low-speed response and enhanced performance.

-

Compact Integrated Design: Uniform mechanical and electronic control interfaces simplify installation and maintenance.

-

Quiet & Clean Operation: Engineered for low noise levels and reduced emissions, meeting strict environmental standards.

Τεχνικές προδιαγραφές

General Specifications

- Υπόδειγμα:XN-160CDG

- Ισχύς αναμονής: 160kW

- Common Load Power: 145kW

- Operating Frequency: 50Hz (switchable to 60Hz)

- Unit Dimensions: 2400 × 840 × 1345 χιλ.

- Unit Weight: 1700 κιλά

- Fuel Consumption: Approximately 210 g/kW·h

Engine Specifications

-

Μάρκα: Κάμμινς

-

Υπόδειγμα: 6CTA8.3-G2

-

Ισχύς αναμονής: 180kW

-

Ονομαστική ισχύς: 163kW

-

Configuration: 6-cylinder, inline

-

Compression Ratio: 17.0:1

-

Διάμετρος x Εγκεφαλικό επεισόδιο: 114 × 135 χιλ.

-

Εκτόπισμα: 8.3 L

-

Χωρητικότητα λαδιού: 23.8 L

-

Coolant Capacity: 12.3 L (engine only)

-

Σύστημα καυσίμου: PB inline pump

-

Cooling: Closed-loop water cooling

-

Σύστημα εκκίνησης: DC24V electric start

-

Intake: Turbocharged with water/air cooling

Generator Specifications

-

Μάρκα: Stamford

-

Υπόδειγμα: UCI274G1

-

Apparent Power: 175KVA

-

Voltage: 400V/230V

-

Φάση: Three-phase, four-wire

-

Excitation System: Self-excited with automatic voltage regulation

-

Winding Structure: 2/3 pitch

-

Συντελεστής ισχύος: COSΦ = 0.8 lagging

-

Protection Level: ΙΡ23

Electrical Regulation & Εκτέλεση

-

Transient Voltage Regulation: ≤ -15% / +20%

-

Steady-State Voltage Regulation: ±1% (voltage stabilization within 3 seconds)

-

Frequency Regulation:

-

Voltage Distortion: ≤8%

-

Voltage and Frequency Fluctuation: Minimal, ensuring stable operation under load

Standard Equipment & Configuration

-

Engine Package:

-

Diesel engine with integrated filters (ντίζελ, air, and oil)

-

Charging system and starter motor

-

Generator Package:

-

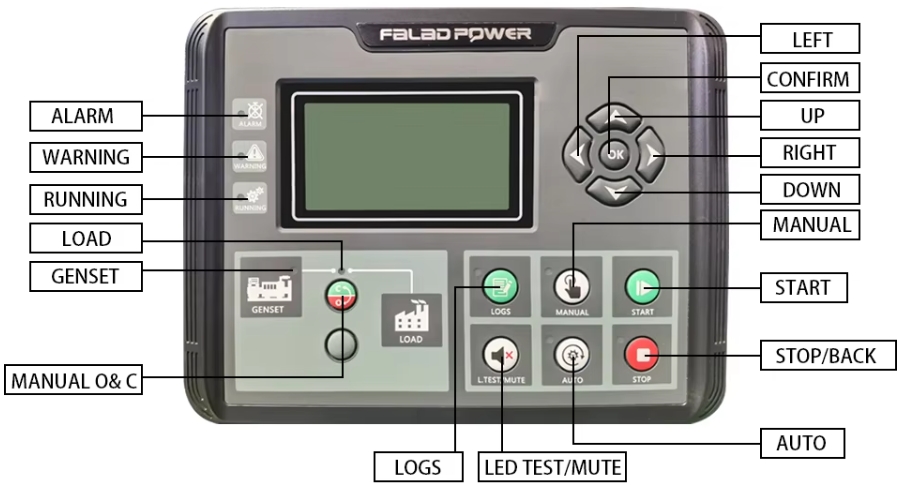

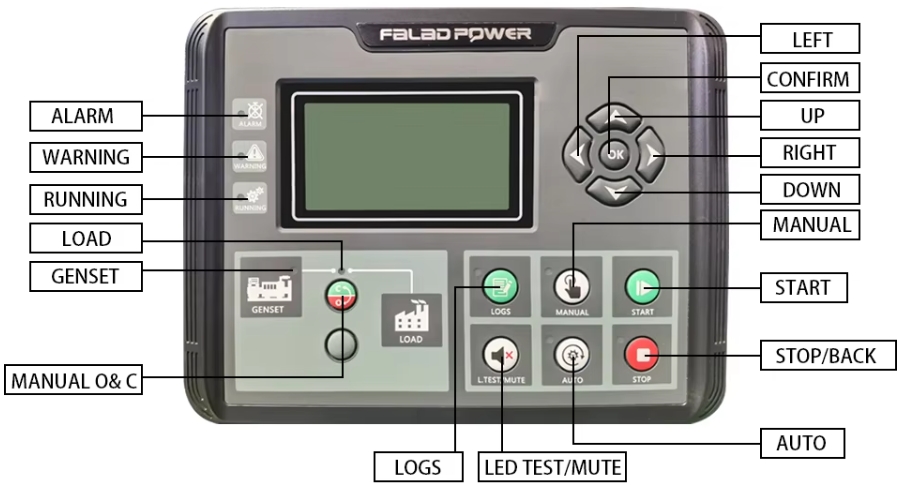

Control System:

-

Auxiliary Components:

-

Water radiator

-

Durable steel base with vibration isolators

-

Exhaust silencers, batteries, and necessary wiring

-

Πιστοποιήσεις:

-

Meets ISO8528-2005 and GB/T2820-2009 standards

-

Manufactured under ISO9001/ISO9002 quality systems

-

Backed by a 1-year or 1000-hour warranty covering the complete unit

Environmental & Συνθήκες λειτουργίας

-

Ύψος: Up to 1000 meters

-

Fuel Standard: 0# light diesel

-

Ambient Air Pressure: ≥89.9 kPa

-

Engine Oil Grade: CF / 15W-40

-

Intake Temperature: Up to 40°C

-

Water Quality: pH 6.5 to 8

-

Relative Humidity: ≤60%

-

Corrosion Resistance: Designed to minimize surface mold per GB/T2423.16 standards

-

Seismic Resistance: Withstands horizontal acceleration of 0.2g and vertical acceleration of 0.1g

Πιστοποιήσεις & Συμμόρφωση

The 160KW Cummins Diesel Generator complies with a range of international standards, συμπεριλαμβανομένου:

-

Military Standard: GJB 5785-2006

-

National Standards: GB/T2820-2002 and YD/T 502-2007

-

Industry Standard: JB/T 10303-2001

-

Environmental & Quality Certifications:

-

Noise & Vibration: Grade A

-

Exhaust Emissions: Grade A

-

Quality: Certified under YD/T502-2007

Comprehensive Support & Service Network

With a nationwide service network, our customers benefit from 24-hour technical support and prompt after-sales service. Cummins stands behind every product with robust warranty coverage and continuous technical support, ensuring your generator operates reliably when you need it most.

Εφαρμογές

The 160KW Cummins Diesel Generator is perfectly suited for:

-

Industrial Applications: Manufacturing plants, construction sites, and mining operations

-

Commercial Installations: Data centers, νοσοκομεια, and retail complexes

-

Critical Infrastructure: Emergency backup for utilities and telecommunications

-

Remote Power Supply: Off-grid power generation for remote communities and temporary installations

Optimize Your Power Supply

Choose the 160KW Cummins Diesel Generator for a combination of proven technology, robust performance, and exceptional support. Whether you need dependable standby power or a continuous power solution, this generator offers the efficiency, reliability, and advanced features to meet your energy needs.

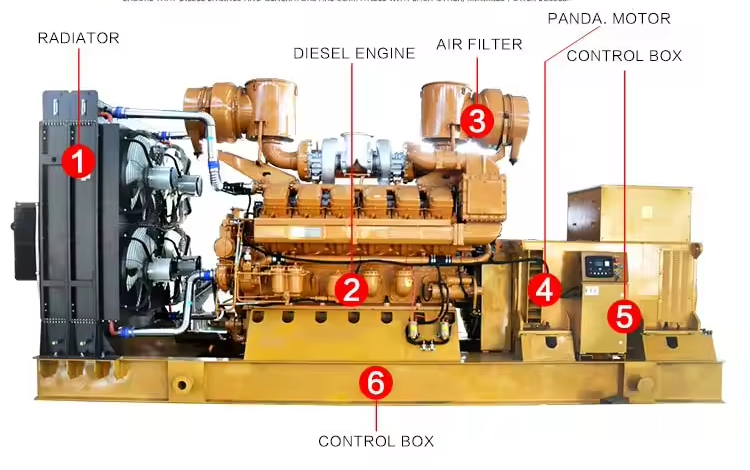

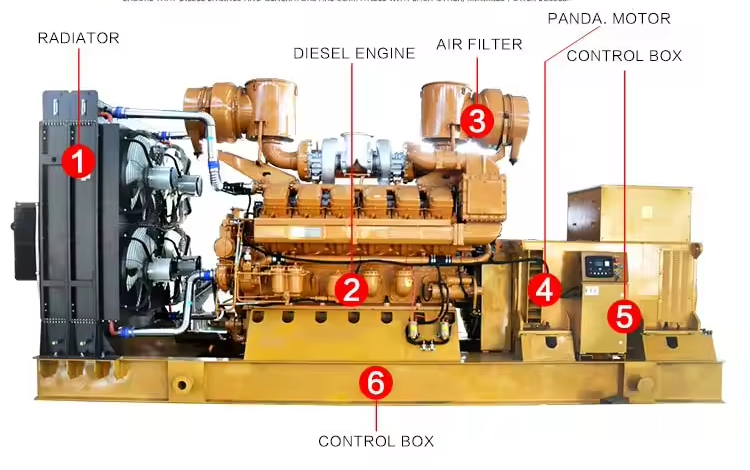

Product configuration and details

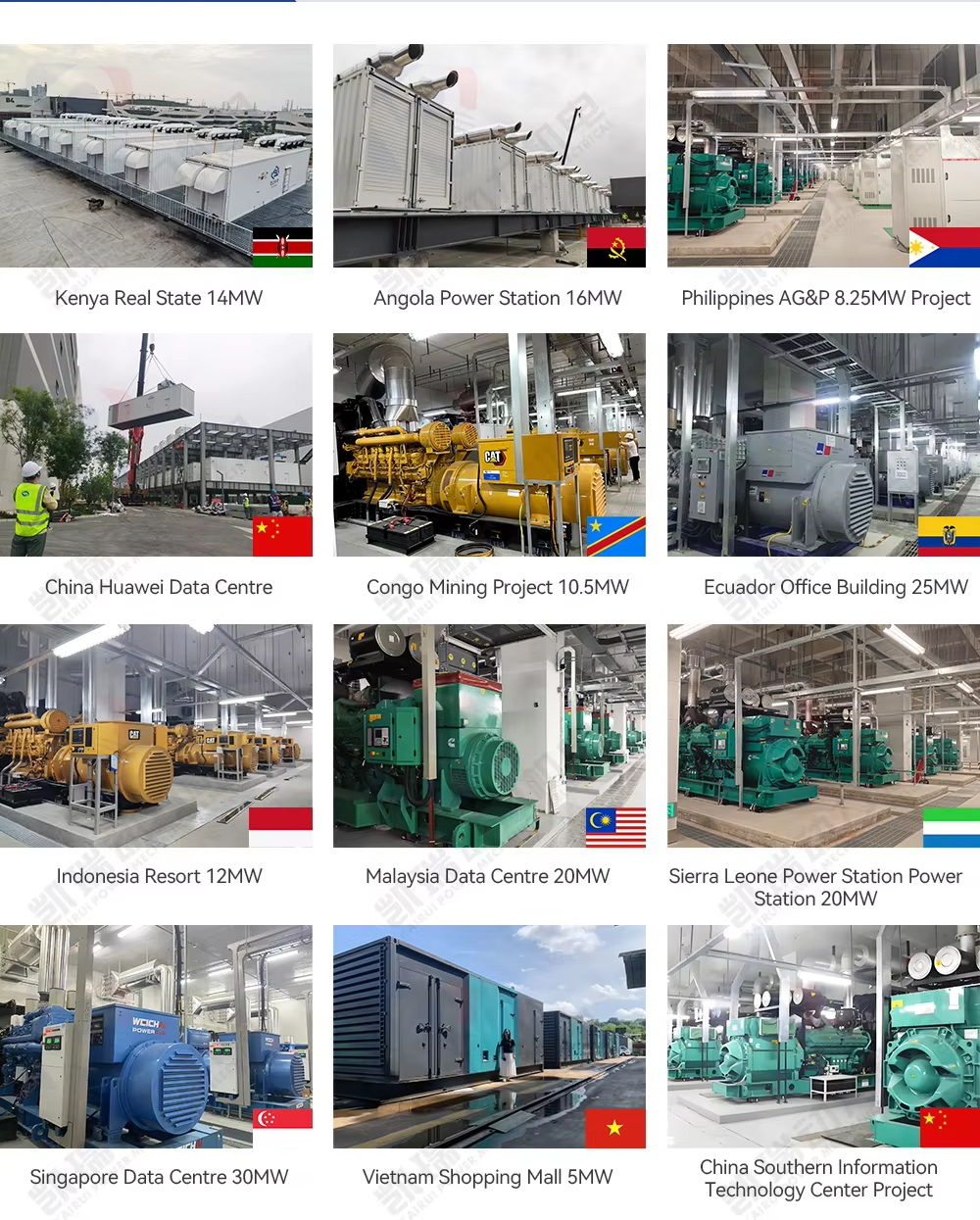

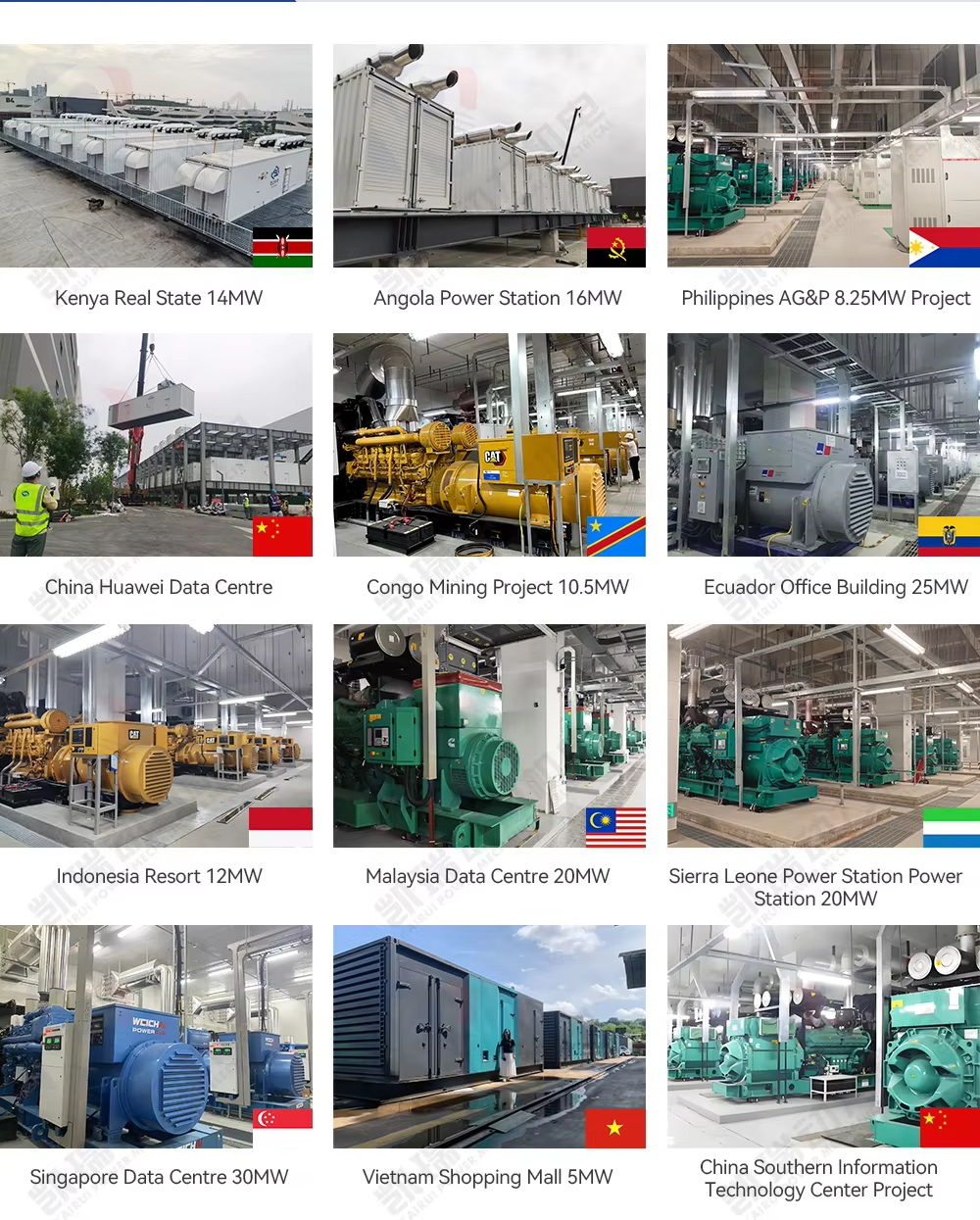

Επιτυχημένο έργο

Συσκευασία Logistics

For further information, technical support, or to request a quote, please contact our sales team today.

📧 Email: [ gmail@xn-gen.com]

📞 Τηλέφωνο: [+86 15216161715]

🌐 Ιστότοπος: [xn-gen.com]

Συντήρηση και συντήρηση γεννητριών

Στο XN-GEN, Προσφέρουμε μακροπρόθεσμα συμβόλαια συντήρησης για να παρέχουμε επαγγελματική, υψηλής ποιότητας, και χωρίς προβλήματα εξυπηρέτηση για τους πελάτες μας. Οι υπηρεσίες συντήρησής μας εξασφαλίζουν τη βέλτιστη απόδοση και μακροζωία του σετ γεννητριών σας. Ακολουθεί μια γενική κατευθυντήρια γραμμή για τις διαδικασίες συντήρησης (Λάβετε υπόψη ότι συγκεκριμένες ενέργειες ενδέχεται να διαφέρουν ανάλογα με το μοντέλο και την κατάσταση λειτουργίας κάθε γεννήτριας).

Συντήρηση ρουτίνας

Οι τακτικές επιθεωρήσεις και η συντήρηση είναι ζωτικής σημασίας για τη διασφάλιση της αξιοπιστίας της γεννήτριας σας. Οι ακόλουθοι έλεγχοι θα πρέπει να διενεργούνται τακτικά:

- Επιθεωρήστε όλα τα περιστρεφόμενα εξαρτήματα και σφίξτε τυχόν χαλαρά μπουλόνια.

- Ελέγξτε τη στάθμη λαδιού στο στροφαλοθάλαμο και προσθέστε λάδι εάν είναι απαραίτητο.

- Παρακολουθήστε τη στάθμη καυσίμου στο ρεζερβουάρ.

- Επιθεωρήστε τη στάθμη ψυκτικού στο ψυγείο.

- Εξετάστε τους αγωγούς καυσίμων και νερού για τυχόν διαρροές ή χαλαρές συνδέσεις.

- Εξασφαλίστε τα συστήματα εισαγωγής και εξάτμισης, μαζί με παρεμβύσματα κυλίνδρων, είναι σωστά σφραγισμένα.

- Καθαρίστε τυχόν λεκέδες λαδιού ή συσσώρευση σκόνης στη γεννήτρια για να διατηρήσετε ένα τακτοποιημένο μηχανοστάσιο.

Σχέδιο συντήρησης για γεννήτριες αναμονής

(Συνιστάται για εφεδρικές γεννήτριες που χρησιμοποιούνται σε κατοικημένες κοινότητες, Εμπορικά κτίρια, νοσοκομεια, Κυβερνητικές εγκαταστάσεις, Τουριστικά αξιοθέατα, Εργοστάσια, και άλλες τοποθεσίες όπου οι διακοπές ρεύματος είναι σπάνιες.)

Επαγγελματική συντήρηση (Κάθε έξι μήνες ή ετησίως)

Εκτός από τη συνήθη συντήρηση, Μια ολοκληρωμένη υπηρεσία θα πρέπει να εκτελείται κάθε έξι μήνες ή μία φορά το χρόνο:

- Διεξαγωγή διεξοδικής επιθεώρησης του καυσίμου, ηλεκτρικός, ψύξη, και συστήματα λίπανσης για τη διασφάλιση της σωστής λειτουργικότητας.

- Εκτελέστε μια δοκιμαστική λειτουργία χωρίς φορτίο για 5-10 λεπτά για τη λίπανση του συστήματος. Αξιολογήστε την απόδοση της γεννήτριας χρησιμοποιώντας ακουστική, οπτικός, και οσφρητικούς ελέγχους.

- Αντικατάσταση αναλώσιμων φίλτρων, συμπεριλαμβανομένου του αέρα, ντίζελ, λάδι, Νερό, και διαχωριστές καυσίμου-νερού.

- Στραγγίστε και αντικαταστήστε το ψυκτικό υγρό, εξασφαλίζοντας τη σωστή λειτουργία του καλοριφέρ.

- Ελέγξτε και αναπληρώστε τον ηλεκτρολύτη της μπαταρίας ή το απεσταγμένο νερό, όπως απαιτείται.

- Μετά την ολοκλήρωση της συντήρησης, Πραγματοποιήστε μια τελική επιθεώρηση και καθαρίστε το σετ γεννήτριας.

- Εκτελέστε ένα άλλο 5-10 Λεπτομερής δοκιμή χωρίς φορτίο, Καταγράψτε παραμέτρους απόδοσης, και να παρέχει προτάσεις βελτιστοποίησης πριν από την αποδοχή από τον πελάτη.

Σχέδιο συντήρησης γεννητριών συνεχούς λειτουργίας

(Συνιστάται για γεννήτριες σε εργοτάξια, συχνά εργοστάσια επιρρεπή σε διακοπές ρεύματος, περιοχές με ανεπαρκή χωρητικότητα μετασχηματιστή, Χώροι δοκιμών έργων, ή τοποθεσίες χωρίς πρόσβαση στο κύριο δίκτυο.)

Επίπεδο 1 Συντήρηση (Κάθε 50-80 Ώρες)

Αυτό περιλαμβάνει όλες τις συνήθεις εργασίες συντήρησης συν:

- Καθαρίστε το φίλτρο αέρα και αντικαταστήστε το εάν είναι απαραίτητο.

- Αντικαταστήστε το φίλτρο ντίζελ, αεροκαθαριστήρας, και φίλτρο νερού.

- Επιθεωρήστε την τάση του ιμάντα κίνησης και ρυθμίστε εάν χρειάζεται.

- Λιπάνετε όλα τα εξαρτήματα γράσου και τα κινούμενα εξαρτήματα.

- Αντικαταστήστε το ψυκτικό υγρό για να διατηρήσετε την αποτελεσματική απόδοση ψύξης.

Επίπεδο 2 Συντήρηση (Κάθε 250-300 Ώρες)

Περιλαμβάνει επίπεδο 1 Εργασίες συντήρησης, με πρόσθετους ελέγχους:

- Καθαρίστε και επιθεωρήστε τα έμβολα, καρφίτσες εμβόλου, Χιτώνια κυλίνδρων, Εμβόλου, και ρουλεμάν μπιέλας για φθορά.

- Εξετάστε το κύριο ρουλεμάν για τυχόν σημάδια χαλάρωσης ή μη φυσιολογικής φθοράς.

- Αφαιρέστε τα άλατα και τα ιζήματα από το σύστημα ψύξης για να εξασφαλίσετε τη σωστή απαγωγή θερμότητας.

- Καθαρές εναποθέσεις άνθρακα από το θάλαμο καύσης και τις διόδους εισαγωγής/εξαγωγής.

- Επιθεωρήστε και ρυθμίστε τα διάκενα των βαλβίδων, Έδρες βαλβίδων, ράβδοι ώθησης, και βραχίονες rocker.

- Καθαρίστε τους ρότορες στροβιλοσυμπιεστή και ελέγξτε τα ρουλεμάν και τις πτερωτές για φθορά, αντικατάσταση, εάν είναι απαραίτητο.

- Σφίξτε ή αντικαταστήστε τυχόν χαλαρά ή κατεστραμμένα μπουλόνια στη ζεύξη κινητήρα-κινητήρα γεννήτριας-ντίζελ.

Επίπεδο 3 Συντήρηση (Κάθε 500-1000 Ώρες)

Περιλαμβάνει επίπεδο 1 και Επίπεδο 2 Εργασίες συντήρησης, μαζί με πρόσθετες υπηρεσίες:

- Ελέγξτε και ρυθμίστε το χρονισμό ψεκασμού καυσίμου.

- Καθαρίστε το ρεζερβουάρ καυσίμου για να αφαιρέσετε τους ρύπους.

- Καθαρίστε το κάρτερ λαδιού για να αποφύγετε τη συσσώρευση λάσπης.

- Επιθεωρήστε και ελέγξτε τα μπεκ ψεκασμού καυσίμου για βέλτιστο ψεκασμό.

Ακολουθώντας αυτό το δομημένο σχέδιο συντήρησης, Οι ιδιοκτήτες γεννητριών μπορούν να εξασφαλίσουν σταθερή απόδοση, αυξημένη διάρκεια ζωής, και μειωμένος κίνδυνος απροσδόκητων αστοχιών. Η εξειδικευμένη ομάδα μας στην XN-GEN είναι αφοσιωμένη στην παροχή ανώτερων υπηρεσιών για να διατηρεί το τροφοδοτικό σας αξιόπιστο ανά πάσα στιγμή.

Για περισσότερες πληροφορίες ή για προγραμματισμό συντήρησης, Επικοινωνήστε μαζί μας σήμερα!

1. Είστε εργοστάσιο ή εμπορική εταιρεία?

Είμαστε ένα εργοστάσιο που ειδικεύεται στην παραγωγή των διαφόρων τύπων γεννητριών σύνολα. Η μονάδα παραγωγής μας εξασφαλίζει παραγωγή υψηλής ποιότητας και αυστηρό ποιοτικό έλεγχο.

2. Ποιες είναι οι κύριες αγορές σας?

Τα προϊόντα μας εξάγονται ευρέως στη Νότια Αμερική, Μέση Ανατολή, Νοτιοανατολική Ασία, και την Αφρική, κάλυψη ποικίλων αναγκών ισχύος σε διαφορετικούς κλάδους.

3. Πώς διασφαλίζετε την ποιότητα των προϊόντων?

Εφαρμόζουμε αυστηρά μέτρα ποιοτικού ελέγχου σε κάθε στάδιο της παραγωγής. Πριν την παράδοση, Όλα τα ηλεκτροπαραγωγά ζεύγη υποβάλλονται σε δοκιμές φορτίου μέσα σε ένα εμπορευματοκιβώτιο αποστολής για να διασφαλιστεί η βέλτιστη απόδοση και αξιοπιστία.

4. Ποια είναι η πολιτική εγγύησής σας?

Τα προϊόντα μας συνοδεύονται από εγγύηση ενός έτους ή 1,000 Ώρες λειτουργίας (όποιο από τα δύο συμβεί πρώτο). Παρέχουμε επίσης τεχνική υποστήριξη και υπηρεσίες ανταλλακτικών.

5. Μπορούμε να προσαρμόσουμε τη γεννήτρια με το λογότυπο ή το σχέδιό μας?

Ναι! Προσφέρουμε προσαρμοσμένη επωνυμία για εξουσιοδοτημένα λογότυπα και σχέδια, επιτρέποντάς σας να εξατομικεύσετε την εμφάνιση της γεννήτριας σύμφωνα με τις ανάγκες της επιχείρησής σας.

6. Ποιος είναι ο χρόνος παράδοσης?

Ο τυπικός χρόνος παραγωγής και παράδοσης είναι εντός 15 Εργάσιμες, ανάλογα με την ποσότητα παραγγελίας και τις απαιτήσεις προσαρμογής.

7. Πώς μπορώ να γίνω διανομέας σας?

Καλωσορίζουμε συνεργασίες με εταιρείες που διαθέτουν ισχυρούς πόρους μάρκετινγκ και δυνατότητες εξυπηρέτησης μετά την πώληση. Εάν πληροίτε αυτά τα κριτήρια και ενδιαφέρεστε να συνεργαστείτε, Μη διστάσετε να επικοινωνήσετε μαζί μας για περαιτέρω συζητήσεις.

8. Παρέχετε υποστήριξη μετά την πώληση?

Ναι! Προσφέρουμε τεχνική βοήθεια, Προμήθεια ανταλλακτικών, και απομακρυσμένη αντιμετώπιση προβλημάτων για τη διασφάλιση της απρόσκοπτης λειτουργίας των γεννητριών μας.

9: Ποιοι είναι οι όροι πληρωμής που μπορείτε να αποδεχτείτε?

- Ένας: Τ/Τ, 30% κατάθεση, 70% θα πληρωθεί πριν από την παράδοση;

- ή Τ/, 30% κατάθεση, 70% L/C με θέα;

- ή 100% L/C με θέα;

XN-GEN.COM

XN-GEN.COM