Überblick

Das 320kW Diesel Generator is a high-performance, industrial-grade power solution designed for reliable and efficient operation. Built to meet GB/T2820 performance standards, this generator is ideal for both prime power und standby power applications. With a 6-cylinder, water-cooled, turbocharged diesel engine, it ensures optimal efficiency and durability in demanding environments.

Ausgangsleistung & Performance

| Speed (U/min) |

Operation Mode |

Engine Power (kW) |

Generator Power (kW) |

Apparent Power (Kva) |

| 1500 |

Prime Power |

368 |

320 |

400 |

| 1500 |

Standby-Stromversorgung |

405 |

360 |

440 |

- Prime Power: Suitable for variable load applications with no annual usage limit. When operating continuously for 24 hours, the average permissible output should not exceed 80% of the rated prime power.

- Standby-Stromversorgung: Used in emergency situations such as grid failure, with a maximum 200-hour usage per year. When running continuously for 24 hours, the average permissible output should not exceed 80% of the standby power rating.

- Overload Operation: Not permitted.

Technische Daten des Motors

| Specification |

Details |

| Motormodell |

SC13E550D2 |

| Configuration |

Inline, 4-stroke, 4-valve, water-cooled |

| Aspiration |

Mit Turbolader & intercooled |

| Combustion Type |

Direct injection |

| Cylinder Liner |

Wet cylinder liner |

| Number of Cylinders |

6 |

| Bore × Stroke |

130mm × 161mm |

| Verschiebung |

12.8L |

| Verdichtungsverhältnis |

17:1 |

| Firing Order |

1-5-3-6-2-4 |

| Injection Timing |

14° BTDC |

| Dry Weight |

1164 Kg |

| Overall Dimensions |

1856 × 1000 × 1354 Mm |

| Crankshaft Rotation |

Counterclockwise (viewed from flywheel) |

| Flywheel Housing |

SAE 1# |

| Flywheel |

SAE 14# (133 teeth) |

Benzinverbrauch (at 1500r/min)

| Load (%) |

Benzinverbrauch (L/h) |

| 25% |

25.1 |

| 50% |

44.4 |

| 75% |

64.3 |

| 100% |

87.9 |

| 110% |

97.7 |

Kraftstoffsystem

- Fuel Injection Pump: Longkou PZ inline pump

- Governor: Electronic control

- Fuel Transfer Pump: Mechanical type

- Injector Type: Multi-hole type

- Injection Pressure: 250 kg/cm²

- Fuel Filter: Spin-on, full-flow

- Kraftstoffart: Light diesel

Schmiersystem

- Lubrication Type: Pressure & splash system

- Oil Pump: Gear-driven, crankshaft-driven

- Oil Filter: Spin-on, full-flow

- Ölkapazität: Maximum 36L, Minimum 33L

- Oil Pan Tilt Limits:

- Front tilt: 25°

- Rear tilt: 35°

- Left/Right tilt: 35°

Kühlsystem

- Cooling Type: Freshwater circulation cooling

- Kühlmittelkapazität (Engine Only): 23.2L

- Minimum Pressure Cap Rating: 70 kPa

- Water Pump: Centrifugal, belt-driven

- Water Pump Flow Rate: 600L/min at 1500r/min

- Thermostat:

- Opening Temperature: 85°C

- Fully Open Temperature: 95°C

- Radiator Fan: Plastic, blow-through type

- Diameter: 1000Mm

- Number of Blades: 8

- Power Consumption: 15 kW

- Maximum Coolant Temperature (Standby/Prime Power): 104°C / 100°C

Valve Train & Timing

- Valve Configuration: Overhead valves (OHV)

- Number of Valves per Cylinder: 2 intake, 2 exhaust

- Cold Valve Clearance:

- Intake: 0.40Mm

- Exhaust: 0.65Mm

Valve Timing

| Valve |

Opening Timing |

Closing Timing |

| Intake |

15° BTDC |

30° ABDC |

| Exhaust |

45° BBDC |

13° ATDC |

Air Intake & Exhaust System

| Parameter |

Value |

| Air Intake Volume |

35.3 m³/min (1500U/min) |

| Exhaust Gas Volume |

79.7 m³/min (1500U/min) |

| Exhaust Temperature |

600°C |

| Max Intake Resistance |

New Filter: 3 kPa Dirty Filter: 6 kPa |

| Max Exhaust Backpressure |

10 kPa |

| Intercooler Resistance Limit |

10 kPa |

Electrical System

- Alternator Output: 28V × 55A

- Voltage Regulator: Integrated circuit-type regulator

- Starter Motor: 24V × 7.5kW

- Battery Voltage: 24V

- Battery Capacity: 180AH

Anträge

Das 320kW Diesel Generator is suitable for:

- Industrial power backup

- Construction sites

- Commercial facilities

- Emergency standby applications

- Continuous power supply for remote areas

Technische Zeichnungen:

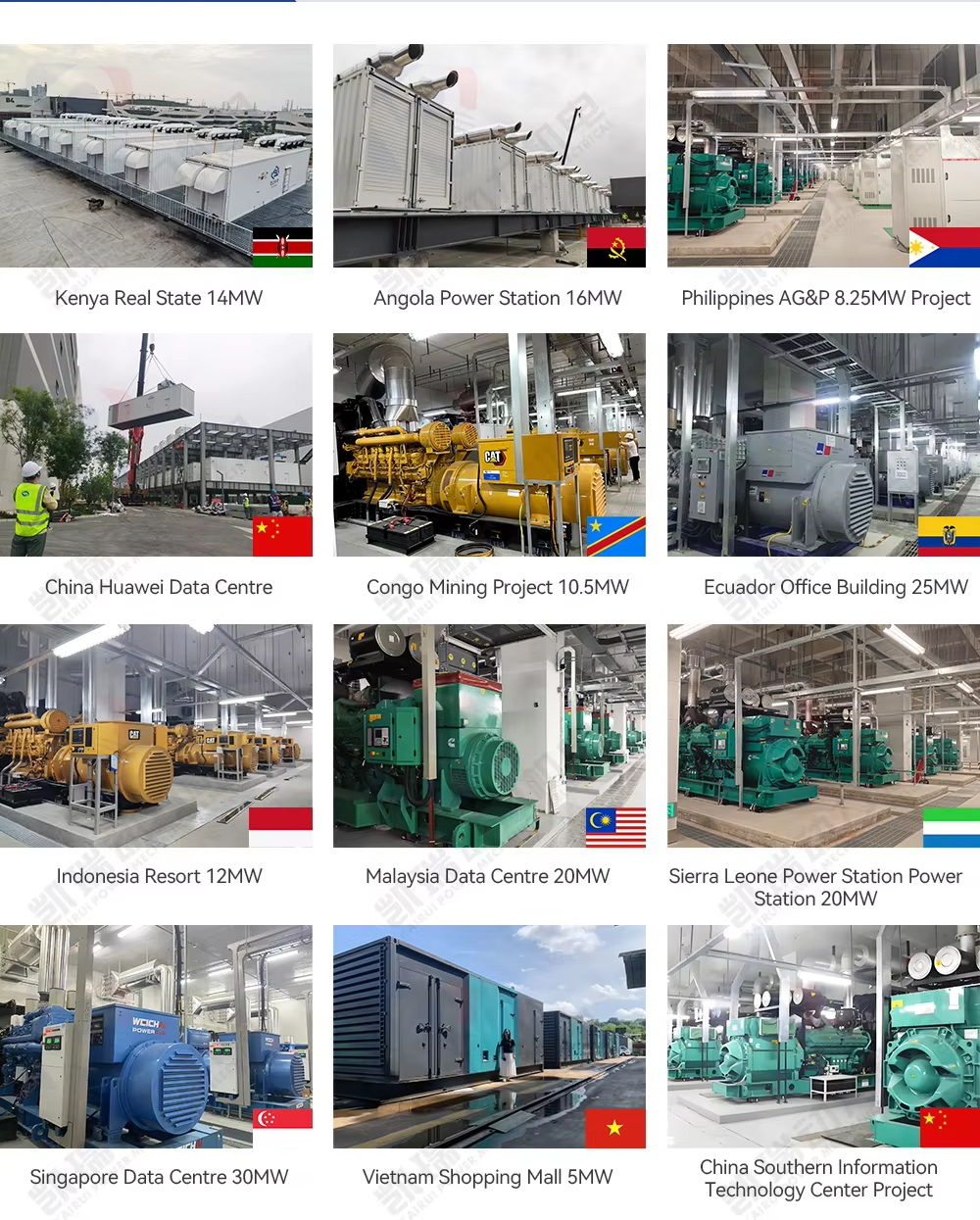

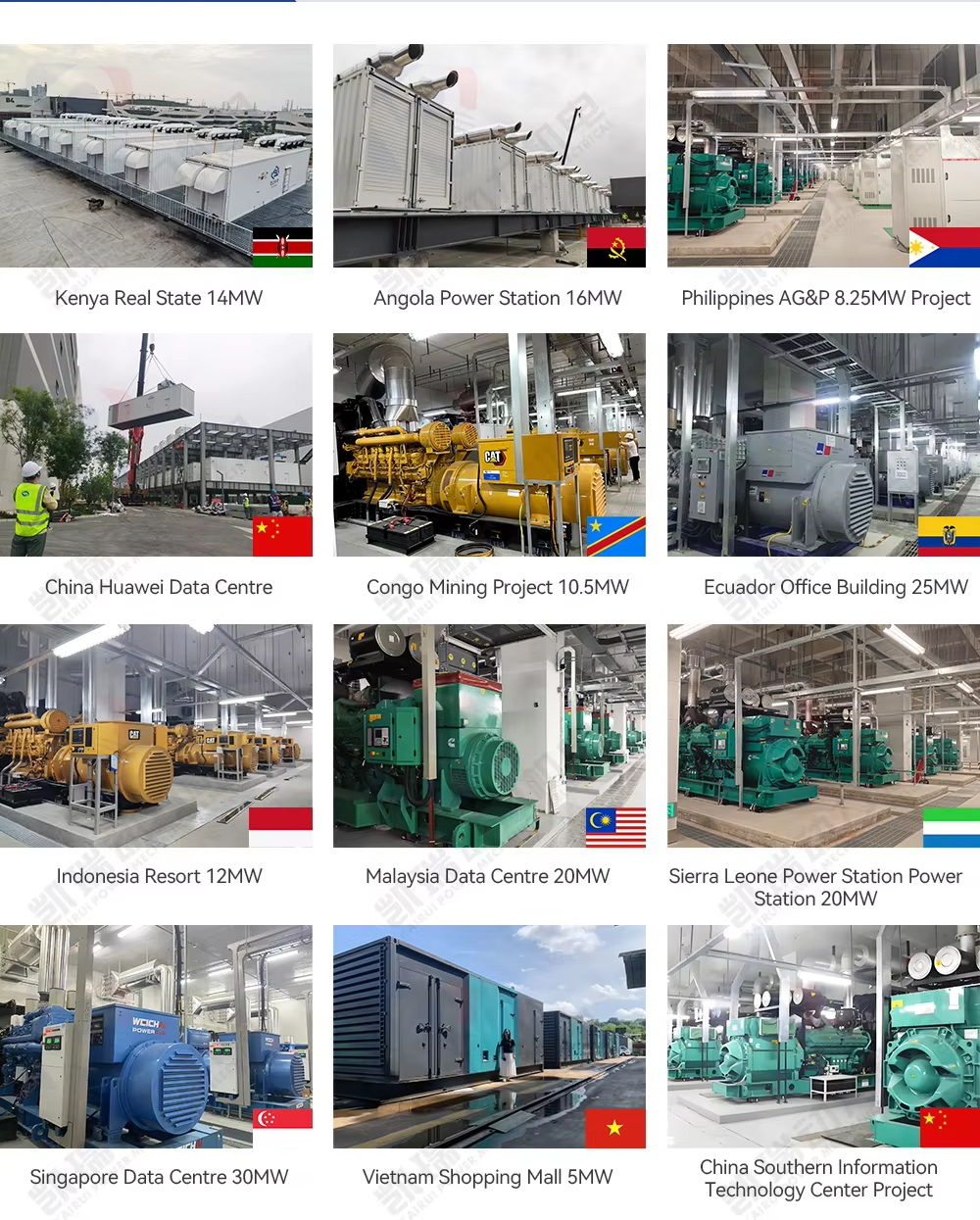

Erfolgreiches Projekt

Logistik Verpackung

Conclusion

With a powerful, fuel-efficient engine, robust cooling system, und high-performance alternator, the 320kW Diesel Generator delivers reliable and durable performance for critical power needs. Built to meet international standards, this generator is an ideal choice for industrial, Kommerziell, and emergency applications.

📧 E-Mail: [ gmail@xn-gen.com]

📞 Telefon: [+86 15216161715]

🌐 Website: [xn-gen.com]

Wartung und Instandhaltung von Generatoren

Bei XN-GEN, Wir bieten langfristige Wartungsverträge an, um Ihnen eine professionelle, hochwertig, und problemloser Service für unsere Kunden. Unsere Wartungsdienstleistungen gewährleisten die optimale Leistung und Langlebigkeit Ihres Stromaggregats. Im Folgenden finden Sie eine allgemeine Richtlinie für Wartungsverfahren (Bitte beachten Sie, dass bestimmte Maßnahmen je nach Modell und Betriebsstatus des jeweiligen Stromaggregats variieren können).

Routinemäßige Wartung

Regelmäßige Inspektionen und Wartungen sind entscheidend, um die Zuverlässigkeit Ihres Generators zu gewährleisten. Die folgenden Überprüfungen sollten regelmäßig durchgeführt werden:

- Überprüfen Sie alle rotierenden Komponenten und ziehen Sie alle losen Schrauben fest.

- Ölstand im Kurbelgehäuse prüfen und ggf. Öl nachfüllen.

- Überwachen Sie den Kraftstoffstand im Tank.

- Prüfen Sie den Kühlmittelstand im Kühler.

- Untersuchen Sie Kraftstoff- und Wasserleitungen auf Lecks oder lose Verbindungen..

- Stellen Sie die Ansaug- und Abgassysteme sicher, zusammen mit Zylinderdichtungen, ordnungsgemäß abgedichtet sind.

- Reinigen Sie Ölflecken oder Staubansammlungen auf dem Generator, um einen aufgeräumten Maschinenraum zu gewährleisten.

Wartungsplan für Standby-Generatoren

(Empfohlen für Notstromaggregate, die in Wohngemeinschaften eingesetzt werden, Gewerbegebäude, Krankenhäuser, Staatliche Einrichtungen, Sehenswürdigkeiten, Fabriken, und andere Orte, an denen Stromausfälle selten sind.)

Professionelle Wartung (Alle sechs Monate oder jährlich)

Neben der routinemäßigen Wartung, Ein umfassender Service sollte alle sechs Monate oder einmal im Jahr durchgeführt werden:

- Führen Sie eine gründliche Inspektion des Kraftstoffs durch, elektrisch, Kühlung, und Schmiersysteme, um eine einwandfreie Funktion zu gewährleisten.

- Führen Sie einen Testlauf ohne Auslastung durch für 5-10 Minuten, um das System zu schmieren. Beurteilen Sie die Leistung des Generators mit Hilfe von auditiver, visuell, und Geruchskontrollen.

- Verbrauchsfilter austauschen, inklusive Luft, Diesel, Öl, Wasser, und Kraftstoff-Wasser-Abscheider.

- Kühlmittel ablassen und austauschen, Sicherstellung der ordnungsgemäßen Funktion des Heizkörpers.

- Überprüfen Sie den Batterieelektrolyten oder destilliertes Wasser und füllen Sie ihn bei Bedarf auf.

- Nach Abschluss der Wartung, Führen Sie eine Endkontrolle durch und reinigen Sie das Stromaggregat.

- Führen Sie eine weitere 5-10 Minutenlanger Leerlauftest, Leistungsparameter aufzeichnen, und geben Optimierungsempfehlungen vor der Kundenakzeptanz.

Wartungsplan für Generatoren im Dauerbetrieb

(Empfohlen für Generatoren auf Baustellen, Fabriken, die häufig von Stromausfällen betroffen sind, Bereiche mit unzureichender Transformatorkapazität, Projekt-Teststandorte, oder Orte ohne Zugang zum Hauptnetz.)

Niveau 1 Instandhaltung (Jeder 50-80 Stunden)

Dazu gehören alle routinemäßigen Wartungsaufgaben sowie:

- Reinigen Sie den Luftfilter und tauschen Sie ihn bei Bedarf aus.

- Ersetzen Sie den Dieselfilter, Luftfilter, und Wasserfilter.

- Überprüfen Sie die Spannung des Antriebsriemens und passen Sie ihn bei Bedarf an.

- Schmieren Sie alle Schmiernippel und beweglichen Komponenten.

- Ersetzen Sie das Kühlmittel, um eine effektive Kühlleistung zu erhalten.

Niveau 2 Instandhaltung (Jeder 250-300 Stunden)

Beinhaltet Level 1 Wartungsaufgaben, mit zusätzlichen Prüfungen:

- Kolben reinigen und inspizieren, Kolbenbolzen, Zylinderlaufbuchsen, Kolbenringe, und Pleuellager für Verschleiß.

- Untersuchen Sie das Hauptlager auf Anzeichen von Lockerheit oder abnormalem Verschleiß..

- Entfernen Sie Zunder und Ablagerungen aus dem Kühlsystem, um eine ordnungsgemäße Wärmeableitung zu gewährleisten.

- Klare Kohlenstoffablagerungen aus der Brennkammer und den Einlass-/Auslasskanälen.

- Prüfen und Einstellen von Ventilspielen, Ventilsitze, Schubstangen, und Kipphebel.

- Reinigen Sie die Rotoren der Turbolader und prüfen Sie Lager und Laufräder auf Verschleiß, ggf. austauschen.

- Lösen oder ersetzen Sie alle gelösten oder beschädigten Schrauben in der Kupplung zwischen Generator und Dieselmotor.

Niveau 3 Instandhaltung (Jeder 500-1000 Stunden)

Beinhaltet Level 1 und Ebene 2 Wartungsaufgaben, zusammen mit zusätzlichen Dienstleistungen:

- Kraftstoffeinspritzzeitpunkt prüfen und anpassen.

- Reinigen Sie den Kraftstofftank, um Verunreinigungen zu entfernen.

- Reinigen Sie die Ölwanne, um Schlammbildung zu vermeiden.

- Inspizieren und testen Sie die Einspritzdüsen auf optimale Zerstäubung.

Indem Sie diesen strukturierten Wartungsplan befolgen, Generatorbesitzer können eine gleichbleibende Leistung sicherstellen, Erhöhte Lebensdauer, und reduziertes Risiko unerwarteter Ausfälle. Unser Expertenteam bei XN-GEN ist bestrebt, einen erstklassigen Service zu bieten, damit Ihre Stromversorgung jederzeit zuverlässig ist.

Für weitere Informationen oder um Wartungsarbeiten zu planen, Kontaktieren Sie uns noch heute!

1. Sind Sie eine Fabrik oder ein Handelsunternehmen??

Wir sind eine Fabrik, die sich auf die Herstellung verschiedener Arten von Stromaggregaten spezialisiert hat. Unsere Produktionsstätte gewährleistet eine qualitativ hochwertige Produktion und eine strenge Qualitätskontrolle.

2. Was sind Ihre Hauptmärkte??

Unsere Produkte werden in großem Umfang nach Südamerika exportiert, Naher Osten, Südostasien, und Afrika, Deckung des unterschiedlichen Energiebedarfs in verschiedenen Branchen.

3. Wie stellen Sie die Produktqualität sicher??

Wir führen in jeder Phase der Produktion strenge Qualitätskontrollmaßnahmen durch. Vor der Auslieferung, Alle Stromaggregate werden in einem Schiffscontainer einem Lasttest unterzogen, um eine optimale Leistung und Zuverlässigkeit zu gewährleisten.

4. Was ist Ihre Garantierichtlinie??

Unsere Produkte werden mit einer branchenüblichen Garantie von einem Jahr oder 1,000 Betriebszeiten (je nachdem, was zuerst eintritt). Wir bieten auch technischen Support und Ersatzteilservice an.

5. Können wir den Generator mit unserem Logo oder Design anpassen??

Ja! Wir bieten kundenspezifisches Branding für autorisierte Logos und Designs, So können Sie das Erscheinungsbild des Generators an Ihre Geschäftsanforderungen anpassen.

6. Was ist Ihre Lieferzeit??

Unsere Standard-Produktions- und Lieferzeit liegt innerhalb 15 Arbeitstage, abhängig von der Bestellmenge und den Anforderungen an die Anpassung.

7. Wie kann ich Ihr Vertriebspartner werden??

Wir begrüßen Partnerschaften mit Unternehmen, die über starke Marketingressourcen und After-Sales-Service-Fähigkeiten verfügen. Wenn Sie diese Kriterien erfüllen und an einer Zusammenarbeit interessiert sind, Kontaktieren Sie uns gerne für weitere Gespräche.

8. Bieten Sie After-Sales-Support an??

Ja! Wir bieten technische Unterstützung, Ersatzteilversorgung, und Fehlerbehebung aus der Ferne, um einen reibungslosen Betrieb unserer Stromaggregate zu gewährleisten.

9: Welche Zahlungsbedingungen können Sie akzeptieren??

- Ein: T/T, 30% deponieren, 70% werden vor der Lieferung bezahlt;

- oder T/, 30% deponieren, 70% L/C auf Sicht;

- oder 100% L/C auf Sicht;

XN-GEN.COM

XN-GEN.COM