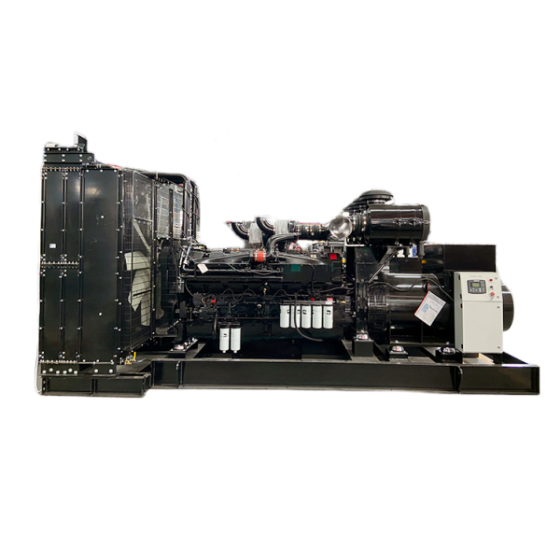

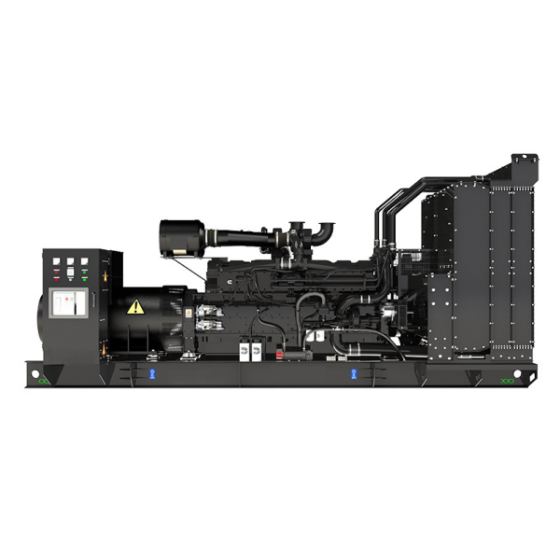

Product Overview

Our 150KW Cummins Diesel Generator integrates the advanced QSB6.7-G3 Cummins engine with the state-of-the-art UCI274F1 Stanford generator. Delivering a standby power output of 150KW and a continuous output of 135KW at a frequency of 50Hz, this system is engineered for superior fuel efficiency and outstanding operational reliability. With its high-pressure common rail and in-cylinder direct injection technology, the generator meets three-stage emission standards without the need for additional after-treatment systems.

Key Features

-

Advanced Engine Technology:

-

Extended Stroke & Four-Valve Architecture: Maximizes the expansion of combustion gases for improved power output and fuel efficiency.

-

Forced-Cooling Articulated Piston: Withstands extreme mechanical and thermal loads to ensure durability under heavy-duty operation.

-

-

Optimized Combustion & Efficiency:

-

Symmetrical Combustion Chamber & Central Injector Arrangement: Ensures a homogeneous air-fuel mixture for complete combustion, enhancing performance and reducing emissions.

-

High Power-to-Displacement Ratio: Achieves up to 30.0 kW per liter, providing robust power output while maintaining a compact engine structure.

-

-

Robust Design & Low Maintenance:

-

Enhanced Cylinder Block: Reduces noise and vibration, contributing to a smoother operation.

-

Comprehensive Control System: The advanced QS platform offers diverse control strategies that adapt to varying load conditions, ensuring optimal performance across different environments.

-

-

Global Compliance & Certification:

-

Meets international standards such as ISO 8528-2005, GB/T2820-2009, and various military, national, and industry certifications.

-

Designed and manufactured under stringent quality management systems (ISO9001/ISO9002 certified).

-

Technical Specifications

Generator Specifications

-

Model: XN-150CDG

-

Standby Power: 150KW

-

Continuous Power: 135KW

-

Frequency: 50Hz

-

Dimensions: 2500 × 1000 × 1560 mm

-

Weight: 1900 kg

-

Fuel Consumption: Approximately 207 g/kW·h

-

Voltage Regulation:

-

Steady-State: ±1%

-

Transient: -15%/+20% (voltage), -10%/+12% (frequency)

-

Engine Specifications

-

Engine Model: QSB6.7-G3 Cummins

-

Configuration: 6-cylinder inline, four-stroke

-

Compression Ratio: 17.0:1

-

Bore x Stroke: 107 × 124 mm

-

Displacement: 8.9 L

-

Rated Power: 151KW (Standby: 166KW)

-

Oil Capacity: 23.8 L

-

Coolant Capacity: 12.3 L

-

Fuel System: ECM-controlled, high-pressure common rail

-

Cooling Method: Closed-loop water cooling

-

Starting Method: DC24V electric start

-

Operating Speed: 1500 r/min

Additional Generator Details

-

Generator Model: UCI274F1 (Stanford)

-

Capacity: 175KVA

-

Voltage Options: 400V/230V

-

Design: Brushless with single bearing and rotating magnetic field

-

Excitation System: Self-excited with automatic voltage regulation

-

Insulation & Efficiency: Class H insulation, COSΦ=0.8 lagging, meeting stringent international standards (GB755, BS5000, VDE0530, etc.)

Environmental & Operational Requirements

-

Altitude: Up to 1000 m

-

Fuel Standard: 0# light diesel

-

Atmospheric Pressure: ≥89.9 kPa

-

Engine Oil Standard: CF grade/15W-40

-

Intake Temperature: ≤40°C

-

Water Quality: pH 6.5 – 8

-

Relative Humidity: ≤60%

-

Seismic Resistance: Horizontal acceleration of 0.2g; vertical acceleration of 0.1g

Standard Configuration & Accessories

Engine Components:

-

Cummins engine, diesel filter, air filter, oil filter

-

Integrated charging system and DC24V starter motor

Generator Components:

-

High-efficiency generator with integrated air switch

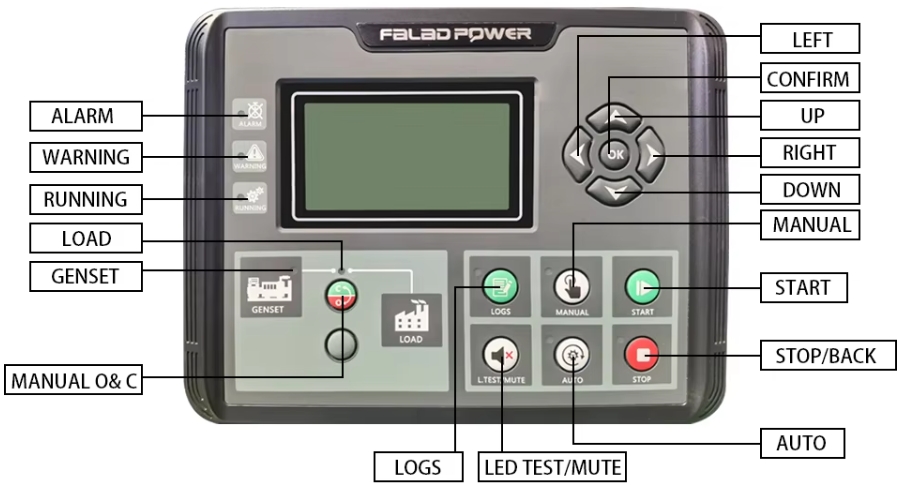

Control & Monitoring:

-

LCD digital control panel and electronic governor for precise regulation

Additional Components:

-

Radiator and steel base with vibration isolators

-

Accessories include a silencer, battery, battery cables, oil, and shock absorbers

Certifications & Warranty

-

Certifications:

-

Military Standard: GJB 5785-2006

-

National Standard: GB/T 2820-2002

-

Communication Standard: YD/T 502-2007

-

Industry Standard: JB/T 10303-2001

-

Noise & Emission Certifications: Class A for both noise and exhaust emissions

-

-

Warranty:

-

Backed by Cummins with a 1-year or 1000 operational hours full-system warranty covering the engine, generator, and control system.

-

-

After-Sales Support:

-

Enjoy round-the-clock support with our nationwide professional service network, ensuring timely maintenance and technical assistance.

-

Why Choose Our 150KW Cummins Diesel Generator?

Our generator is designed for performance and reliability in the most challenging environments. With advanced technology, rigorous quality standards, and comprehensive after-sales support, it’s the perfect solution for industrial, commercial, and mission-critical applications. Experience reduced fuel consumption, minimized maintenance downtime, and the peace of mind that comes with a trusted power solution engineered by industry leaders.

Product configuration and details

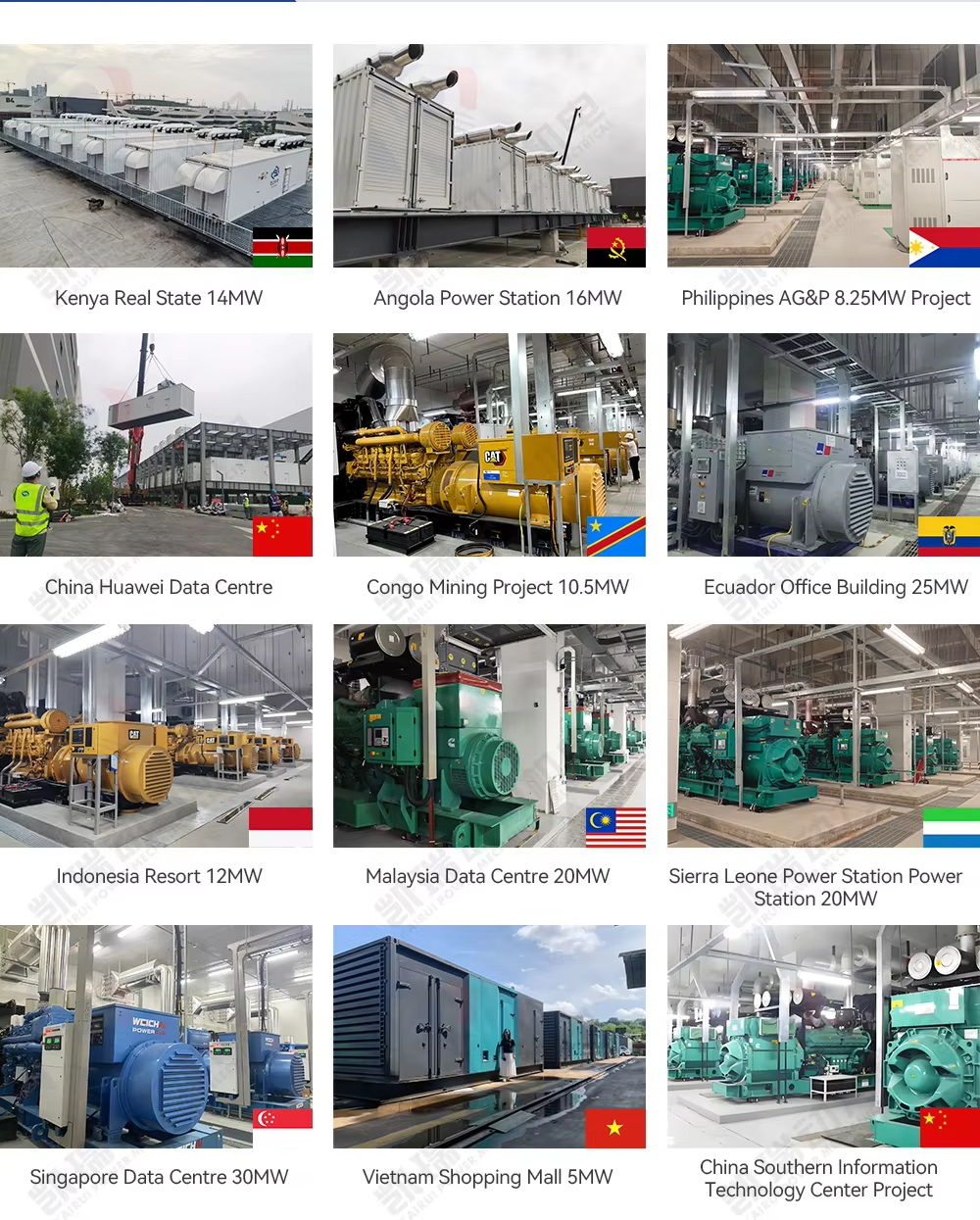

Successful Project

Logistics Packaging

Get Your 60KW Cummins Diesel Generator Today!

Whether you need a dependable backup power source for your business or a primary power solution for industrial applications, the 150KW Cummins Diesel Generator is a top-tier choice. Contact us today for pricing, availability, and customization options!

📧 Email: [ gmail@xn-gen.com]

📞 Phone: [+86 15216161715]

🌐 Website: [xn-gen.com]