Table of Contents

- Introduction

- Effects of Air in the Fuel System

- Identifying and Fixing Fuel Line Leaks

- 3.1 Low-Pressure vs. High-Pressure Fuel Lines

- 3.2 Common Causes of Fuel Leaks

- 3.3 Methods for Detecting Fuel Leaks

- Removing Air from the Fuel System

- 4.1 Standard Air Removal Method

- 4.2 Alternative Air Removal Methods in Emergency Situations

- Common Diesel Generator Faults and Inspection Methods

- 5.1 Diesel Generator Fails to Start

- 5.2 Power Output Insufficiency

- 5.3 Automatic Shutdown Causes and Solutions

- Выснова

1. Introduction

Diesel generators rely on a well-functioning fuel system to operate smoothly. If air enters the fuel system, it can cause difficulties in starting or lead to unstable operation. In severe cases, the generator may completely fail to function, causing downtime and inconvenience. This document provides a detailed analysis of common fuel system issues, their causes, and effective troubleshooting methods.

2. Effects of Air in the Fuel System

If air enters the fuel system, the generator may experience:

- Difficulty starting

- Frequent stalling after ignition

- Reduced power output due to fuel supply disruption

- Complete failure to start due to fuel starvation

Air is highly compressible, unlike liquid fuel, which affects fuel delivery pressure. If air infiltrates the fuel line, the suction force from the fuel tank weakens, possibly leading to a complete fuel flow interruption.

3. Identifying and Fixing Fuel Line Leaks

3.1 Low-Pressure vs. High-Pressure Fuel Lines

The fuel system consists of:

- Low-Pressure Fuel Line: From the fuel tank to the fuel injection pump (pre-fuel delivery phase).

- High-Pressure Fuel Line: From the high-pressure fuel pump to the fuel injectors.

Air leaks typically occur in the low-pressure fuel line, while high-pressure lines primarily experience fuel leaks without air ingress.

3.2 Common Causes of Fuel Leaks

- Damaged or worn-out rubber fuel hoses

- Loose or faulty pipe fittings

- Degraded gaskets and seals due to wear or improper installation

3.3 Methods for Detecting Fuel Leaks

Method 1: Bleed the fuel system and observe where air re-enters—this indicates the leak location.

Method 2: Loosen the bleed screw on the injection pump and manually operate the fuel pump. If continuous air bubbles appear, the leak is between the fuel tank and the fuel pump. To locate the exact leak, remove the section of the pipe, pressurize it with air, and submerge it in water to observe bubble formation.

4. Removing Air from the Fuel System

4.1 Standard Air Removal Method

- Loosen the bleed screw on the fuel injection pump.

- Manually operate the priming pump until a steady, bubble-free fuel stream emerges.

- Tighten the bleed screw and restore the pump to its original position.

4.2 Alternative Air Removal Methods in Emergency Situations

If no tools are available:

- Loosen a fuel line connection between the fuel filter and injection pump.

- Manually operate the priming pump until bubble-free fuel appears.

- Tighten the connection while continuing to pump fuel.

- If unable to loosen connections, repeatedly pump the primer to increase line pressure until excess air escapes via the overflow valve.

5. Common Diesel Generator Faults and Inspection Methods

5.1 Diesel Generator Fails to Start

A successful startup requires:

- Sufficient cranking speed

- Good cylinder compression

- Properly atomized fuel injection

- Adequate fuel temperature for ignition

Troubleshooting Steps:

- Electrical System Check: If pressing the start button does not engage the motor, check for disconnected or faulty wiring.

- Fuel System Check: If the starter runs but no ignition occurs, check for air or water in the fuel.

- Compression Test: If the engine turns but does not start, check for low cylinder compression using a flywheel resistance test.

- Cold Weather Solutions: Preheat the engine using warm water or steam if thickened fuel causes resistance.

5.2 Power Output Insufficiency

Symptoms:

- Rough idling at low speeds

- Black smoke from the exhaust at high speeds

Inspection Steps:

- If full throttle is achievable with no load, the issue lies in the connected equipment.

- If the engine fails to reach top speed, inspect the fuel system or compression levels.

- Check exhaust manifold temperatures—if one cylinder is cooler, it may not be firing properly.

- Feel the high-pressure fuel lines:

- Weak pulse and normal temperature: Injector may be stuck open.

- Strong pulse and higher temperature: Injector may be stuck closed.

- No pulse at high speeds: Fuel pump failure.

5.3 Automatic Shutdown Causes and Solutions

Primary Causes:

- Fuel Supply Interruption:

- Gradual decrease in engine speed and power loss

- Verify fuel lines for blockages or leaks

- Mechanical Failure:

- High oil temperature and increasing resistance suggest a seized piston.

- Increased mechanical noise and sudden power loss could indicate a damaged crankshaft.

Troubleshooting Steps:

- If the engine stops gradually and the flywheel turns normally after stopping, fuel supply is the likely cause.

- If the flywheel resists movement post-shutdown and metal debris is found in the oil, internal damage is suspected.

6. Выснова

A properly functioning fuel system is essential for diesel generator reliability. Regular inspections, prompt air removal, and leak detection can prevent startup issues, power losses, and unexpected shutdowns. By following systematic troubleshooting methods, operators can minimize downtime and ensure efficient generator performance.

7.Diesel Fuel System FAQ

7.1. What are the five main components of a diesel fuel system?

A diesel vehicle’s fuel system consists of five key components:

- Fuel Tank – Stores the diesel fuel.

- Fuel Lines – Transport fuel from the tank to the engine.

- Fuel Filter – Removes impurities and contaminants.

- Fuel Pump – Delivers fuel at the required pressure.

- Fuel Injectors – Atomize and inject fuel into the combustion chamber.

Understanding these components helps ensure proper maintenance and optimal performance.

7.2. What is the fuel supply system in a diesel generator?

A diesel generator’s fuel supply and regulation system includes:

- Fuel Transfer Pump – Draws fuel from the tank.

- Fuel Filters – Remove debris and impurities.

- Injection Pump – Pressurizes fuel for injection.

- Governor – Controls engine speed.

- Injectors – Deliver fuel to the cylinders.

- Fuel Lines – Connect all fuel system components.

When the generator is running, the transfer pump pulls fuel from the tank, passing it through filters before reaching the injection pump and injectors.

7.3. How does a diesel fuel system work?

The diesel fuel system precisely measures, pressurizes, and atomizes fuel before injecting it into the engine’s cylinders at the right moment. When mixed with compressed hot air, the fuel ignites, powering the engine.

7.4. What type of fuel does a diesel generator use?

Diesel generators typically use one of three fuel types:

- D1 Diesel – Suitable for cold temperatures due to better flow characteristics.

- D2 Diesel – Standard diesel fuel, commonly used in warm conditions.

- D1/D2 Blend – A mix used to optimize performance based on climate and engine requirements.

Choosing the right fuel ensures efficiency and longevity of the generator.

7.5. What are the two types of diesel fuel injection systems?

There are two primary types of diesel fuel injection systems:

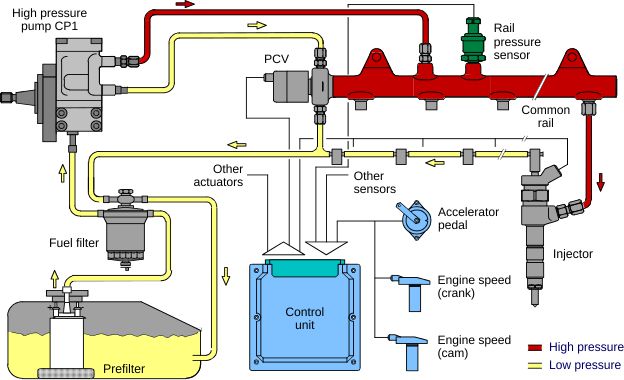

- Common Rail Injection – Uses a high-pressure fuel rail to supply fuel to all injectors simultaneously, offering better efficiency and lower emissions.

- Mechanical Injection – Uses individual pumps for each injector, often found in older diesel engines.

Understanding these systems can help in choosing the right diesel vehicle.

7.6. What is the difference between gasoline and diesel fuel systems?

- In diesel engines, air is compressed first, and then fuel is injected, where it ignites due to high temperature and pressure.

- In gasoline engines, fuel and air are mixed before compression and ignited by a spark plug.

- Diesel fuel is denser, evaporates more slowly, and provides better fuel economy than gasoline.

Each system has its own advantages, making them suitable for different applications.

Xn-gen.com

Xn-gen.com