نظرة عامة على المنتج

The XN-600KW Diesel Generator delivers robust, uninterrupted power for demanding industrial, commercial, and emergency backup applications. Engineered with precision and built to ISO 3046 المعايير, this generator combines cutting-edge technology with exceptional durability, ensuring peak performance even in extreme conditions.

Key Benefits

✅ Unmatched Reliability: Designed for 24/7 operation in harsh environments.

✅ Fuel Efficiency: Optimized consumption (120 لتر / ساعة عند التحميل الكامل) reduces operational costs.

✅ Low Maintenance: Brushless design + corrosion-resistant components.

✅ Global Compliance: يفي ب ISO, BS, IEC, CSA, and AS standards.

المواصفات الفنية

مقاييس الأداء

- نموذج: XN-600GFS

- الطاقة المقدرة: 600ك و / 750كيه فا

- Standby Power: 660ك و / 825كيه فا

- ضغط: 400/230V, 3-طور

- تردد: 50هرتز

- عامل القدرة: 0.8 (متخلفه)

- كفاءة: 93.7%

محرك ديزل متقدم

- نموذج: 6KTAA25-G32 Turbocharged Engine

- انتاج الطاقة: 685ك و / 754HP

- اسطوانات: 6 | التشريد: 25.2L

- نظام التبريد: Closed-loop water cooling (55L capacity)

- استهلاك الوقود: 120 لتر / ساعة عند التحميل الكامل

- درجة حرارة العادم: ≤600 درجة مئوية

Generator Unit

- نموذج: XN-600 Synchronous Generator

- تنظيم الجهد: ±1٪ (Brushless self-excited)

- حماية: IP23-rated enclosure

- فئة العزل: F (High thermal resistance)

التحكم الذكي & Safety

HGM6110 Automated Control System:

- Real-time LED monitoring of RPM, voltage, درجة حرارة سائل التبريد, ضغط الزيت, and fuel levels.

- Multi-Layer Protection: Auto-shutdown for faults (overheating, low oil, overspeed).

- Battery Backup: Dual 12V 120AH lead-acid batteries for fail-safe startups.

Design & المتانه

- ابعاد: 4300 x 1750 x 2180 mm (Compact footprint for easy installation).

- ثقل: 4600 ك جم (Reinforced steel frame for vibration resistance).

- نظام التبريد: High-capacity radiator maintains optimal temps (82–93°C operating range).

Ideal Applications

- Industrial: Factories, mining operations, construction sites.

- Commercial: Data centers, المستشفيات, shopping malls.

- Emergency Backup: Telecom towers, utilities, disaster recovery.

Why Choose the XN-600KW?

- Proven Longevity: Precision-engineered components for a 20,000+ hour service life.

- Emission Compliance: Meets global ISO 3046 emission standards.

- Global Support: 24/7 technical assistance and spare parts availability.

الشهادات & Standards

- Engine Performance: أيزو 3046, جيجابايت 755, BS5000.

- Safety: IEC34-1, وكالة الفضاء الكندية 22.2, أ 2359, VDE0530.

600 kW Diesel Generator FAQ

How much electricity can a 600 kW Diesel generator produce?

A 600 kW diesel generator can supply power for heavy machinery, HVAC systems, مراكز البيانات, and large-scale operations. It is typically used in applications that require a high power output.

How much diesel does a 600 kW Diesel generator consume?

Below is an approximate fuel consumption table for different generator capacities:

| Generator Capacity (kW) |

1/4 Load (Gallons/Hour) |

Full Load (Gallons/Hour) |

| 500 kW |

11.0 |

35.7 |

| 600 kW |

13.2 |

42.8 |

| 750 kW |

16.3 |

53.4 |

| 1000 kW |

21.6 |

71.1 |

What is the rated current of a 600 kW Diesel generator?

The Ashok Leyland 600 kVA diesel generator has a rated current of 834 amps.

What is the fuel consumption of a 600 kW Diesel generator?

At 75% load, the fuel consumption of a 600 kVA generator is approximately 90 liters per hour (l/h).

الرسومات الفنية:

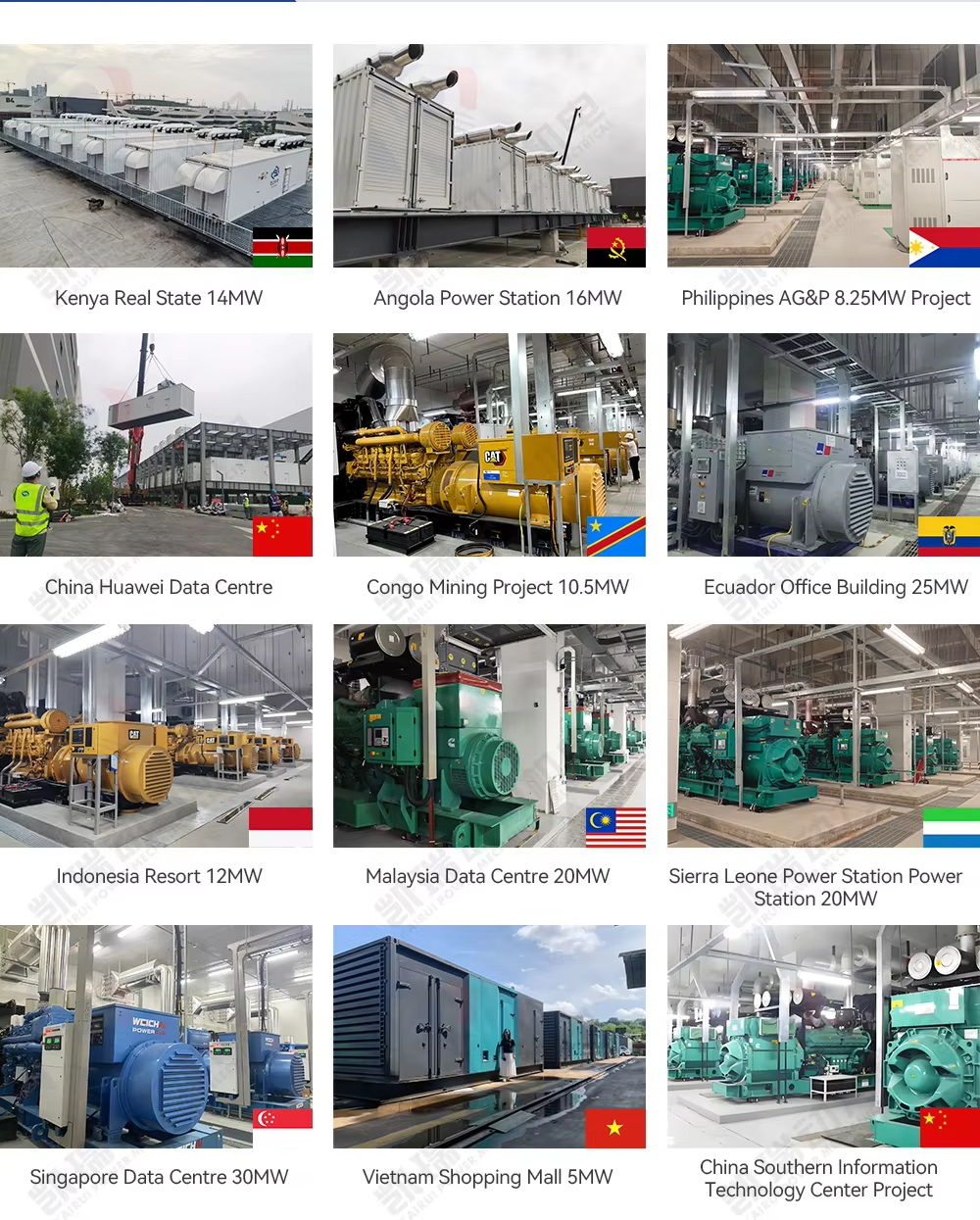

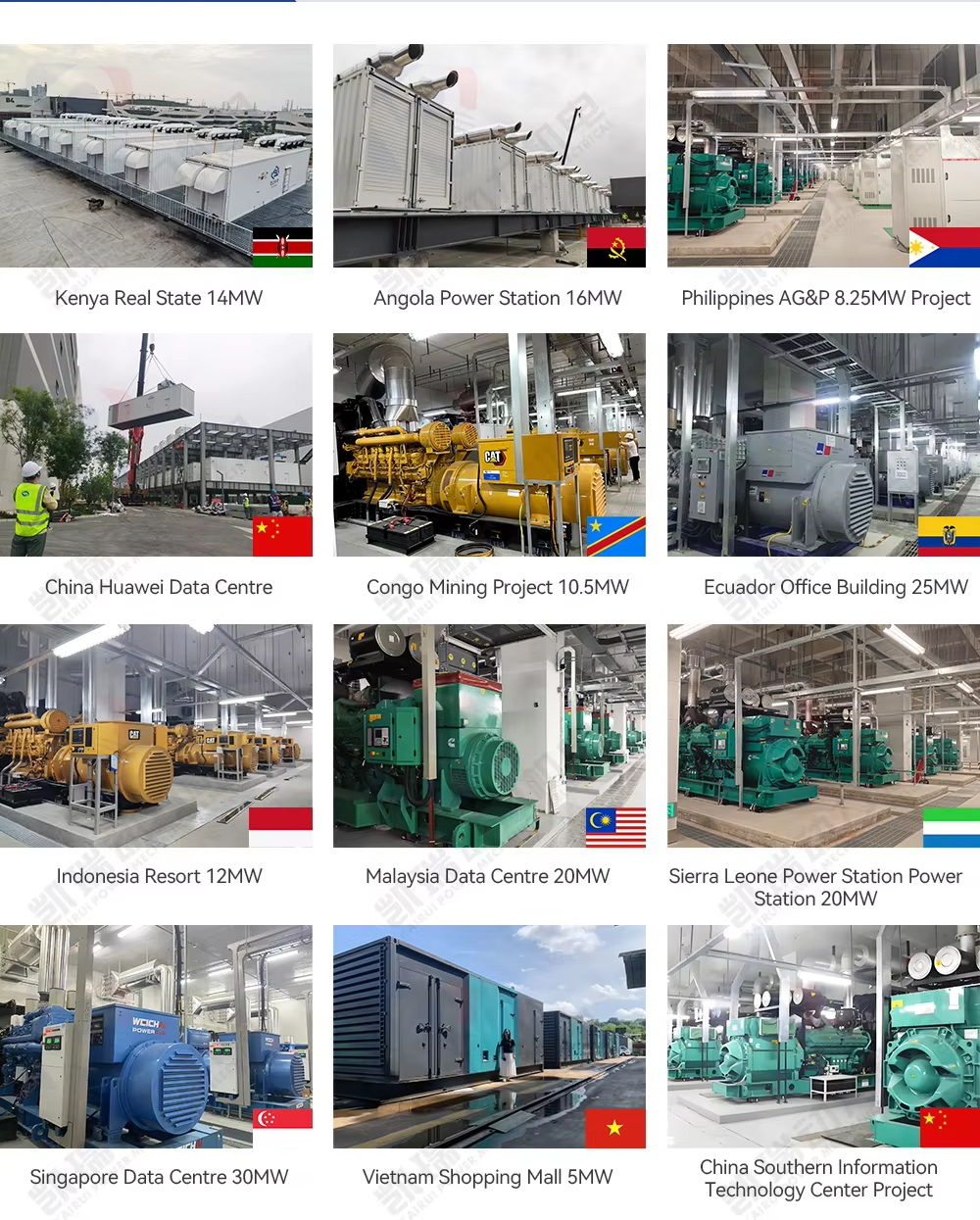

مشروع ناجح

التعبئة والتغليف اللوجستية

🚀 Get in Touch Today! Contact us for pricing, customization options, and availability.

📧 البريد الإلكتروني: [ gmail@xn-gen.com]

📞 الهاتف: [+86 15216161715]

🌐 الموقع الإلكتروني: [xn-gen.com]

صيانة وصيانة المولدات

في XN-GEN, نحن نقدم اتفاقيات صيانة طويلة الأجل لتوفير المهنية, جودة عالية, وخدمة خالية من المتاعب لعملائنا. تضمن خدمات الصيانة لدينا الأداء الأمثل وطول العمر لمجموعة المولدات الخاصة بك. فيما يلي إرشادات عامة لإجراءات الصيانة (يرجى ملاحظة أن إجراءات محددة قد تختلف بناء على الطراز والحالة التشغيلية لكل مجموعة مولدات).

الصيانة الروتينية

تعد عمليات الفحص والصيانة المنتظمة أمرا بالغ الأهمية لضمان موثوقية المولد الخاص بك. يجب إجراء الفحوصات التالية بانتظام:

- افحص جميع المكونات الدوارة وشد أي مسامير مفكوكة.

- تحقق من مستوى الزيت في علبة المرافق وأضف الزيت إذا لزم الأمر.

- مراقبة مستويات الوقود في الخزان.

- افحص مستوى سائل التبريد في المبرد.

- فحص خطوط أنابيب الوقود والمياه بحثا عن أي تسرب أو وصلات مفكوكة.

- ضمان أنظمة السحب والعادم, جنبا إلى جنب مع حشوات الأسطوانة, مختومة بشكل صحيح.

- قم بتنظيف أي بقع زيت أو تراكم غبار على المولد للحفاظ على غرفة ماكينة مرتبة.

خطة صيانة المولدات الاحتياطية

(موصى به للمولدات الاحتياطية المستخدمة في المجتمعات السكنية, المباني التجارية, المستشفيات, المرافق الحكومية, مناطق الجذب السياحي, مصانع, والمواقع الأخرى التي يندر فيها انقطاع التيار الكهربائي.)

الصيانة المهنية (كل ستة أشهر أو سنويا)

بالإضافة إلى الصيانة الروتينية, يجب تقديم خدمة شاملة كل ستة أشهر أو مرة واحدة في السنة:

- إجراء فحص شامل للوقود, كهربائي, تبريد, وأنظمة التشحيم لضمان الأداء الوظيفي المناسب.

- إجراء تشغيل اختبار بدون تحميل ل 5-10 دقائق لتشحيم النظام. تقييم أداء المولد باستخدام الجهاز السمعي, بصري, والفحوصات الشمية.

- استبدال المرشحات الاستهلاكية, بما في ذلك الهواء, الديزل, نفط, الماء, وفواصل الوقود والماء.

- استنزاف واستبدال سائل التبريد, ضمان وظيفة المبرد المناسبة.

- فحص وتجديد إلكتروليت البطارية أو الماء المقطر حسب الحاجة.

- بعد الانتهاء من الصيانة, إجراء فحص نهائي وتنظيف مجموعة المولدات.

- أداء آخر 5-10 اختبار عدم التحميل الدقيق, معلمات أداء التسجيل, وتقديم توصيات التحسين قبل قبول العميل.

خطة صيانة المولدات ذات التشغيل المستمر

(موصى به للمولدات في مواقع البناء, المصانع المعرضة لانقطاع التيار الكهربائي في كثير من الأحيان, المناطق ذات سعة المحولات غير الكافية, مواقع اختبار المشروع, أو المواقع التي لا يمكن الوصول إليها إلى الشبكة الرئيسية.)

مستوى 1 صيانة (كل 50-80 الساعات)

وهذا يشمل جميع مهام الصيانة الروتينية بالإضافة إلى:

- نظف فلتر الهواء واستبدله إذا لزم الأمر.

- استبدل فلتر الديزل, فلتر الهواء, وفلتر المياه.

- افحص شد حزام القيادة واضبطه إذا لزم الأمر.

- قم بتشحيم جميع تركيبات الشحوم والمكونات المتحركة.

- استبدال سائل التبريد للحفاظ على أداء التبريد الفعال.

مستوى 2 صيانة (كل 250-300 الساعات)

يشمل المستوى 1 مهام الصيانة, مع فحوصات إضافية:

- تنظيف وفحص المكابس, دبابيس المكبس, بطانات الاسطوانة, حلقات المكبس, ومحامل قضيب التوصيل للارتداء.

- افحص المحمل الرئيسي بحثا عن أي علامات على الرخاوة أو التآكل غير الطبيعي.

- قم بإزالة الترسبات الكلسية والرواسب من نظام التبريد لضمان تبديد الحرارة بشكل صحيح.

- مسح رواسب الكربون من غرفة الاحتراق وممرات السحب / العادم.

- فحص وضبط خلوص الصمامات, مقاعد الصمام, قضبان الدفع, وأذرع الروك.

- نظف دوارات الشاحن التوربيني وفحص المحامل والدفاعات للتآكل, استبدال إذا لزم الأمر.

- شد أو استبدال أي مسامير مفكوكة أو تالفة في اقتران المولد ومحرك الديزل.

مستوى 3 صيانة (كل 500-1000 الساعات)

يشمل المستوى 1 والمستوى 2 مهام الصيانة, إلى جانب خدمات إضافية:

- تحقق من توقيت حقن الوقود واضبطه.

- تنظيف خزان الوقود لإزالة الملوثات.

- نظف حوض الزيت لمنع تراكم الحمأة.

- فحص واختبار حاقنات الوقود من أجل الانحلال الأمثل.

باتباع خطة الصيانة المنظمة هذه, يمكن لمالكي المولدات ضمان أداء متسق, زيادة العمر الافتراضي, وتقليل مخاطر الإخفاقات غير المتوقعة. فريق الخبراء لدينا في XN-GEN مكرس لتقديم خدمة فائقة للحفاظ على موثوقية مصدر الطاقة الخاص بك في جميع الأوقات.

لمزيد من المعلومات أو لجدولة الصيانة, اتصل بنا اليوم!

1. هل أنت مصنع أو شركة تجارية?

نحن مصنع متخصص في إنتاج أنواع مختلفة من مجموعات المولدات. تضمن منشأة التصنيع الخاصة بنا إنتاجا عالي الجودة ورقابة صارمة على الجودة.

2. ما هي أسواقك الرئيسية?

يتم تصدير منتجاتنا على نطاق واسع إلى أمريكا الجنوبية, الشرق الأوسط, جنوب شرق آسيا, وأفريقيا, تلبية احتياجات الطاقة المتنوعة عبر مختلف الصناعات.

3. كيف تضمن جودة المنتج?

نحن ننفذ تدابير صارمة لمراقبة الجودة في كل مرحلة من مراحل الإنتاج. قبل التسليم, تخضع جميع مجموعات المولدات لاختبار الحمل داخل حاوية الشحن لضمان الأداء الأمثل والموثوقية.

4. ما هي سياسة الضمان الخاصة بك?

تأتي منتجاتنا مع ضمان قياسي في الصناعة لمدة عام واحد أو 1,000 ساعات العمل (أيهما يأتي أولا). كما نقدم خدمات الدعم الفني وقطع الغيار.

5. هل يمكننا تخصيص المولد بشعارنا أو تصميمنا?

نعم! نحن نقدم علامات تجارية مخصصة للشعارات والتصاميم المعتمدة, مما يسمح لك بتخصيص مظهر المولد وفقا لاحتياجات عملك.

6. ما هو وقت التسليم الخاص بك?

وقت الإنتاج والتسليم القياسي لدينا في غضون 15 أيام العمل, اعتمادا على كمية الطلب ومتطلبات التخصيص.

7. كيف يمكنني أن أصبح الموزع الخاص بك?

نرحب بالشراكات مع الشركات التي لديها موارد تسويقية قوية وقدرات خدمة ما بعد البيع. إذا كنت تستوفي هذه المعايير وترغب في التعاون, لا تتردد في الاتصال بنا لمزيد من المناقشات.

8. هل تقدمون دعم ما بعد البيع?

نعم! نحن نقدم المساعدة الفنية, توريد قطع الغيار, واستكشاف الأخطاء وإصلاحها عن بعد لضمان التشغيل السلس لمجموعات المولدات الخاصة بنا.

9: ما هي شروط الدفع التي يمكنك قبولها?

- A: تي / تي, 30% أودع, 70% سيتم دفعها قبل التسليم;

- أو T /, 30% أودع, 70% خطاب الاعتماد في الأفق;

- أو 100% خطاب الاعتماد في الأفق;

XN-GEN.COM

XN-GEN.COM